Driving device for terry motion members in cloth-shifting-type pile-loop loom

A driving device and cloth moving technology, applied in flannel looms, looms, textiles, etc., can solve the problems of warp damage, wrong cutting of looms, operator injury, etc., and achieve effective effects and prevent warp damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

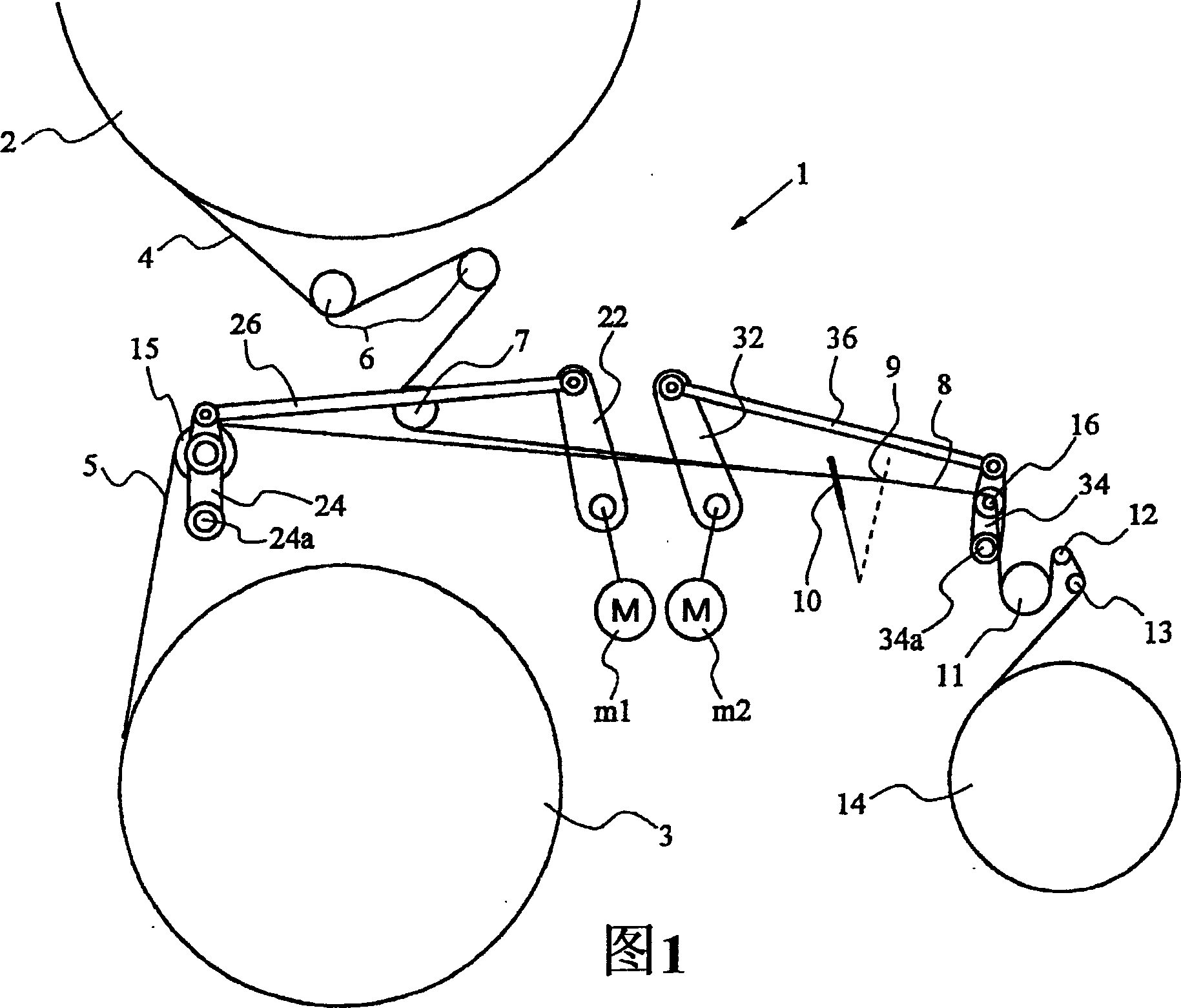

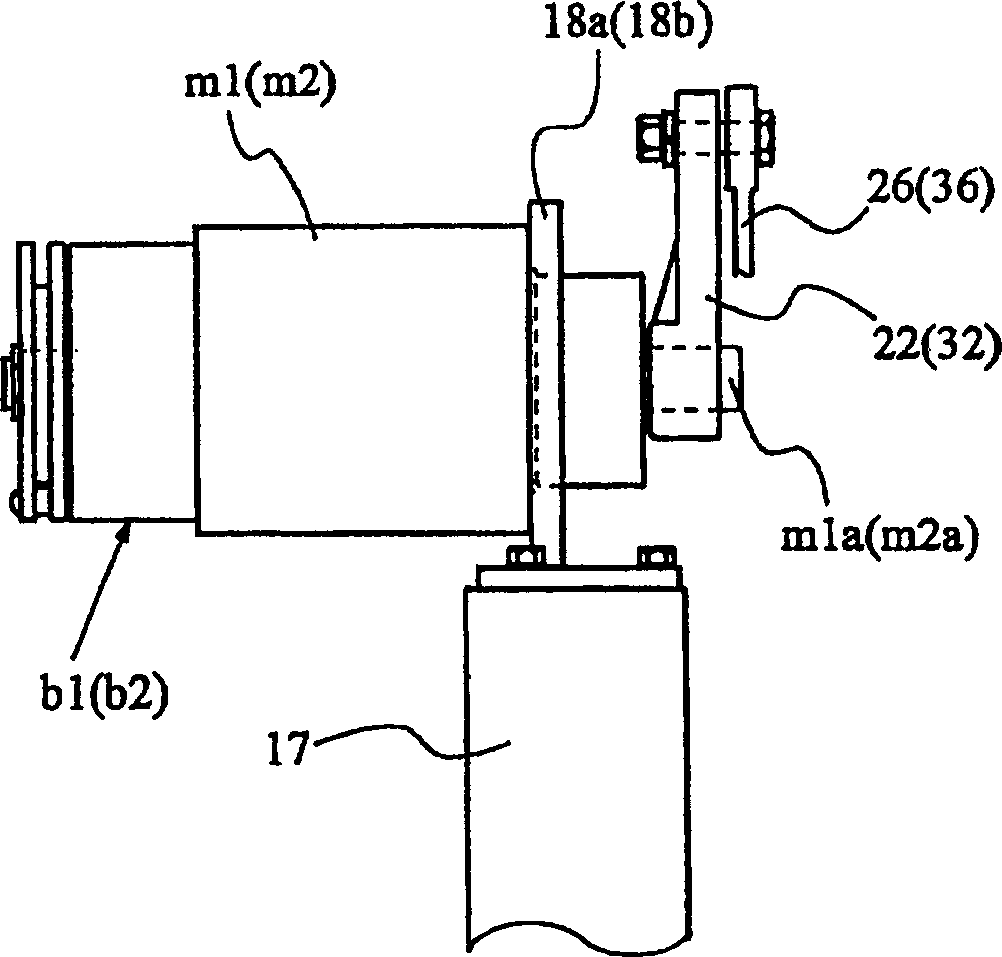

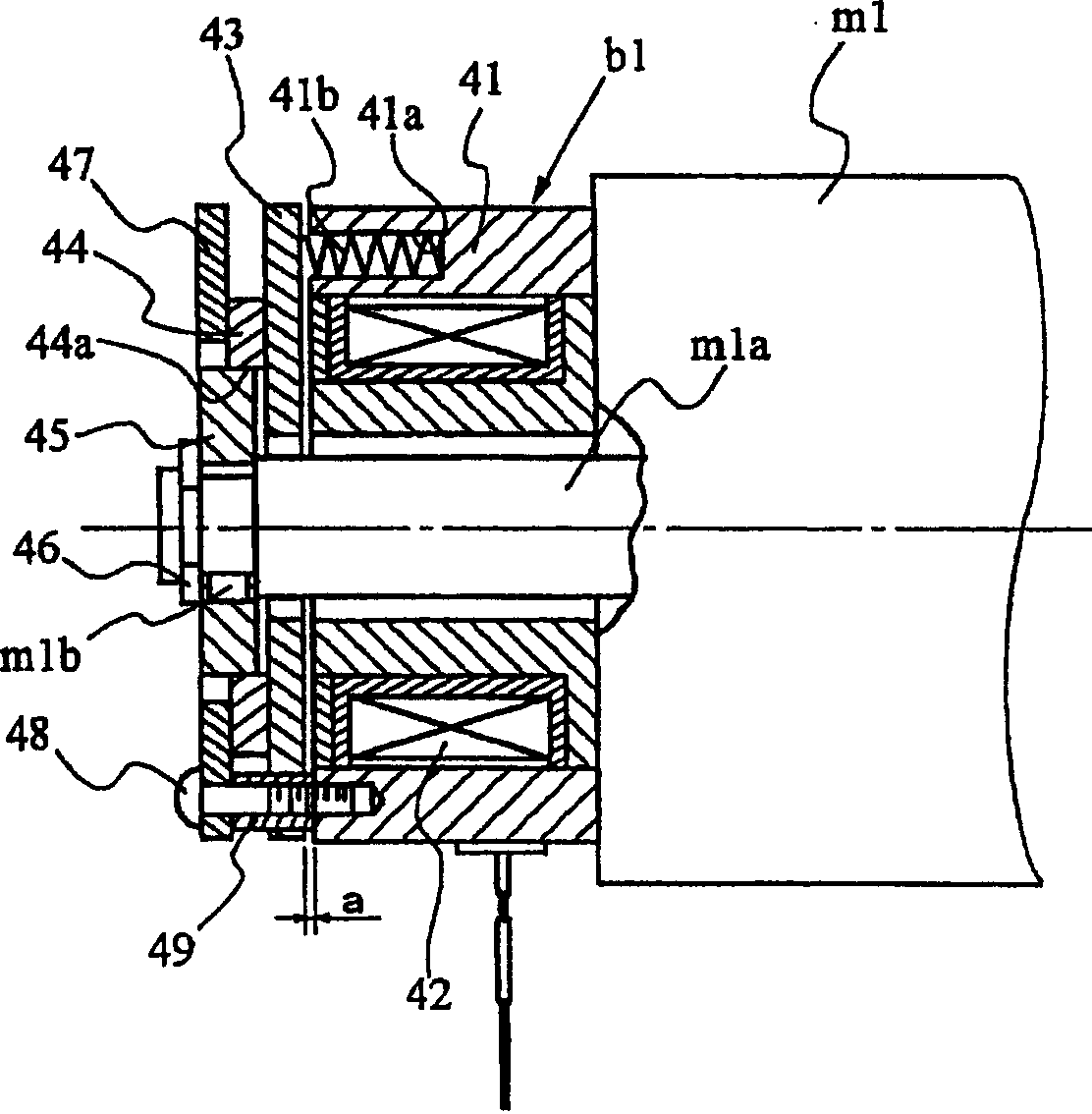

[0020] In Figure 1~ image 3 In one embodiment of the present invention shown, the illustrated terry loom 1 which is the object of the present invention is a cloth moving type terry loom that moves a cloth fell during the process of terry weaving to form piles.

[0021] Cloth mobile terry loom 1 has: warp beam 2 for terry warp yarns (upper side of the drawing), a plurality of terry warp yarns 4 rolled and pasted in sheet form; warp beam 3 for ground warp yarns (lower side of the drawing), A plurality of ground warp yarns 5 are pasted in a sheet form. The pile warp yarn 4 is sent out from the warp beam 2, is wound around two guide rollers 6, 6 and the outer periphery of the pile warp yarn tension roller 7 arranged on the downstream side thereof, is guided, and then passes through a heald (not shown) and The reed 10 is guided to the cloth fell 9 of the cloth 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com