On-line type polymer double-capillary extrusion rheometer

A polymer and capillary technology, applied in the field of polymer rheology testing, can solve the problems of extrusion products failing to meet quality requirements, time-consuming and labor-intensive, affecting the development of extrusion dies, etc., to achieve the effect of promoting further development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

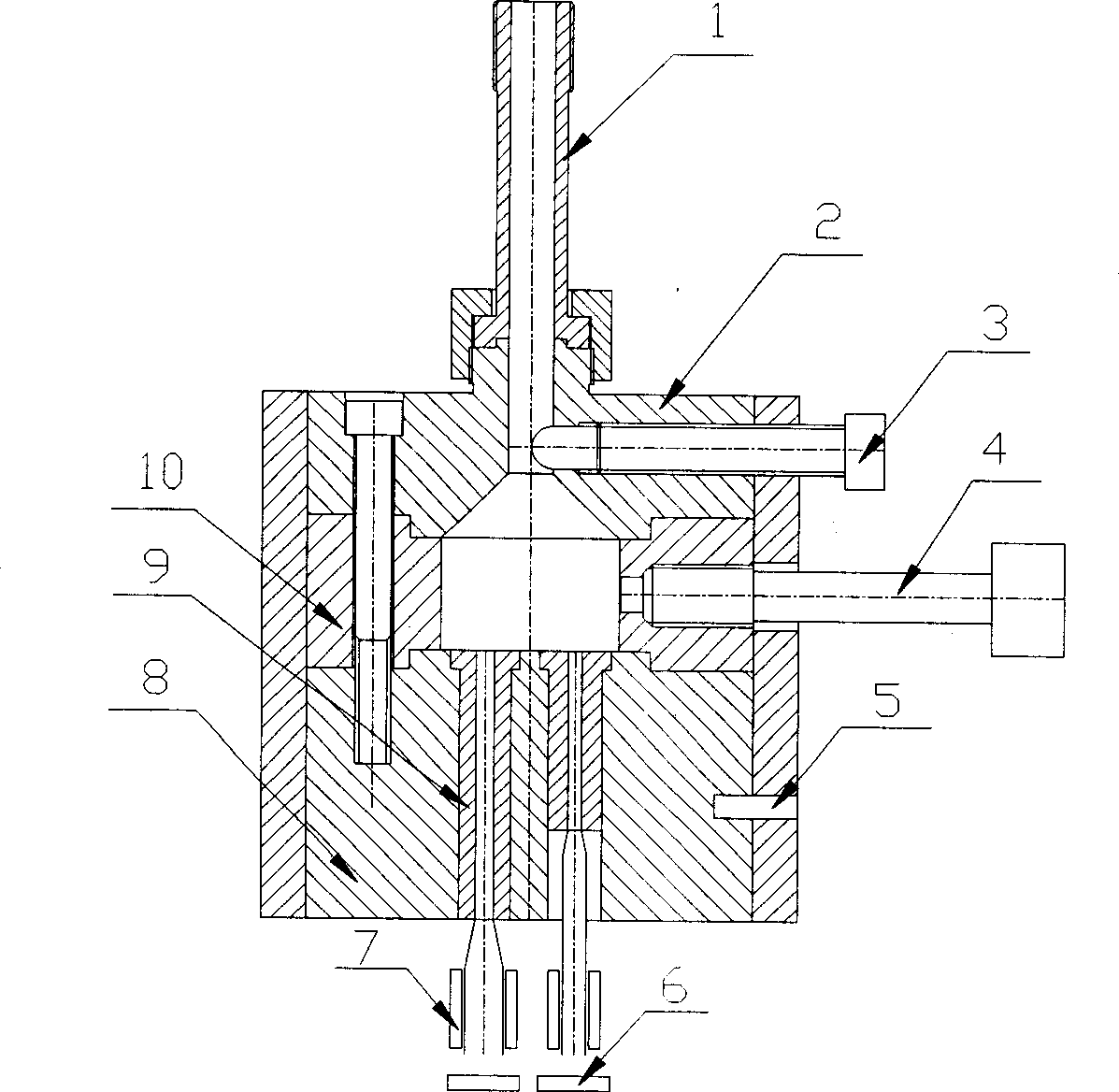

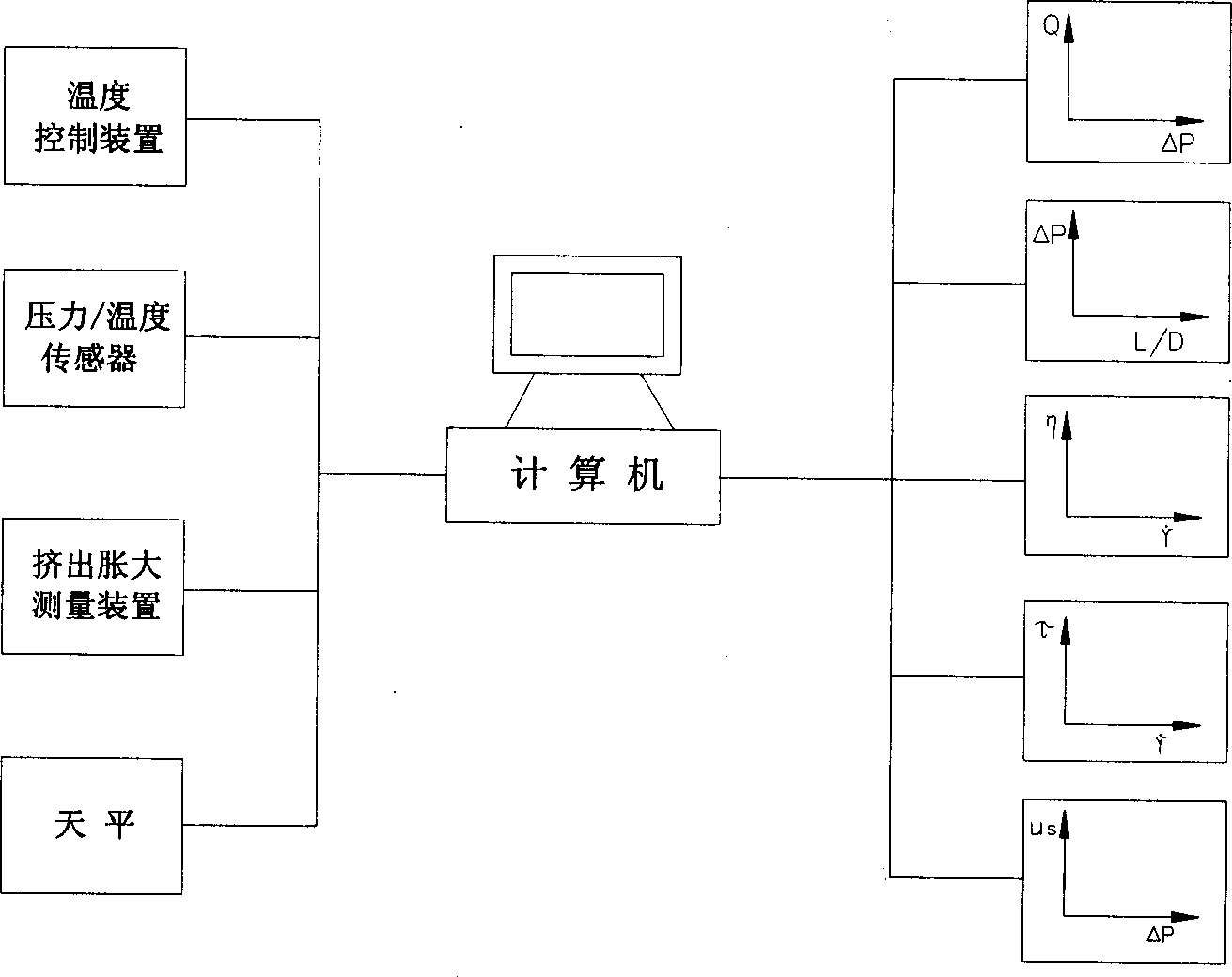

[0014] The following result technical scheme and accompanying drawing describe the best embodiment of the present invention in detail.

[0015] Measure the steady-state extrusion rheological characteristics and wall slip velocity of the polymer material PVC at a temperature of 200°C,

[0016] Embodiment steps are as follows:

[0017] Step 1. First block a capillary with a plug. Use a single capillary, install the rheometer on the flange between the extruder and the extrusion die, and adjust the temperature control device to control the temperature at the temperature required for measurement. within the scope;

[0018] Step 2. Start the extruder, set the extrusion process parameters according to the measurement needs, and perform PVC extrusion rheological measurement;

[0019] Step 3. Through the adjustment of the adjusting bolt, a group of capillaries with the same diameter and different length-to-diameter ratios are respectively used to measure the pressure drop under the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com