Chemical diffusion system, chemical diffusion apparatus, chemical diffusion unit and chemical cartilage

A chemical and equipment technology, applied in the field of chemical diffusion system, can solve the problems of not being widely used, time-consuming installation and operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

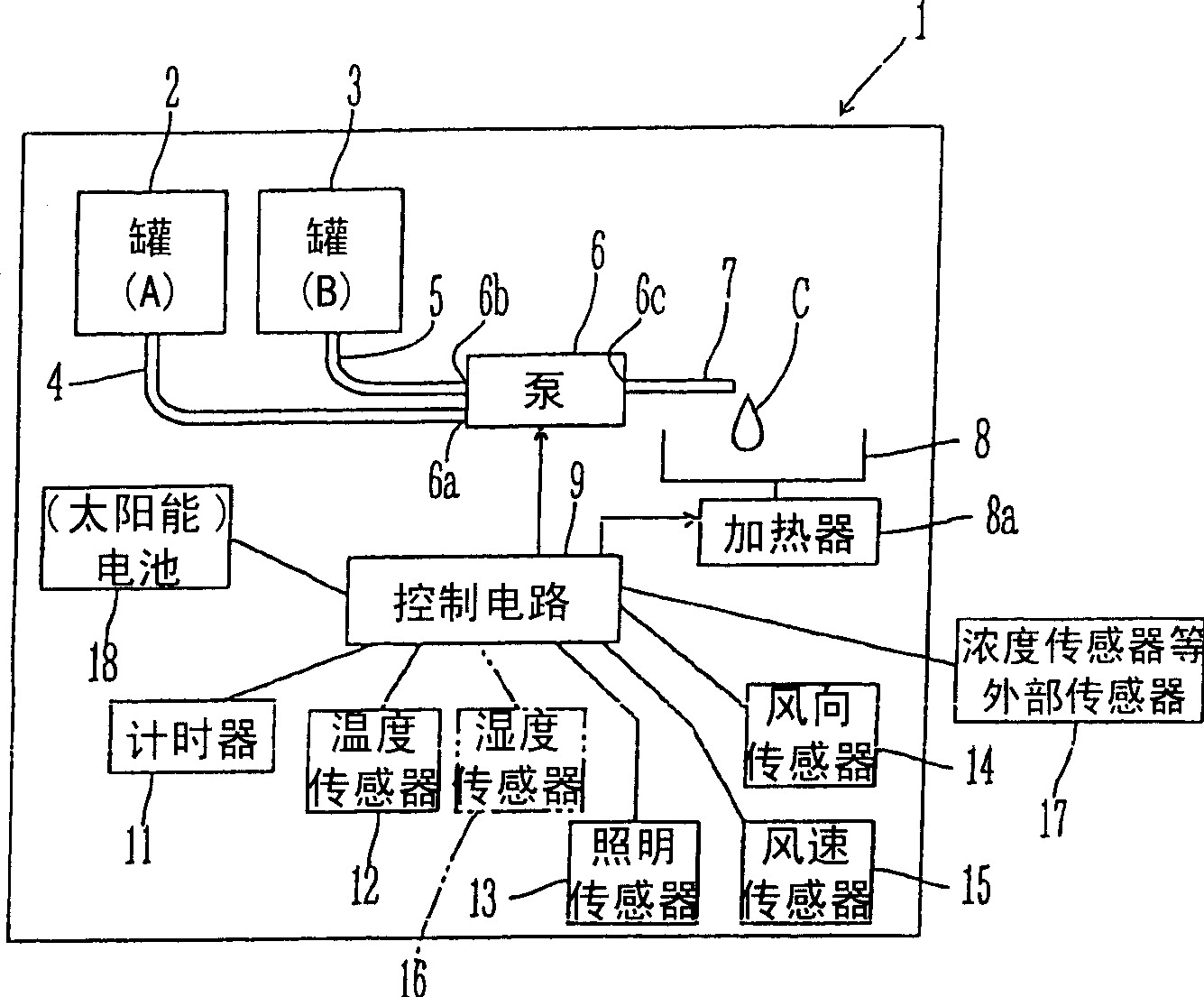

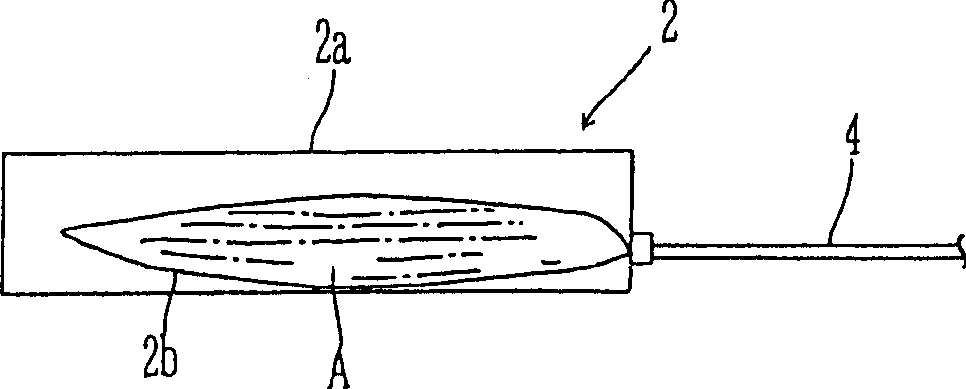

[0075] FIG. 1 is a schematic diagram showing the structure of a chemical diffusion apparatus suitable for dispersing chemicals such as communication disruptors and attractants in a greenhouse or the like. The chemical diffusion device 1 includes a first container 2 filled with a volatile chemical A and a second container 3 filled with a volatile chemical B. Containers 2 and 3 are filled with chemicals A and B in solid or liquid state. The chemicals A and B are supplied from the containers 2 and 3 to the suction holes 6 a and 6 b of the discharge volume variable pump 6 through the chemical supply passages 4 and 5 . Each chemical sucked into the pump 6 is mixed inside the pump 6 and then discharged from the discharge pipe 7 connected to the discharge hole 6c of the pump 6 . The mixed chemicals C are discharged from the discharge pipe 7 onto the evaporation pan 8 serving as a diffusion device. The mixed chemicals C discharged onto the evaporation pan 8 are naturally diffused. ...

Embodiment 2

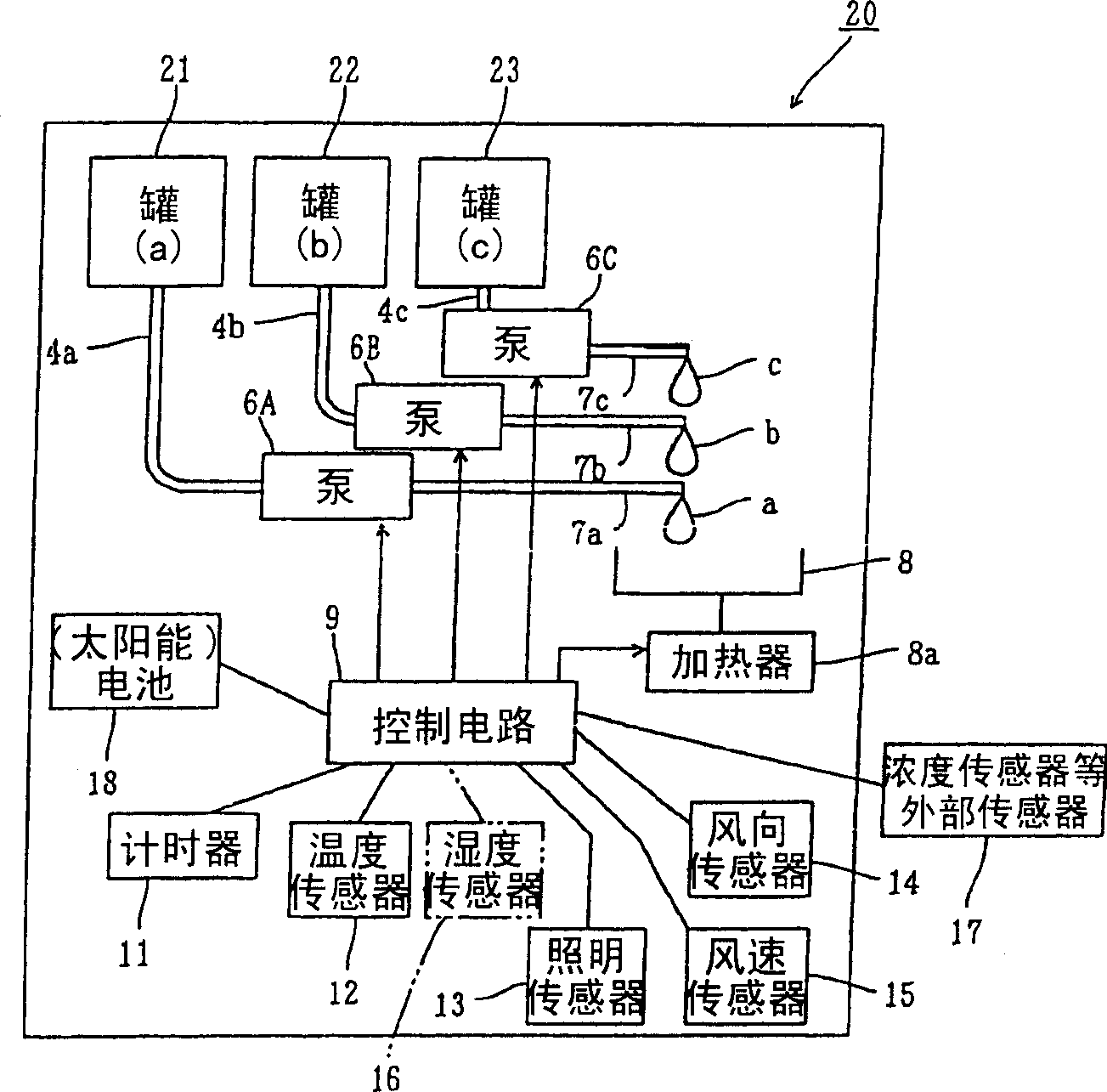

[0084] figure 2 is a schematic diagram showing the structure of a chemical diffusion device according to Embodiment 2. The chemical diffusion apparatus 2 includes a first container 21, a second container 22, and a third container 23, the first to third containers shown serving as chemical containers and filled with chemicals a, b, and c different in composition, respectively. Three pumps 6A to 6C are provided for sucking the corresponding chemicals a to c through the chemical supply passages 4a to 4c, respectively, and discharging the corresponding chemicals a to c from the discharge pipes 7a to 7c. The chemicals a to c are discharged onto the common evaporation pan 8 from the respective discharge pipes 7 a to 7 c. The control circuit 9 is arranged to be able to independently control the driving of the respective pumps 6A to 6C. Descriptions of structures other than the above structures are omitted because they are the same as those of the chemical diffusion apparatus 1 sho...

Embodiment 3

[0092] FIG. 4( a ) is a schematic diagram showing the structure of a chemical diffusion device according to Embodiment 3. FIG. The basic structure of the chemical diffusion device 30 of Embodiment 3 is the same as that of the chemical diffusion device 1 shown in FIG. 1 . Accordingly, corresponding components are denoted by the same reference numerals and descriptions of these components are omitted.

[0093] The chemical diffusion device 30 includes a belt conveyor type diffusion device instead of an evaporation pan. That is to say, the chemical diffusion device 30 includes a belt conveyor 32 and a driving mechanism 33 for driving the belt conveyor 32, the belt conveyor 32 is provided with an endless belt 31, and the endless belt 31 has a structure such as Surface material of felt or sponge. The mixed chemical C is discharged from the discharge pipe 7 onto the endless belt 31 . When the belt conveyor 32 is driven, the endless belt 31 carrying the mixed chemical C moves alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com