Method for the production of a bipolar semiconductor component and corresponding bipolar semiconductor component

A bipolar transistor and semiconductor technology, applied in the field of bipolar transistors and bipolar semiconductor components, can solve the problem that transistors are not suitable for high-performance transistors, and achieve the effect of improving electrical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

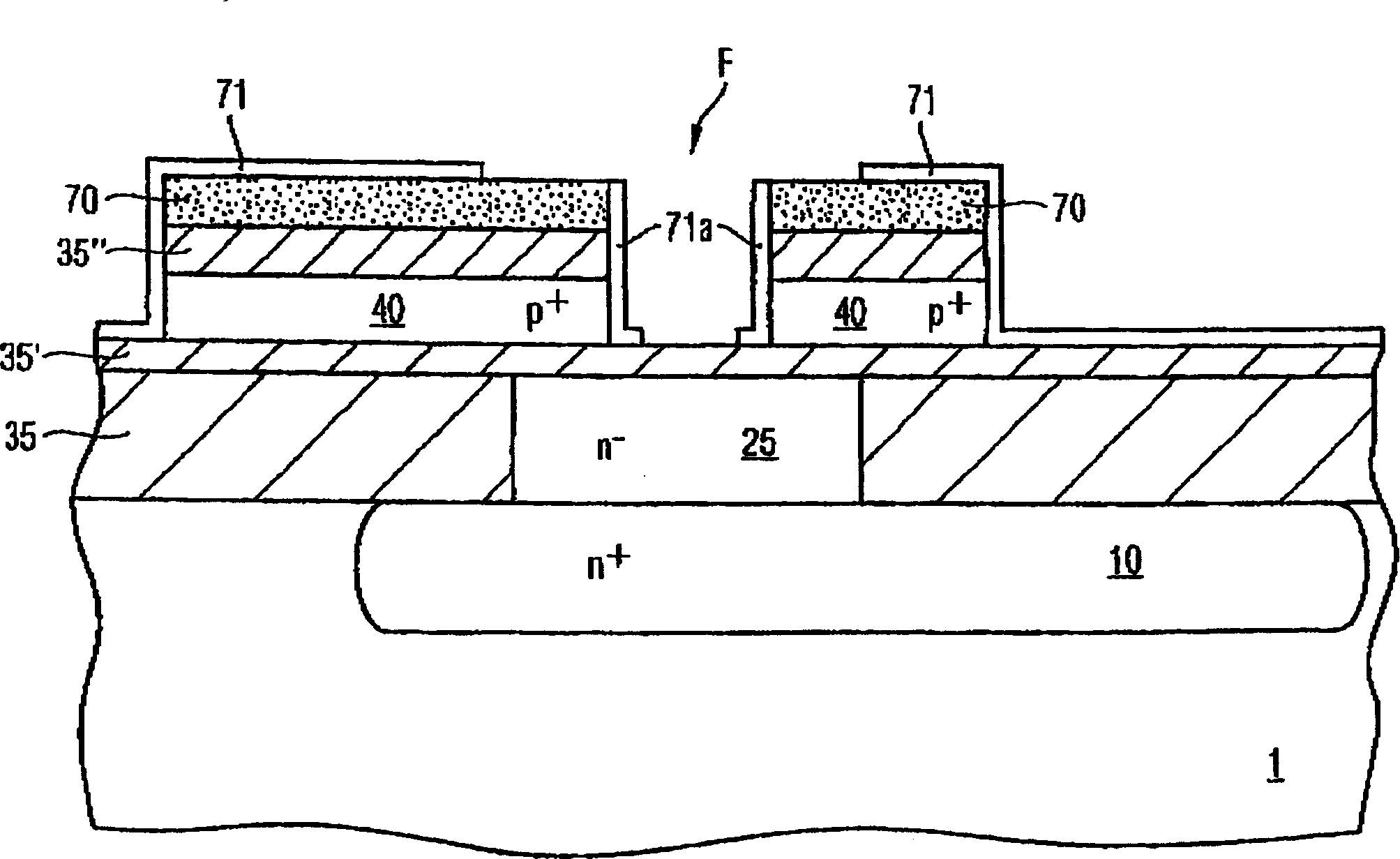

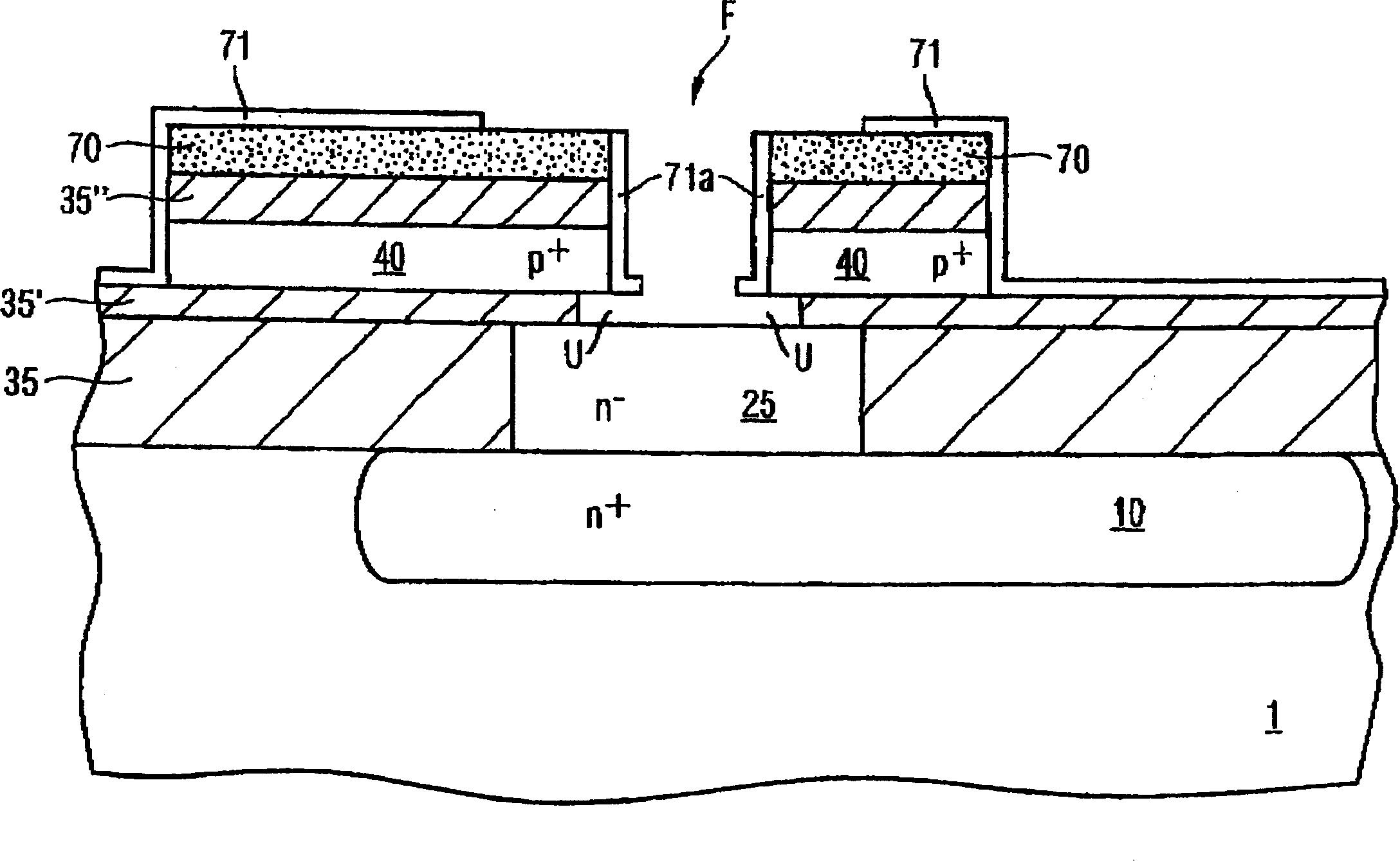

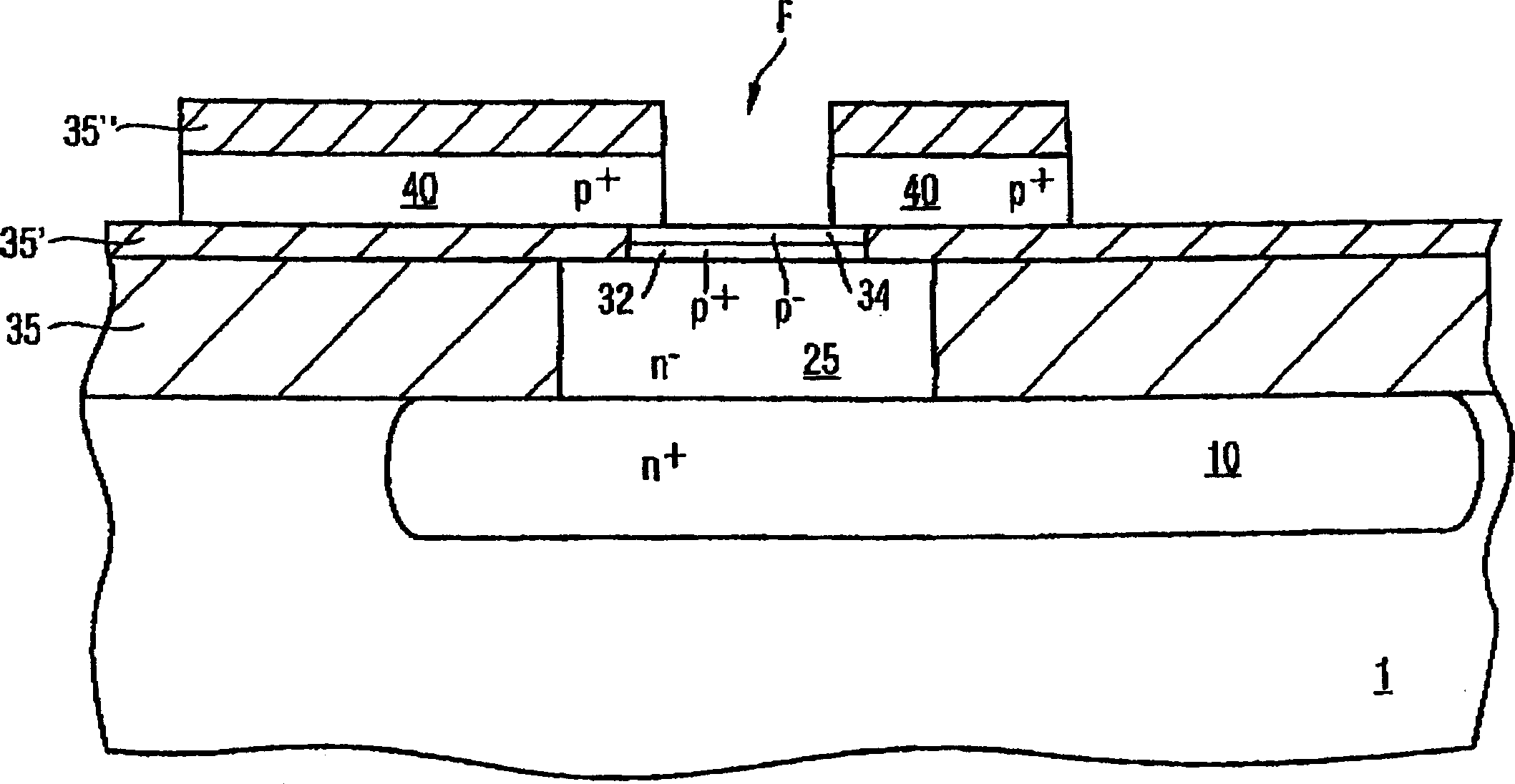

[0028] The idea on which the invention is based begins with Figure 3C . It is known that the emitter and base electrodes 60, 40 of the DPSA transistor and the intervening dielectric of the spacer 55' form a capacitor whose capacitance Csp increases the emitter-base capacitance CBE of the transistor. The latter is one of the most important performance-determining variables for bipolar transistors. Therefore, the following equations apply, e.g. for the transition frequency of a bipolar transistor:

[0029] 1 2 π f T = τ f + ( R C + R E ) C BC + C BE ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com