Full transparent moulding cooler, and its prodn. method and agitator therefor

A production method and mixer technology, applied in frozen sweets, food science, applications, etc., can solve the problems of consumers missing the opportunity to taste delicious food, and achieve the effects of increasing ice and cooling, convenient selection, and increasing cooling and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

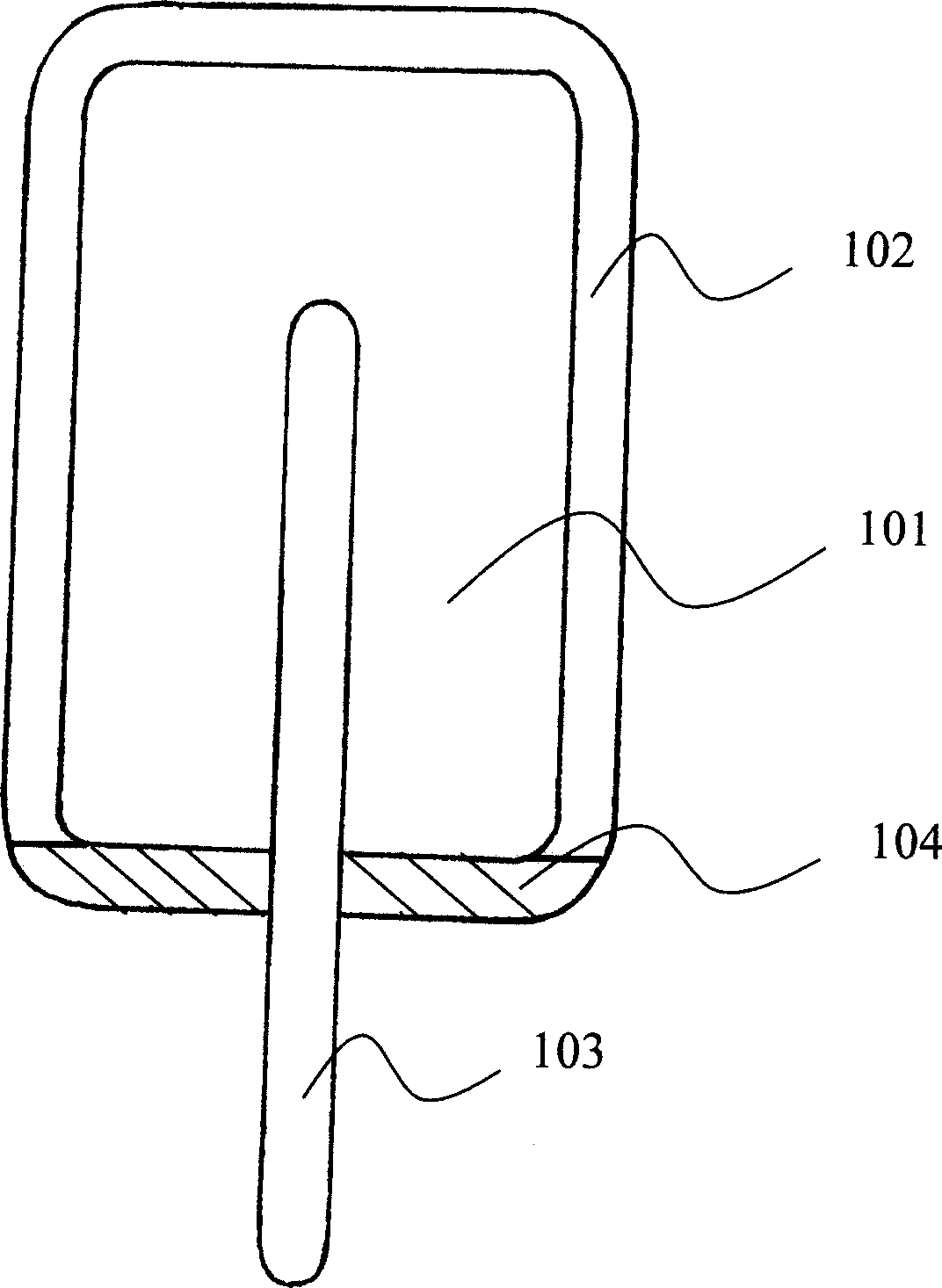

[0050] Such as image 3 As shown, it is a structural schematic diagram of a fully transparent cold drink provided by the present invention. The cold drink includes an internal material 101, and is characterized in that it also includes a layer of ice shell 102, and the ice shell 102 is wrapped on the top of the internal material 101 of the cold drink and around;

[0051] The internal material 101 is any one of ice cream, jam, ice cream or any combination thereof, but the internal material is not limited to the above materials, as long as it is a similar material;

[0052] The ice shell 102 is made of distilled water, deionized water or purified water treated by a reverse osmosis water treatment device to ensure that it is completely transparent after being made, and the inside of the cold drink can be clearly seen through the ice shell 102 Material 101;

[0053] The thickness of the ice shell 102 is 1 mm to 8 mm;

[0054]The cold drink may also include a wooden stick 103 su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com