CD drive disc and its manufacturing method

A technology of an optical disc drive and a manufacturing method, which is applied in the directions of instruments, record carrier structural parts, data recording, etc., can solve the problems of disrupting the smooth flow of fluid, loud noise, sudden change in the area of air through holes, etc., and achieves the effect of reducing fluid vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

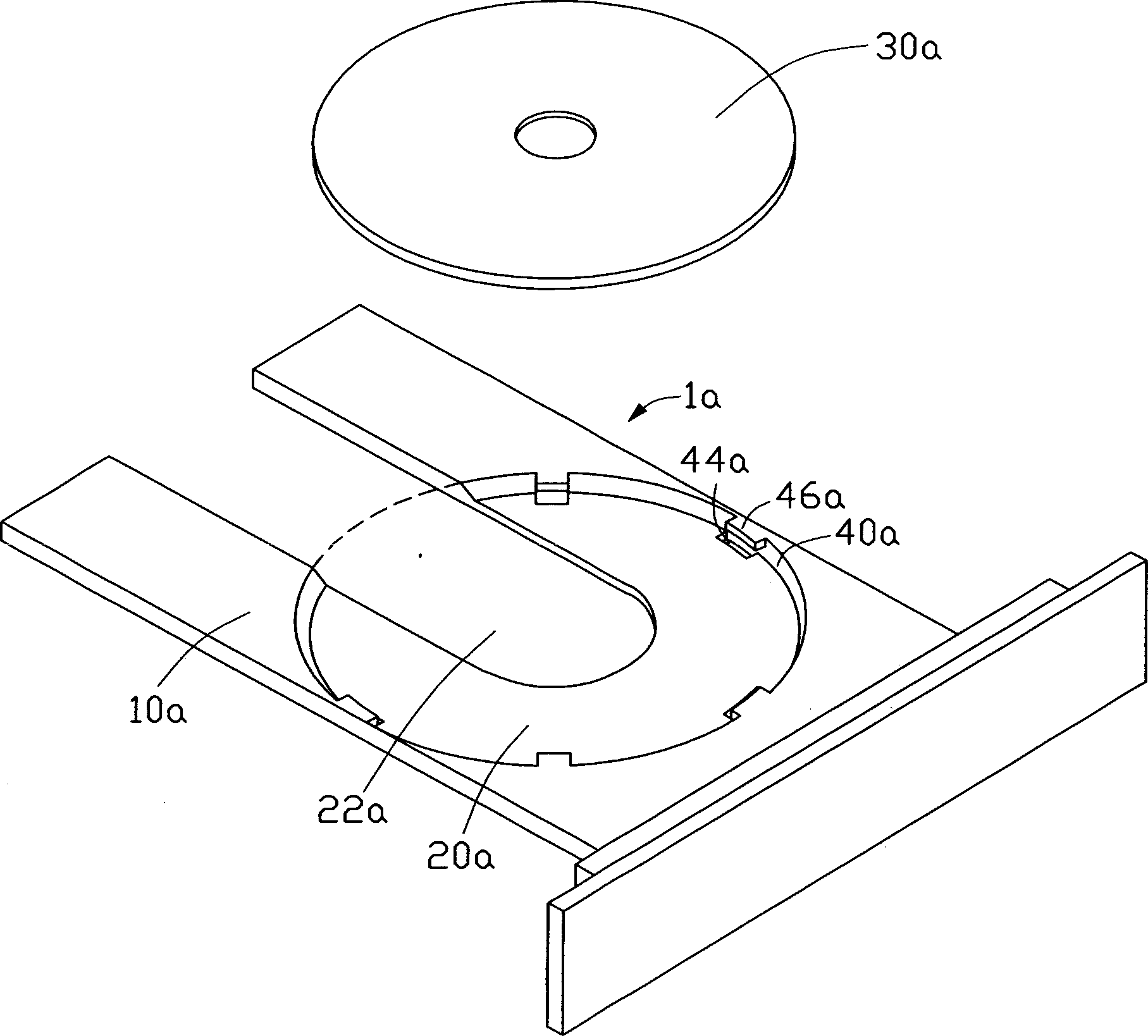

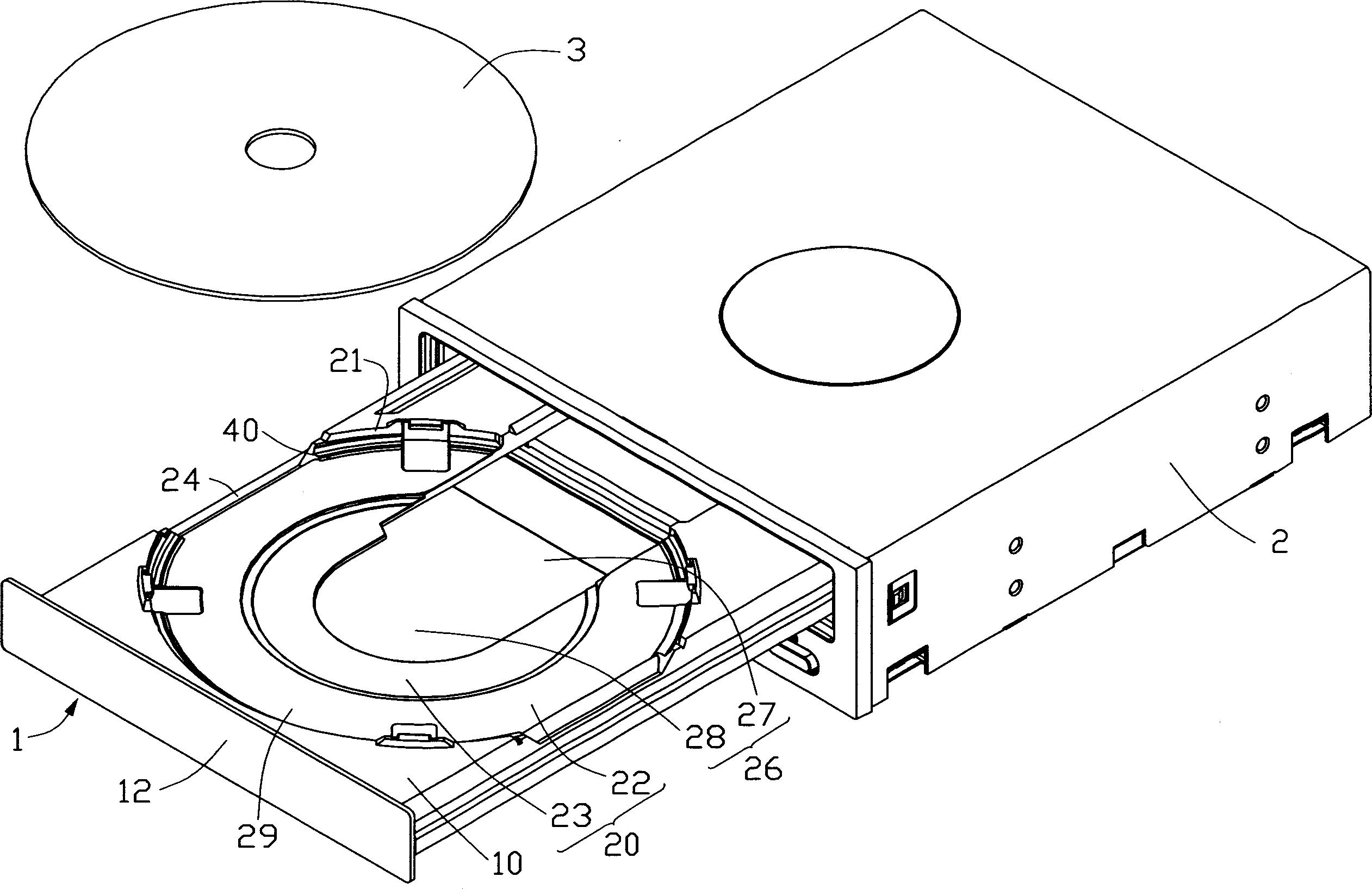

[0019] See image 3 The optical disc drive tray 1 of the present invention can be installed in an optical disc drive 2. The tray 1 can be slid into / out of the optical disc drive 2 to output / input the optical disc 3 carried thereon to the optical disc drive 2.

[0020] The tray 1 includes a substantially rectangular main body 10, and a baffle 12 is provided at the front end of the main body 10. When the tray 1 is placed inside or outside the optical disc drive 2, the baffle 12 can facilitate the tray 1. In and out of the optical drive 2, it can also play a role of dustproof when the tray 1 is placed in the optical drive 2. The rear end of the main body 10 is always accommodated in the optical disc drive 2.

[0021] The central portion of the main body 10 is recessed downward to form an optical disc accommodating area 20, so that a first side wall 21 perpendicular to the optical disc accommodating area 20 is formed between the optical disc accommodating area 20 and the main surface ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap