Method for producing automotive frame assembly

A technology of automobile frame and production method, which is applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problems affecting the overall performance of the automobile chassis, improve handling stability and safety, improve handling stability, and eliminate welding stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

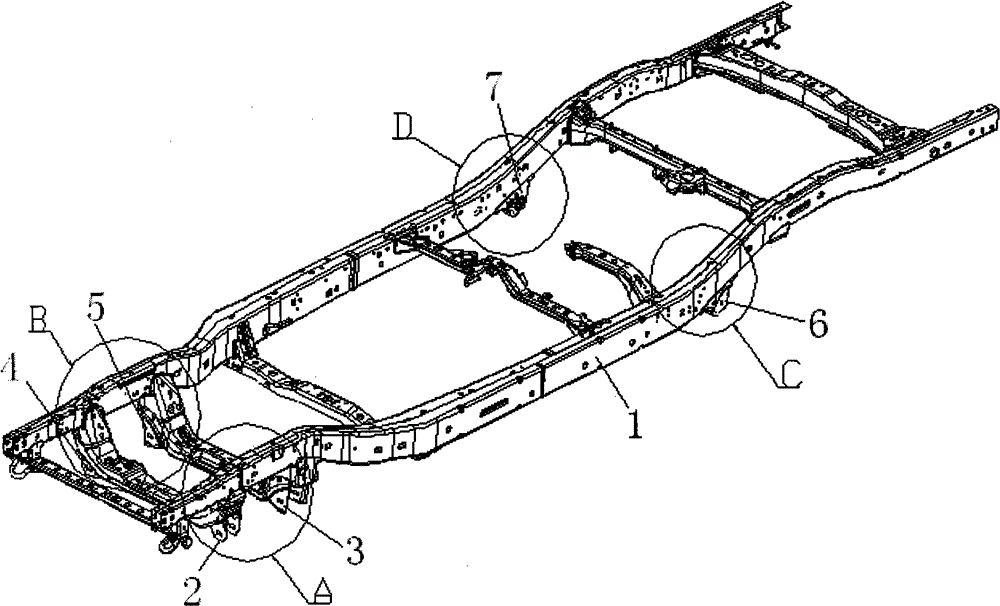

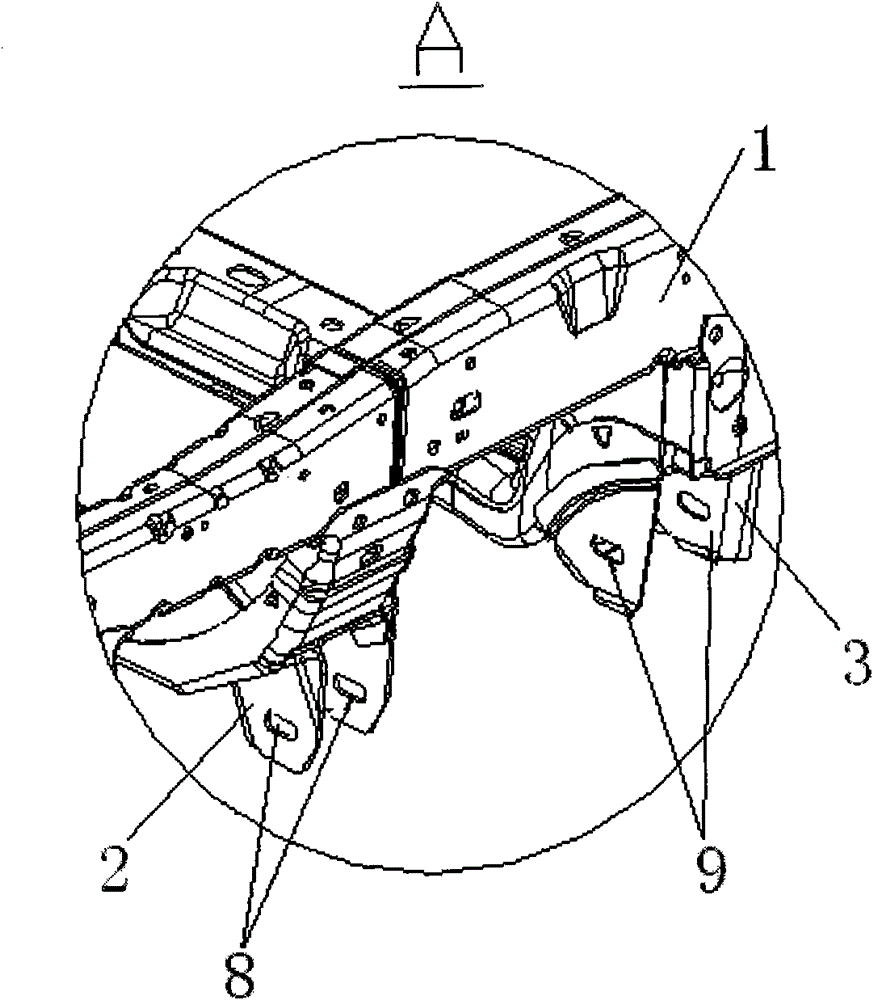

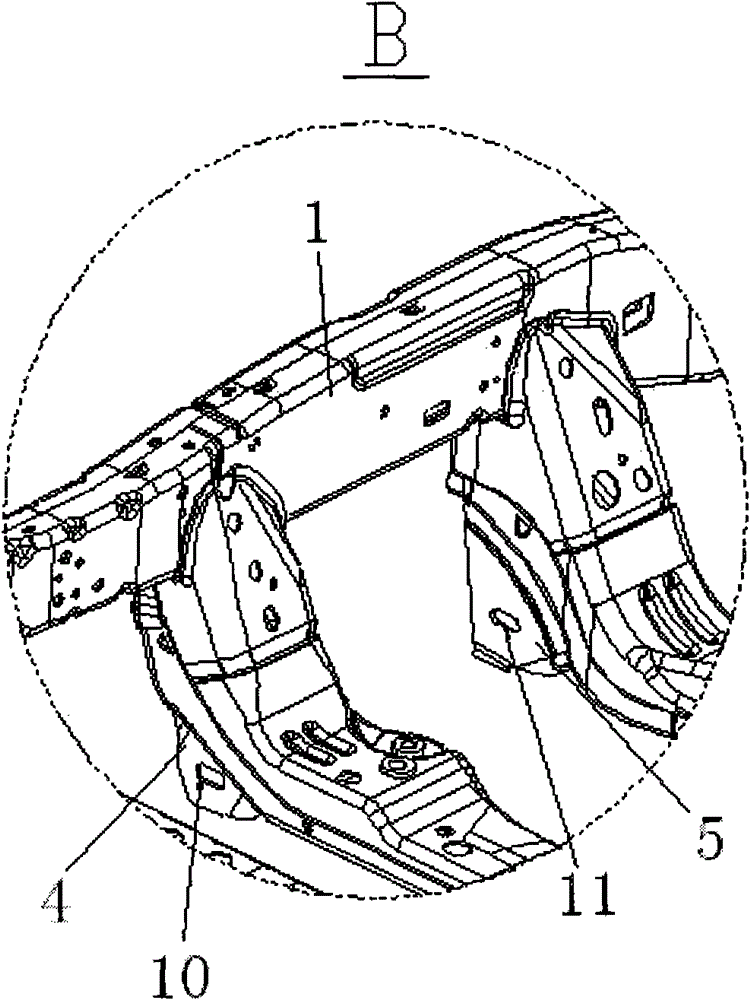

[0044] Before describing the preferred embodiments of the present invention, it should be noted that in the following, some orientation words used for the convenience of description, such as "left", "right", "front", "rear", etc., all have the meaning According to the orientation usually indicated after the car is assembled, for example, in figure 1 When the frame assembly 1 is assembled into a car, part A and part C in the figure are on the left side of the car, while part B and part D in the figure are on the right side of the car; part A and part B It is at the front of the car, while part C and part D are at the rear of the car. The positional relationship between other corresponding parts can be deduced by analogy. In addition, the “lower arm of the frame” referred to in the present invention is a component of the automobile suspension system, and the “under” means that it is installed under the frame.

[0045] The automobile frame assembly generally includes a longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com