Text and graph roller printing process and apparatus for metal powder painting part

A technology of metal powder and process method, which is applied in the field of rolling printing process and equipment of texture images and texts of metal powder sprayed parts, can solve the problems of restricting the visual appearance of sprayed parts, the retention is not long, and it cannot be easily obtained, etc. Strong stereoscopic effect and long lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

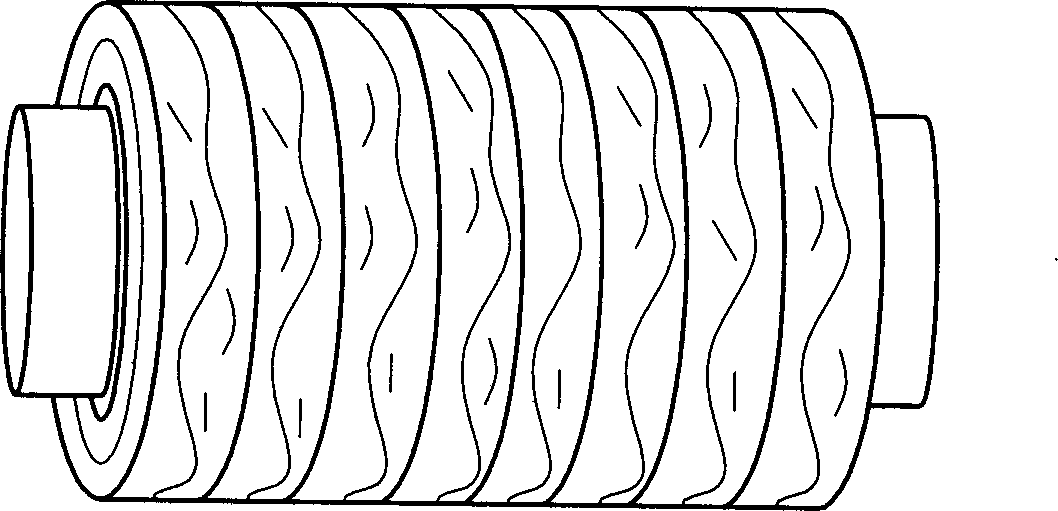

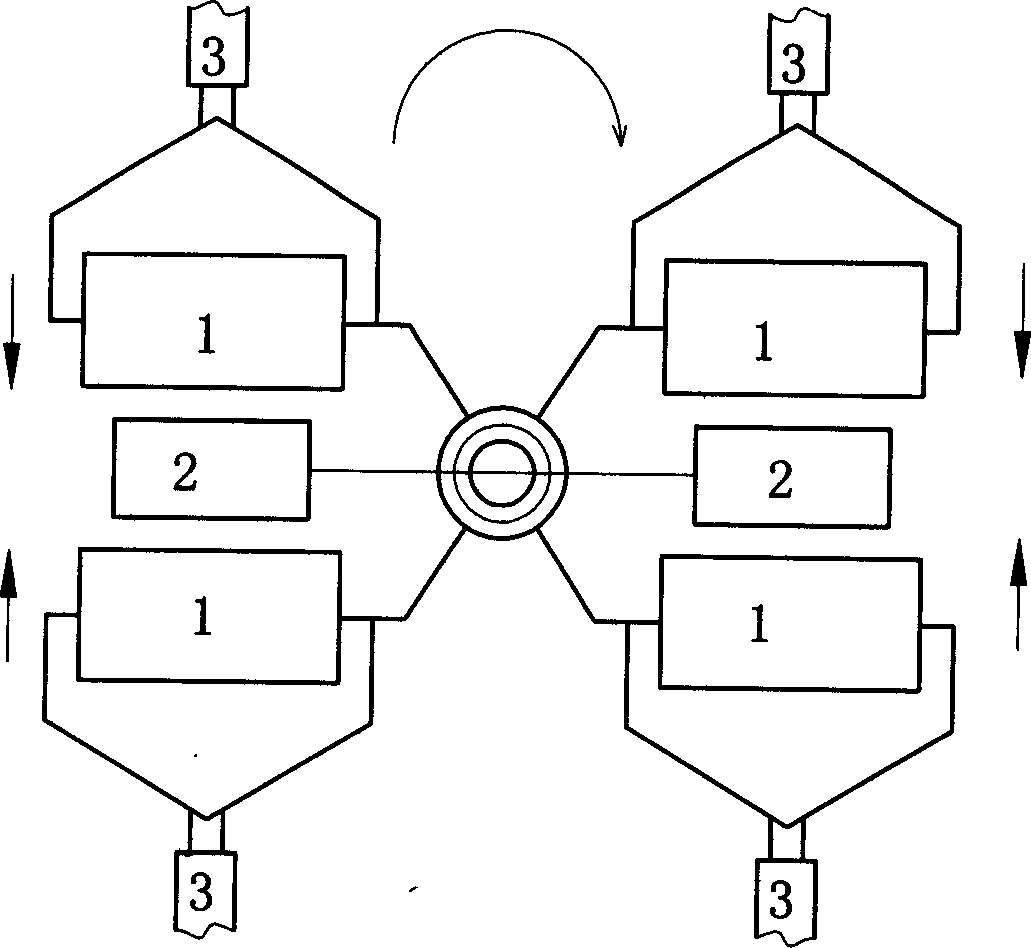

[0010] Attached below figure 1 ~ attached figure 2 , taking the rolling printing of three-dimensional wood grains on the aluminum profiles for construction as a specific illustration, and the specific implementation measures are as follows:

[0011] One, the technological process of this embodiment is briefly described as follows:

[0012] Metal workpieces to be treated (pre-treated)—spraying primer—primary pre-curing—spraying rendering color base powder—full brushing and leveling rendering color base powder—secondary preparatory curing—spraying cover powder—rolling Embossed texture - final curing - quality inspection - packaging

[0013] Two, the main technological process described in above-mentioned (1):

[0014] The surface of the metal workpiece will have defects such as unevenness or scratch marks, and the appearance of the workpiece or the appearance color after pretreatment is prone to uneven phenomena, so it is necessary to spray the base color powder coating on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com