Paper-web changeable printer

A printer, variable technology, used in printing devices, printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, embodiments of a variable web printer to which the present invention is applied will be described with reference to the drawings.

[0034] (whole composition)

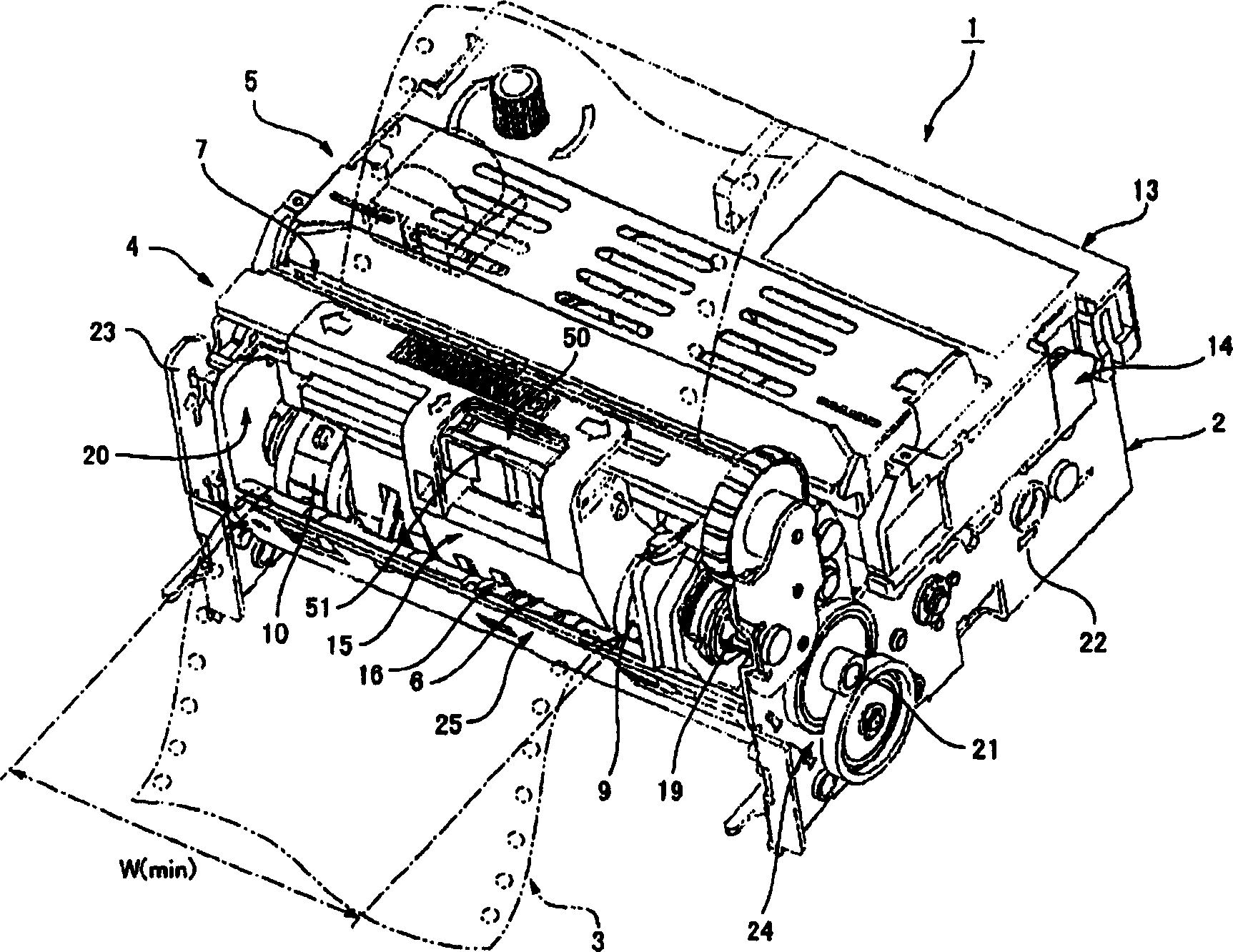

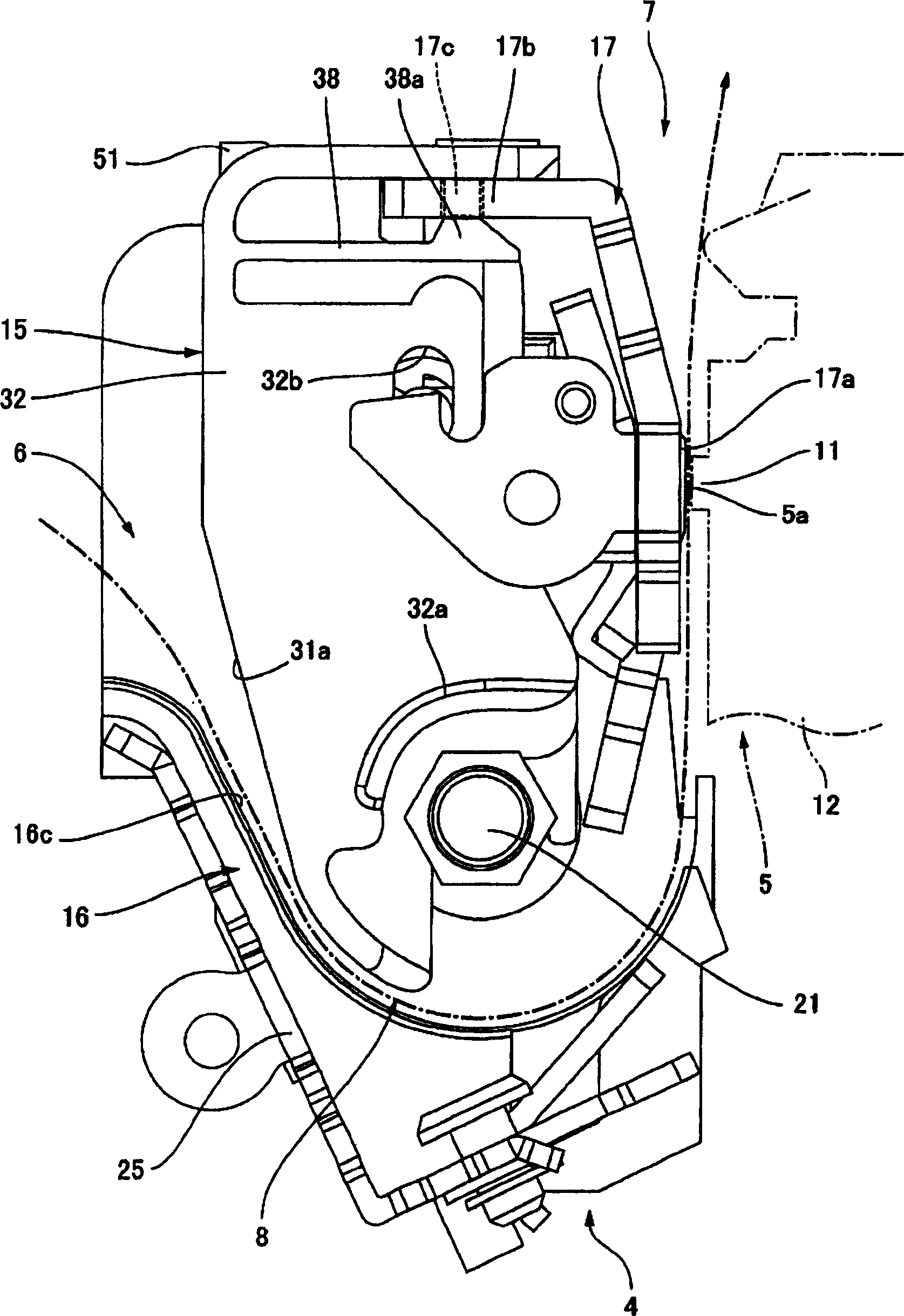

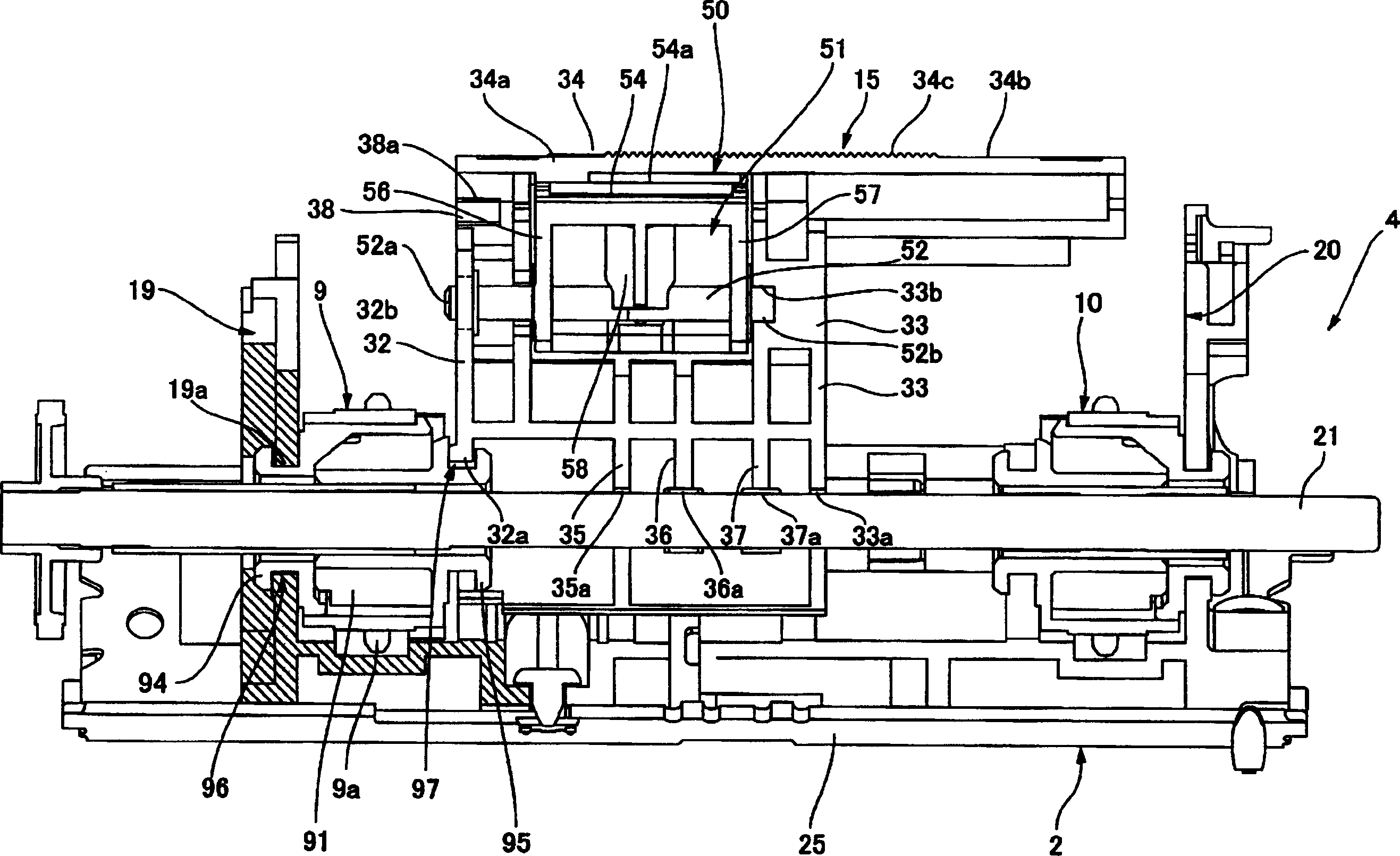

[0035] figure 1 is a perspective view showing the internal structure of the variable web printer according to this embodiment, figure 2 is an explanatory diagram showing a part of the transmission mechanism, image 3 It is a schematic cross-sectional view of the conveying mechanism partially cut by a vertical plane including the axis of the paper feed shaft, Figure 4 It is a partial rear perspective view in a state in which a part of the conveyance mechanism part is omitted.

[0036] Referring to these figures, the variable paper width printer 1 has a metal printer body frame 2, and a conveying mechanism 4 for conveying perforated paper 3 is assembled at the front end side of the printer body frame 2. The position on the side is assembled with a printing mechanism 5 for printing on the conveye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com