Cylinder lock

A plunger, unlocking technology, applied in the direction of building locks, buildings, building structures, etc., can solve the problems of inability to perform unlocking operations, complicated operations, etc., and achieve the effect of improving the efficiency of assembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

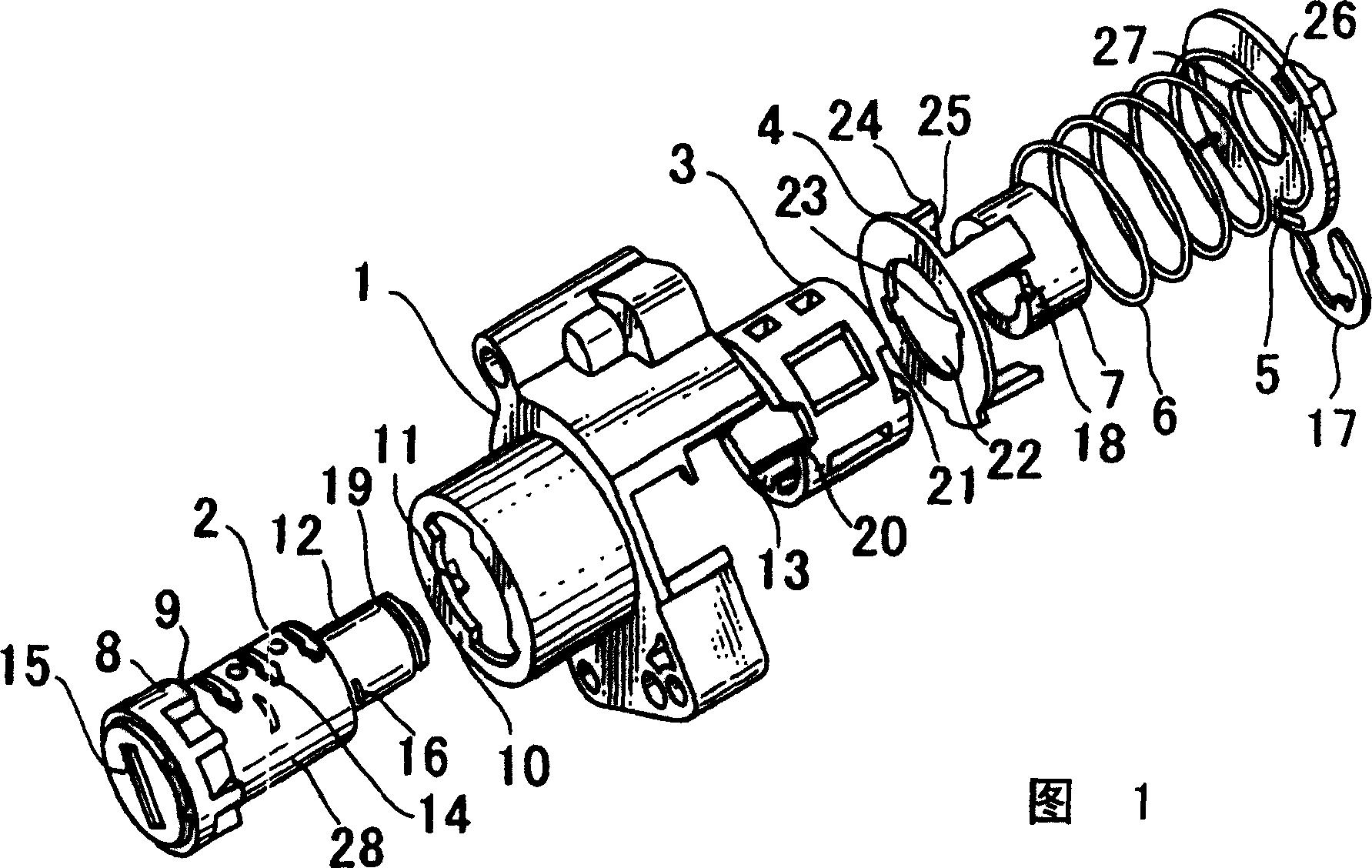

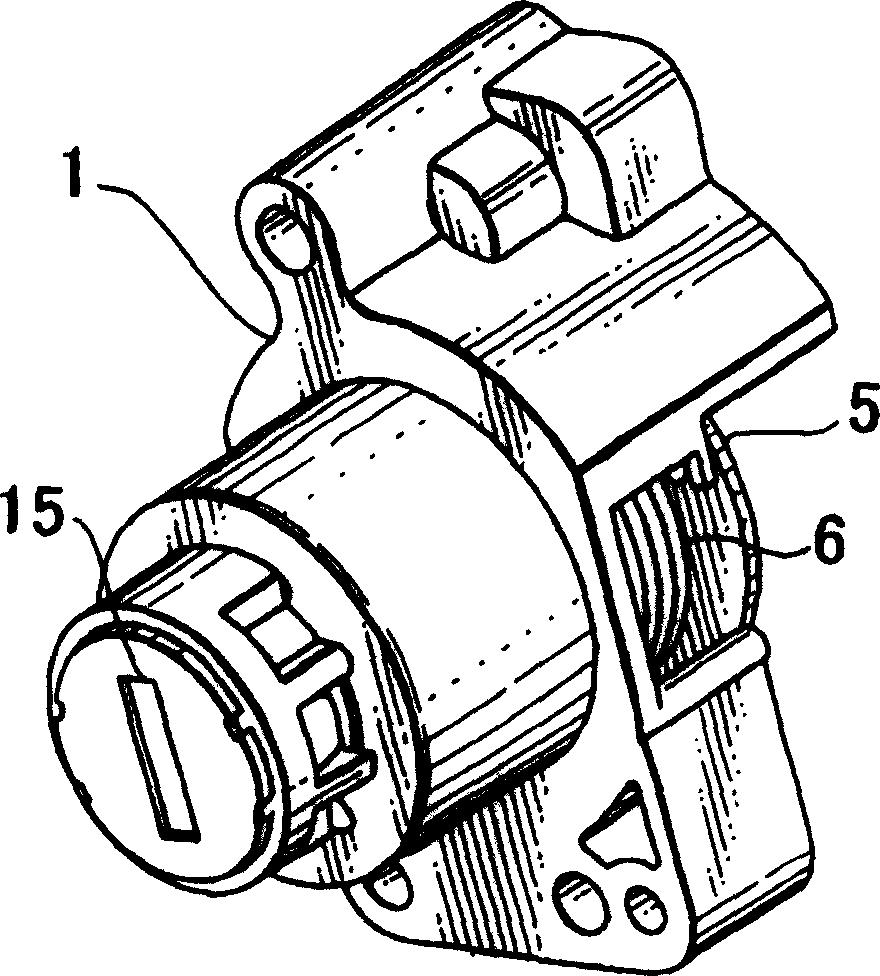

[0048] [Example 1]( figure 1 to Figure 4)

[0049] Such as figure 1 and figure 2 As shown, the plunger lock according to Embodiment 1 of the present invention includes a housing 1, a rotor 2, a cylindrical plunger 3, an unlocking element 5, a connecting piece 4, a return spring 6 and a collar 7, and the housing 1 is fixed on the On the opening / closing part of the vehicle, the rotor 2 has a stepped diameter and is rotatably installed in the housing 1, with a retractable tumbler, the plunger 3 is rotatably arranged between the rotor 2 and the housing 1, and the unlocking element 5 is connected The rear end of the rotor 2 , the connecting piece 4 and the return spring 6 are detachably mounted on the rear end of the rotor 2 , and the collar 7 is located between the connecting piece 4 and the return spring 6 .

[0050] More specifically refer to figure 1Each component has adjoining portions 10 opposite to each other on the outer periphery of the front edge of the housing 1 , w...

Embodiment 2

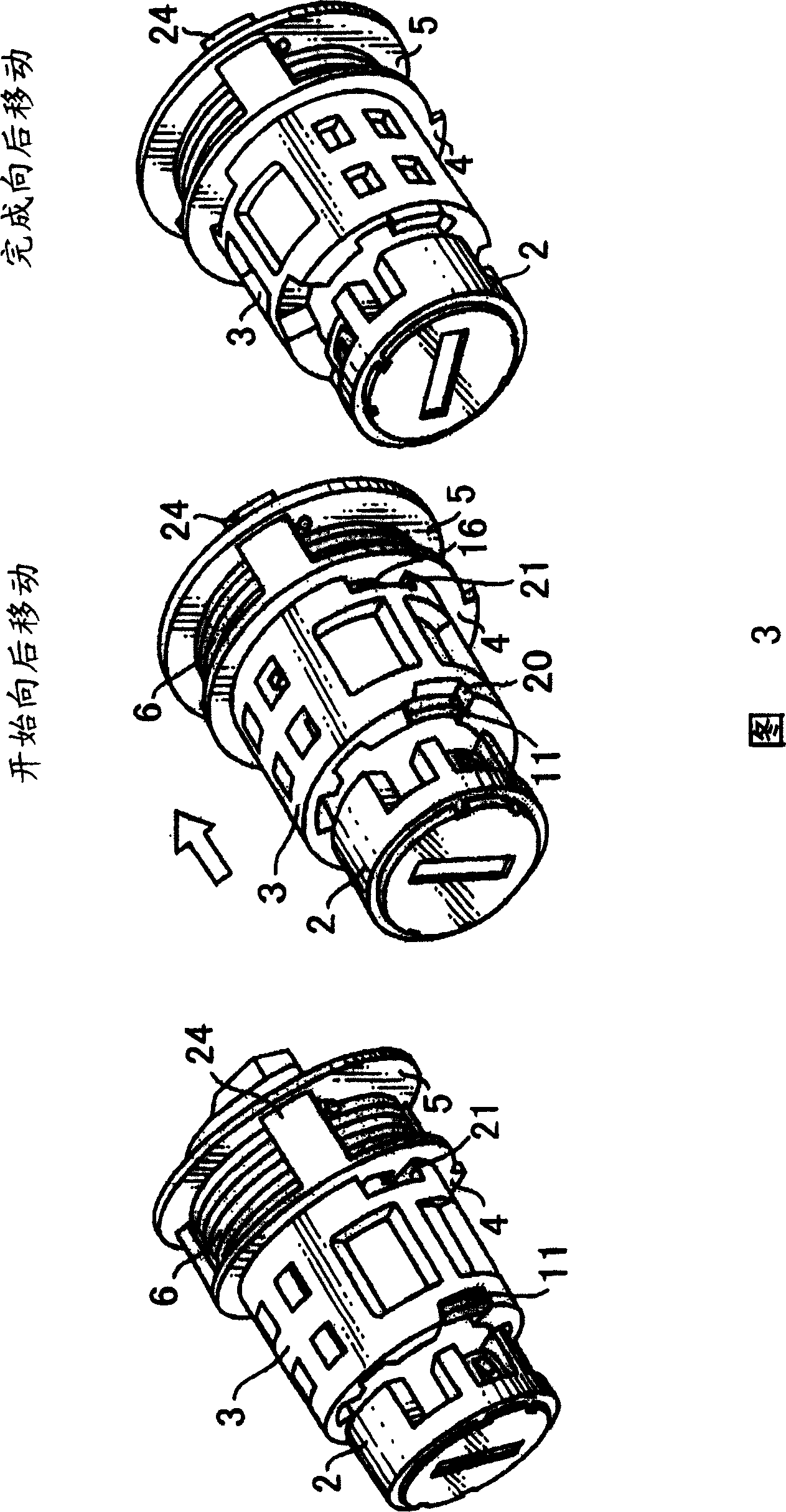

[0067] [Example 2] ( Figure 5 to Figure 15 )

[0068] Embodiment 2 and additional modified embodiments according to the present invention will be described below with reference to the drawings.

[0069] Embodiment 2 and the like have the following technical features: that is, the connecting piece, spring, and unlocking element in Embodiment 1 are assembled into a whole in advance, so as to facilitate the assembly operation of the plunger lock.

[0070] Such as Figure 5 and Figure 6 As shown, the plunger lock according to Embodiment 2 of the present invention includes a housing 101, a rotor 102, a cylindrical plunger 103, an unlocking element 105, a connecting piece 104, a return spring 106 and a collar 107, and the housing 101 is fixed as On the opening / closing part of the vehicle of the base body, the rotor 102 has a stepped diameter and is rotatably installed in the housing 101, with a retractable tumbler, the plunger 103 is rotatably arranged between the rotor 102 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com