Dust collecting apparatus for vacuum cleaner

A technology for dust collectors and vacuum cleaners, applied in suction filters and other directions, can solve problems such as inconvenience in use, affecting the smoothness of airflow in and out, and achieve the effect of extending maintenance cycles and improving convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

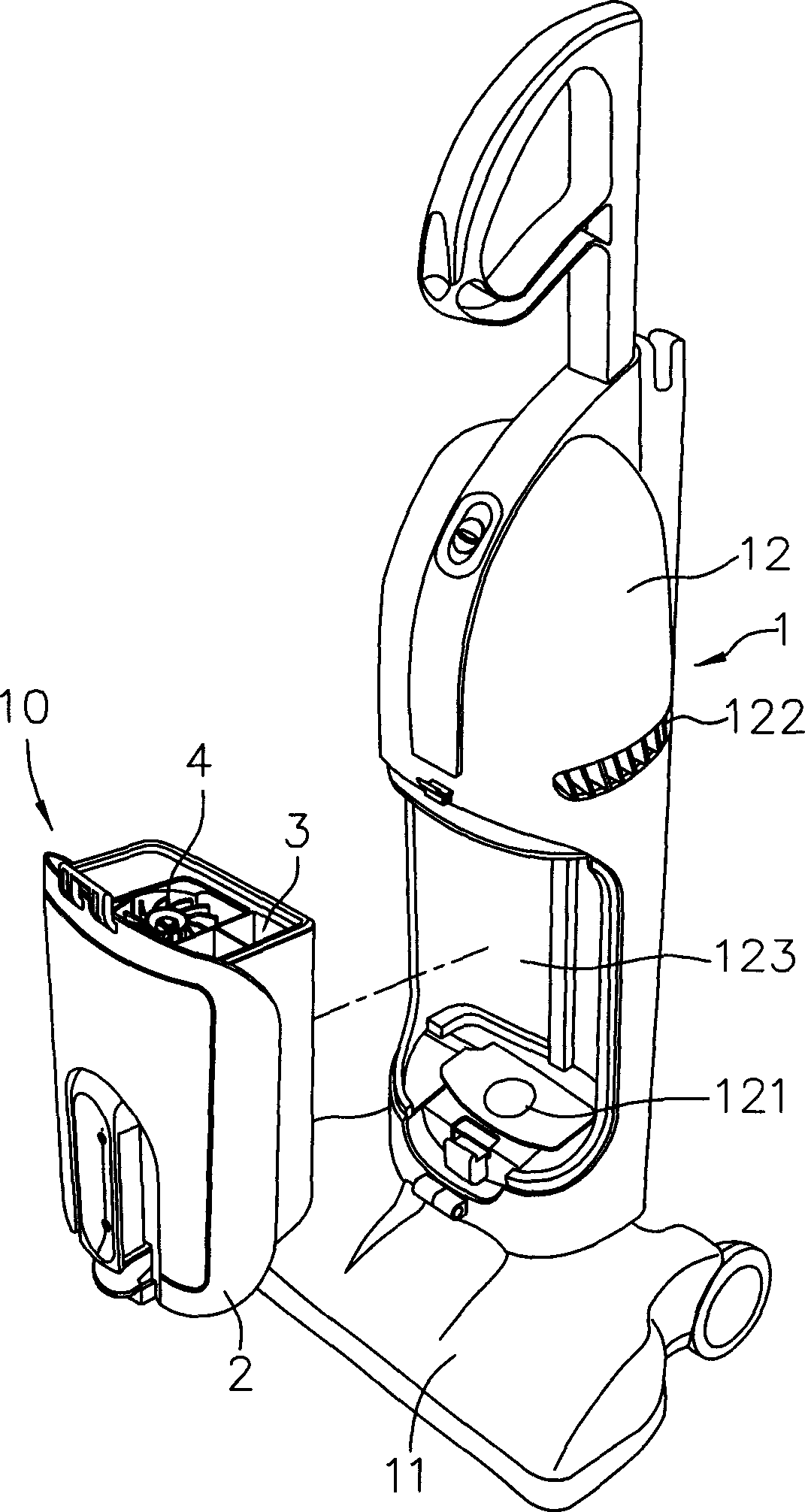

[0017] Refer to figure 1 , 2 3. The first preferred embodiment of the dust collecting device 10 of the present invention is installed on the upright vacuum cleaner body 1. The vacuum cleaner body 1 includes: a dust collector 11 that can move on the ground, and a pivotable The handle 12 is installed above the dust suction part 11, and a motor installed in the handle 12 but not shown in the figure. The motor provides suction so that the dust on the ground below the dust suction part 11 can be After entering an air suction port 121 of the handle portion 12, it is discharged from an air outlet 122 of the handle portion 12. An assembly chamber 123 is recessed between the air suction port 121 and the air outlet 122 of the handle portion 12 In terms of design, the assembly chamber 123 only needs to be located on the path of the air flow in and out, and it is not necessary to be provided on the handle portion 12 in implementation.

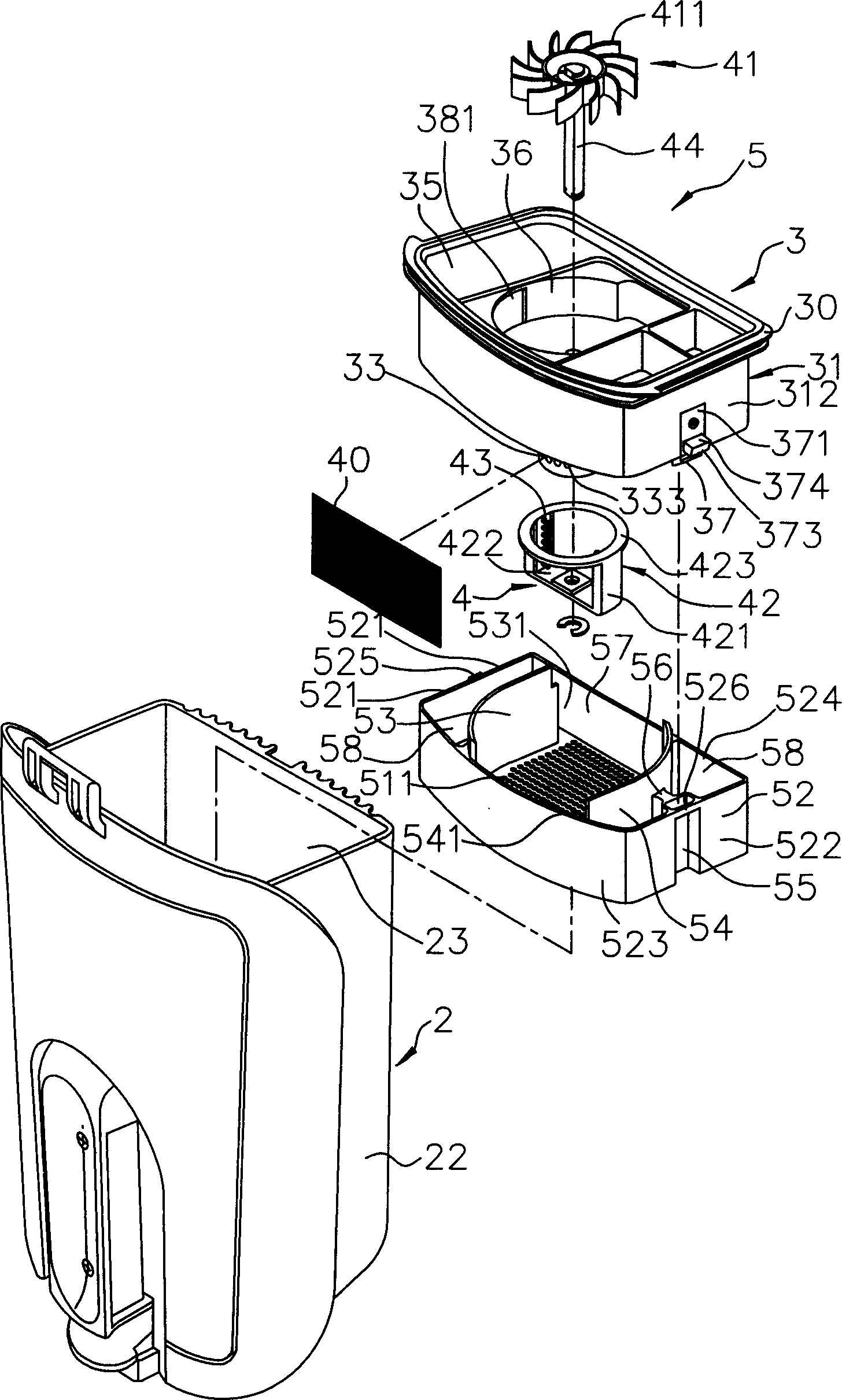

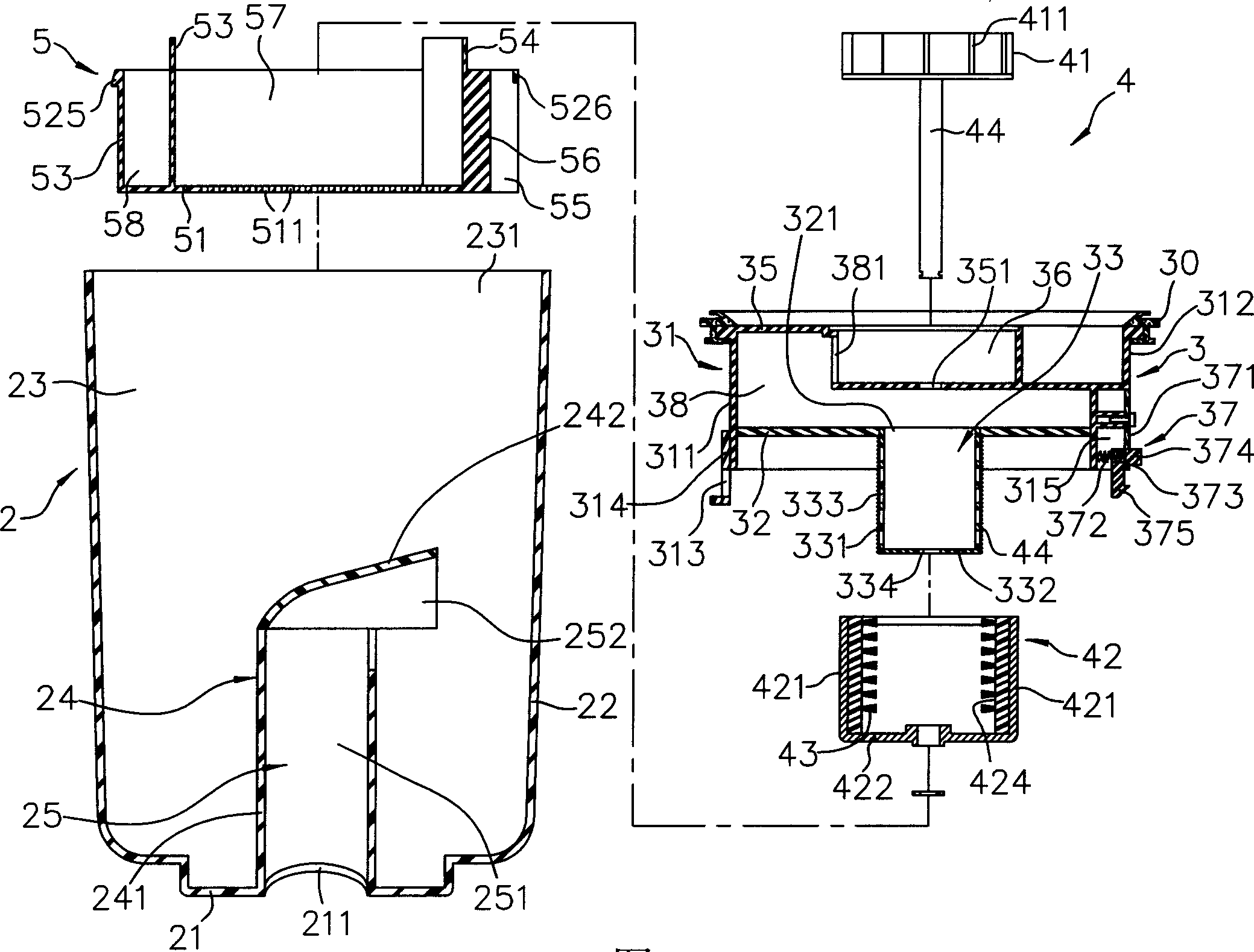

[0018] The dust collecting device 10 of the first prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com