Vacuum electron beam welding method for thin-walled titanium alloy assembly

A technology of vacuum electron beam welding and vacuum electron beam, applied in electron beam welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of low qualification rate, high requirements on the coaxiality of parts, and difficult process technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The material used for the welding test is a TC11 thin plate with a thickness of 2.0mm, and its chemical composition is shown in Table 1:

[0044] alloy element,%

Impurities, %, not greater than

Al

Mo

Zr

Si

Ti

Fe

C

N

H

O

sum of other

5.8~7.0

2.8~3.8

0.8~2.0

0.20~0.35

margin

0.25

0.10

0.05

0.012

0.15

0.3

[0045] The welding test equipment is KS120-G300KM vacuum electron beam welding machine: high voltage 90-150KV, with 16 kinds of waveforms, and a large frequency modulation range.

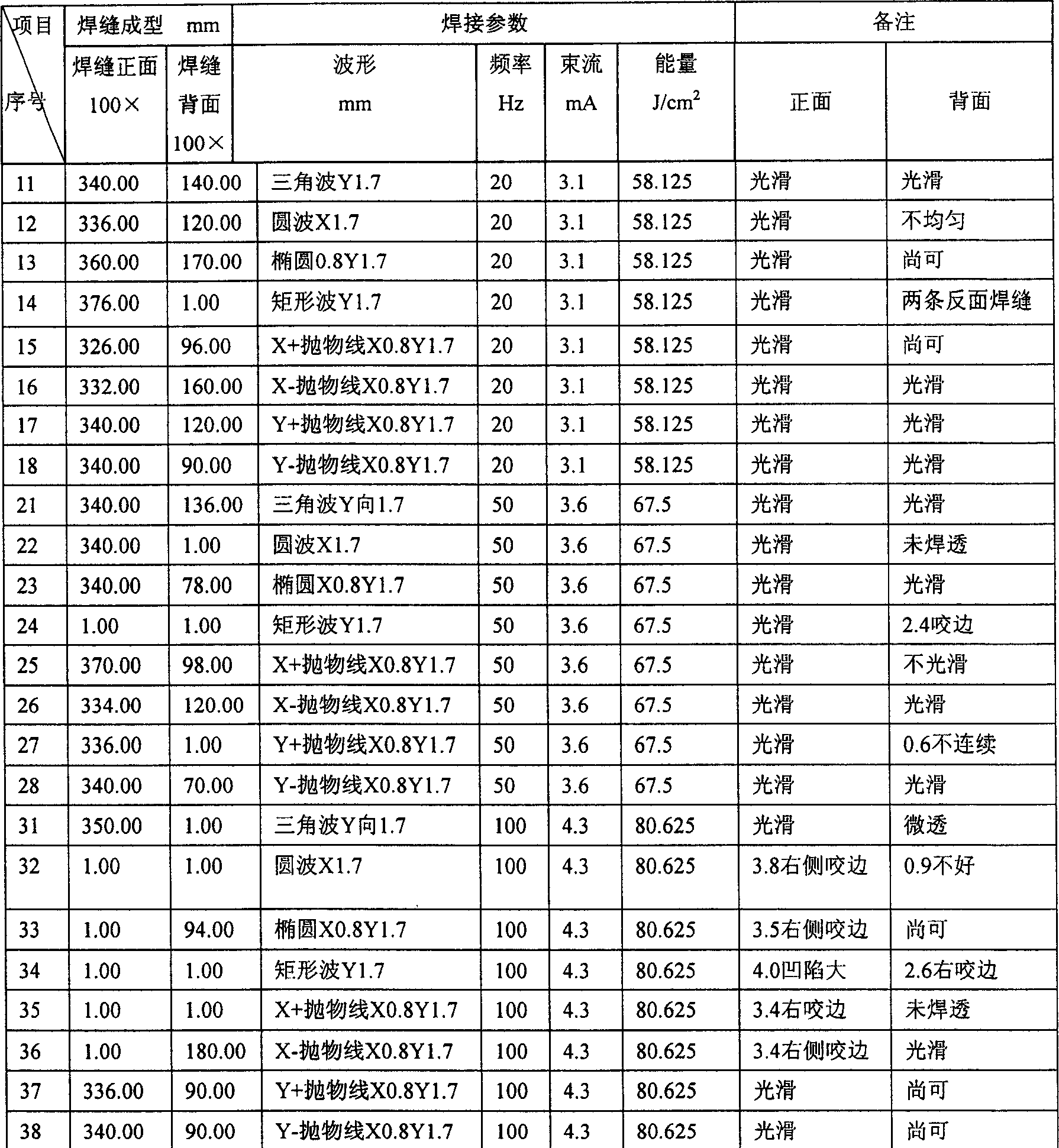

[0046] A large number of tests have been carried out by using different welding parameter combinations for TC11 plates with the same thickness and the same state. Some data are shown in Table 2 and Table 3.

[0047] Table 2150KV same frequency variable waveform welding parameter table

[0048]

[0049] Table 3 Triangular wave acceleration volta...

Embodiment 2

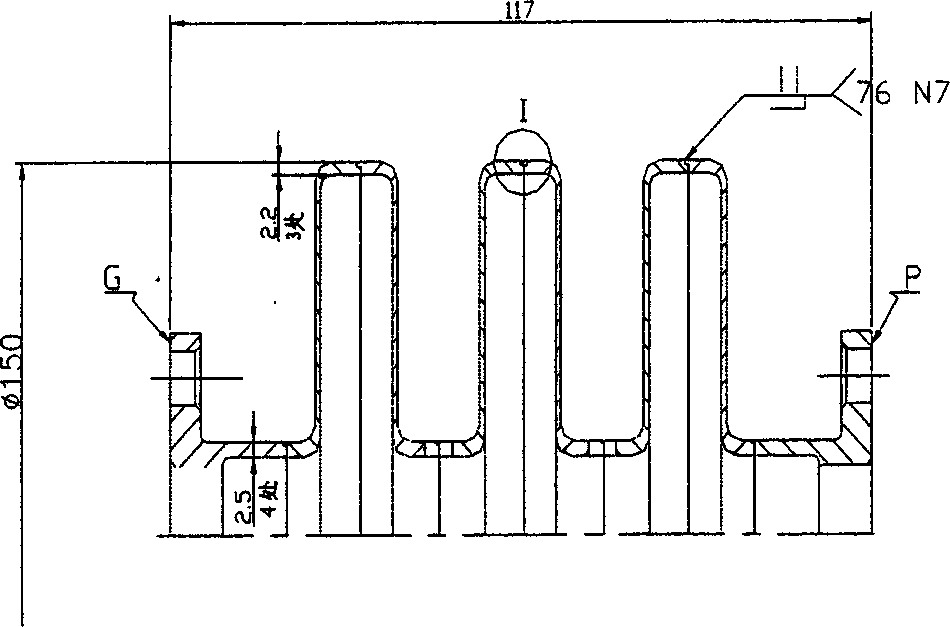

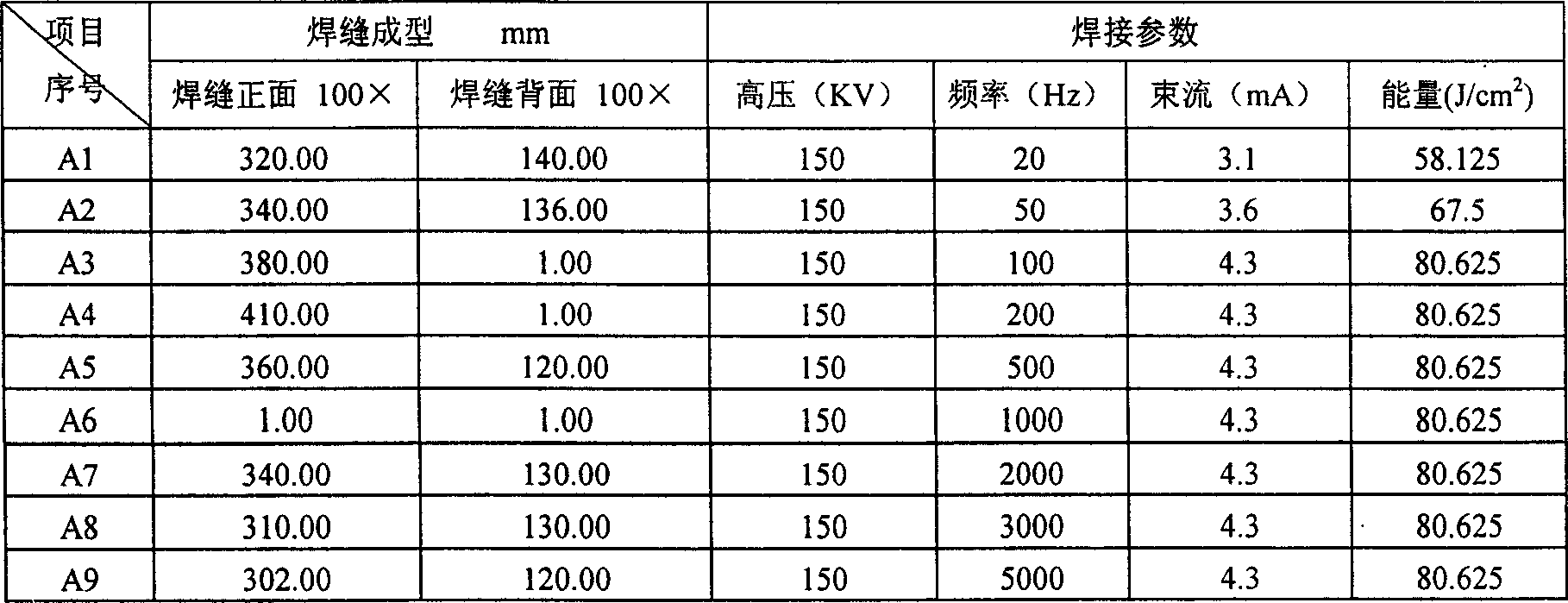

[0053] Welding of aircraft engine bellows, bellows structure see figure 1 , Assemble the single box of the same group on the single box welding tool, check the assembly quality, and after confirming that it is correct, vacuumize to 2×10 -2 Above Pa, tack welding is performed first, then seal welding, then penetration welding, and finally finishing welding. The welding parameters are shown in Table 4. Out of the warehouse, the appearance inspection of the weld seam (the inner cavity can be carried out with the help of a lens), and the welding of the next single piece is carried out after passing the standard. Each set of bellows components has three single boxes.

[0054] Table 4 Diaphragm assembly single box (Φ150) vacuum electron beam welding parameter list

[0055]

[0056] Assemble the three single boxes and two flanges that are qualified for welding, and vacuumize to 2×10 -2 Above Pa, tack welding is performed first, then seal welding, then penetration welding, and f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com