Method and device for dye solution infiltrating better during dyeing

A dyeing device and dyeing solution technology, applied in the field of dyeing methods and dyeing equipment, can solve problems such as poor exchange and suboptimal dye solution exchange, and achieve the effect of improving the exchange effect and improving the penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

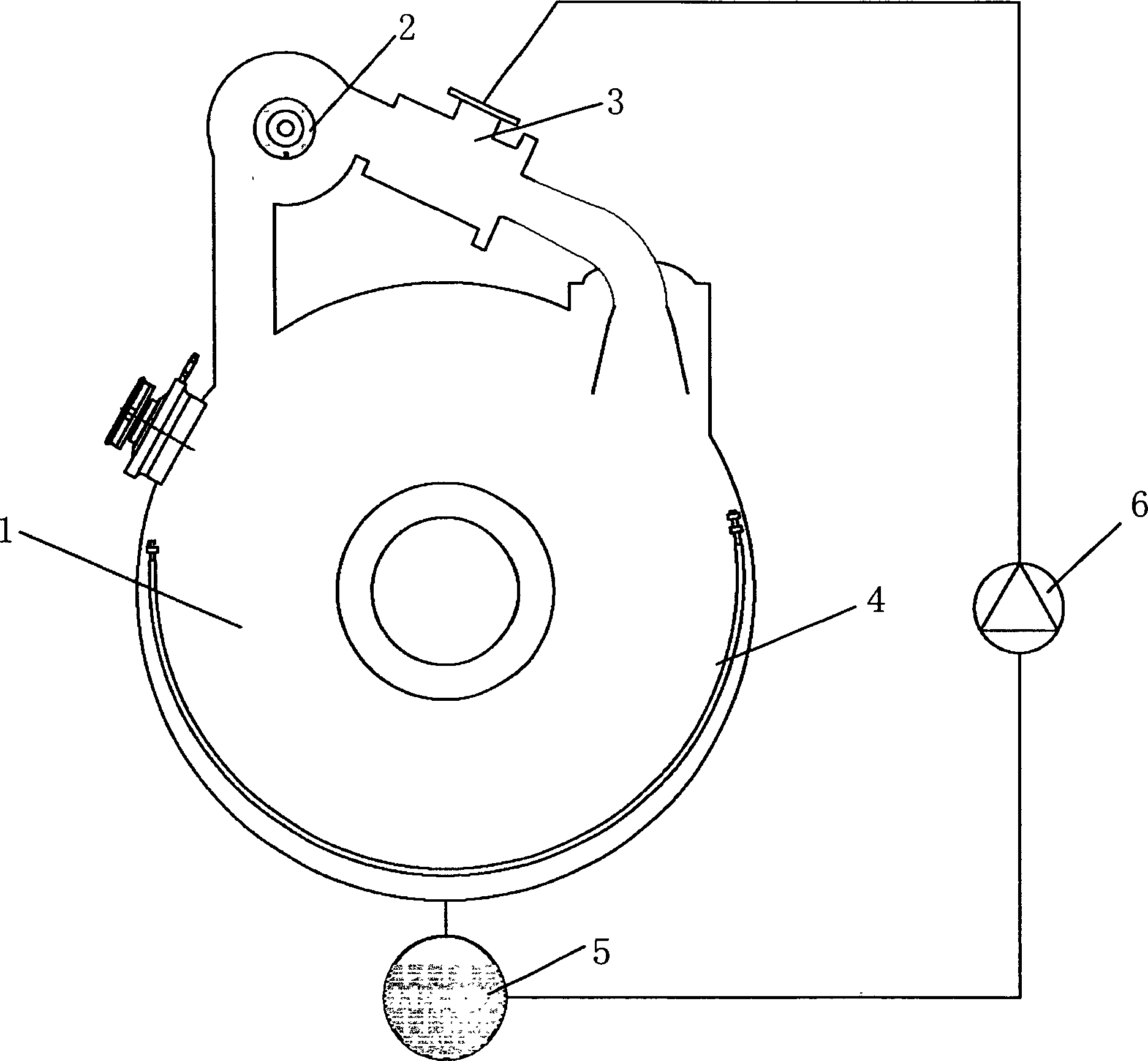

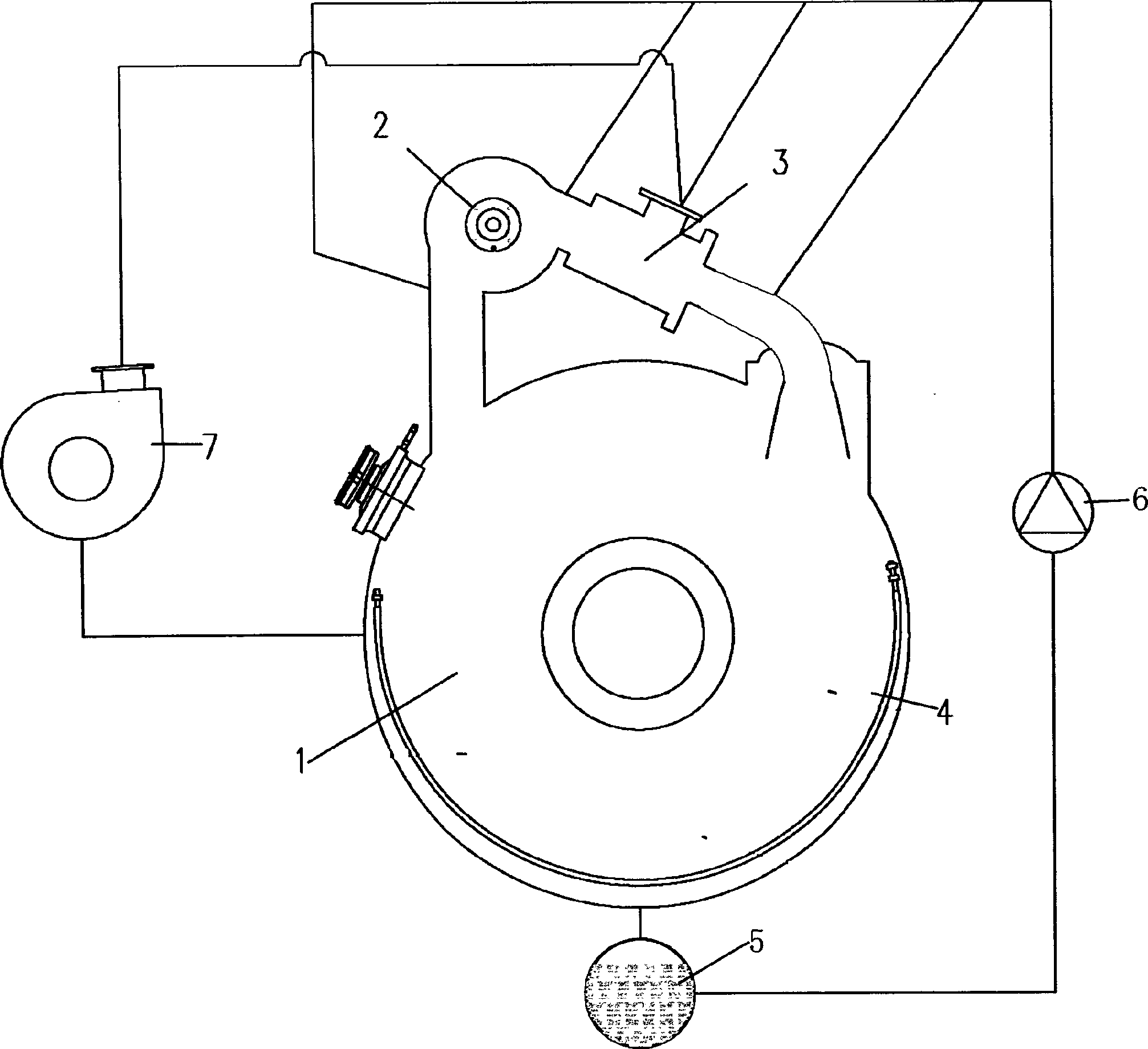

[0043] In one embodiment of the technical solution of the present invention, adopt figure 2 The basic structure of the dyeing machine shown is a pneumatic dyeing machine, which includes a pressure-resistant cylinder, a cloth shaft 2, a transmission medium nozzle 3 (air flow nozzle), a cloth storage chamber 4, a dye liquor tank 5, a pump 6 and a blower 7, etc. Wherein, the fabric bundle 1 is joined into a loop of the fabric bundle 1 that can be circulated in the dyeing machine barrel. The cloth beam 2 pulls the fabric bundle 1 upwards and introduces a pressurized transport medium such as air flow (air or a mixture of air and steam) through air flow nozzles 3 . The blower 7 draws air or a mixture of air and steam from the dyeing machine cylinder and presses it into the transfer medium nozzle 3 . In this way, the fabric circulates in the cylinder of the dyeing machine through the cloth shaft and the airflow introduced into the nozzle 3 . The pump 6 sucks the dye solution from ...

Embodiment 2

[0045] In another embodiment of the technical solution of the present invention, also adopt figure 2 The basic structure of the dyeing machine shown is a pneumatic dyeing machine, which includes a pressure-resistant cylinder, a cloth shaft 2, a transmission medium nozzle 3 (air flow nozzle), a cloth storage chamber 4, a dye liquor tank 5, a pump 6 and a blower 7, etc. Wherein, the fabric bundle 1 is joined into a loop of the fabric bundle 1 that can be circulated in the dyeing machine barrel. The cloth beam 2 pulls the fabric bundle 1 upwards and introduces a pressurized transport medium such as air flow (air or a mixture of air and steam) through air flow nozzles 3 . The blower 7 draws air or a mixture of air and steam from the dyeing machine cylinder and presses it into the transfer medium nozzle 3 . In this way, the fabric circulates in the cylinder of the dyeing machine through the cloth shaft and the airflow introduced into the nozzle 3 . The pump 6 sucks the dye solut...

Embodiment 3

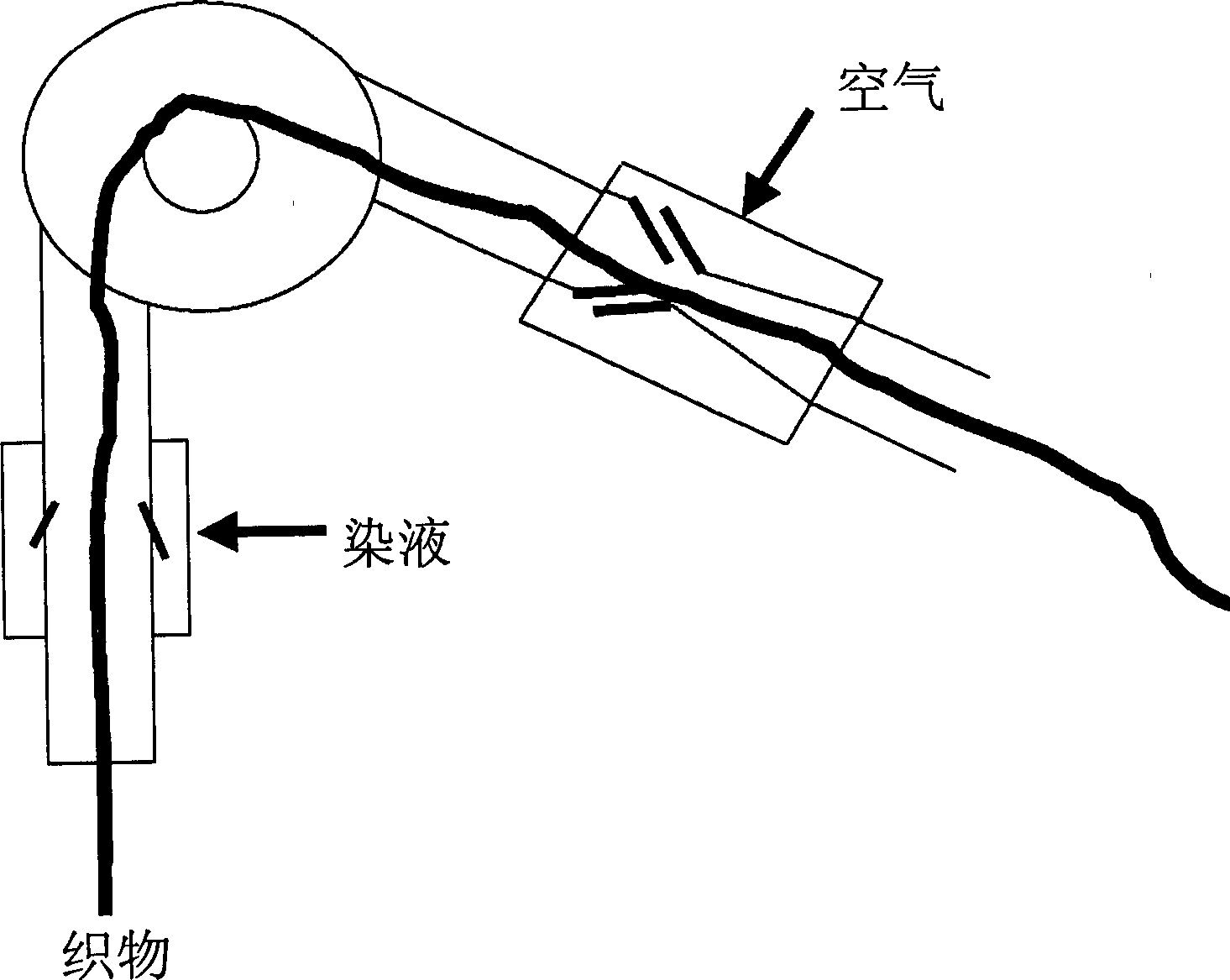

[0047] Implementation in the present embodiment is basically the same as in Example 1, except that the dye solution nozzle is arranged after the air flow nozzle 3, and the dye solution flow sprayed onto the fabric bundle 1 is against the moving direction of the fabric bundle 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com