Resonant point regulating circuit

A technology for adjusting circuits and resonance points, which is applied in the field of wireless power transmission, can solve problems such as difficulty in obtaining the best resonance point, unsuitability for mass production, and difficulty in implementation, so as to achieve self-adaptive adjustment, optimization of resonance quality, and improved charging The effect of potency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

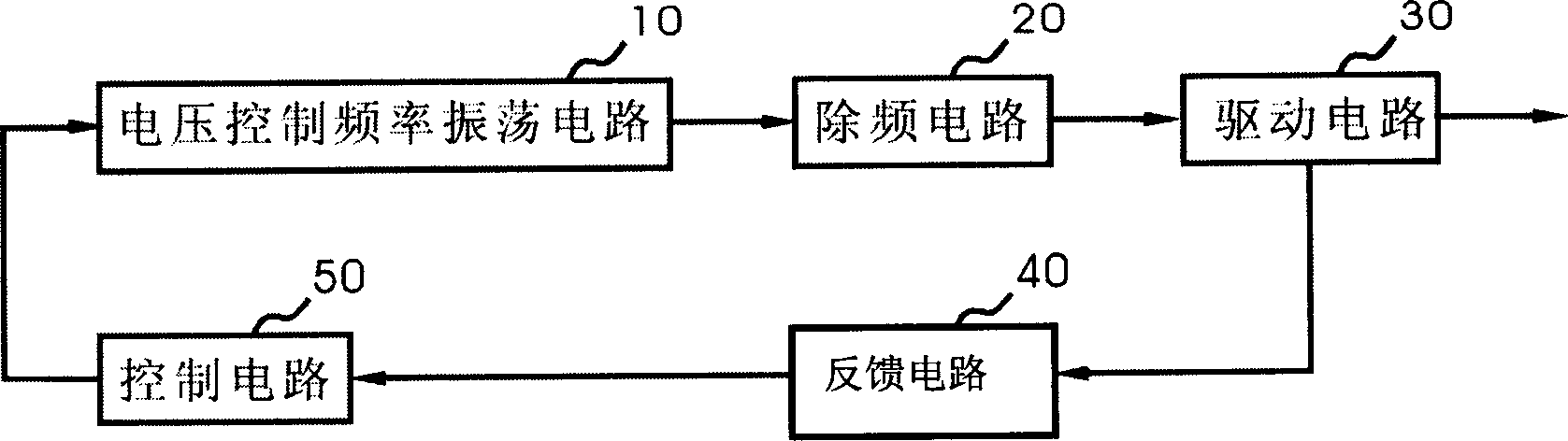

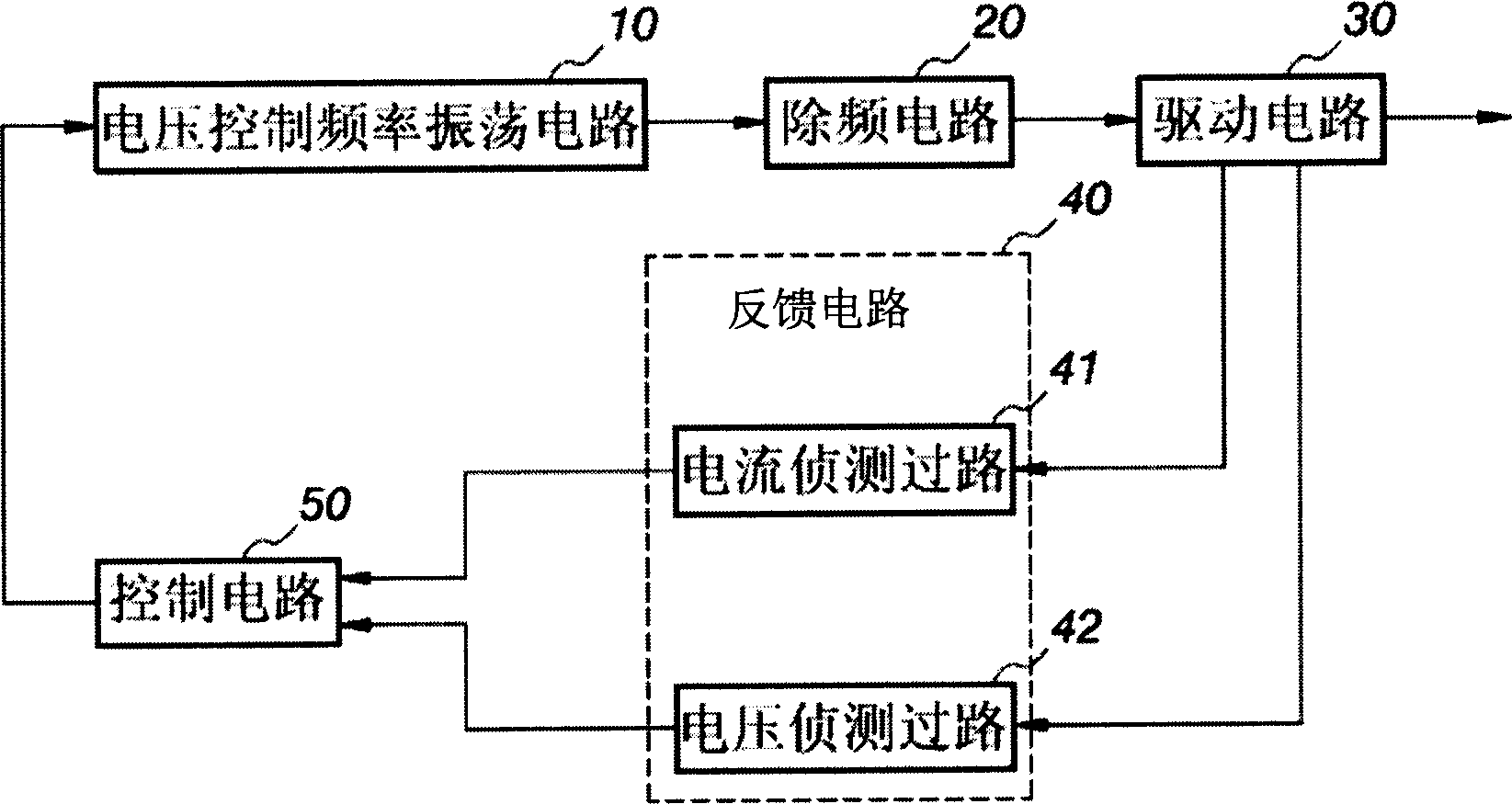

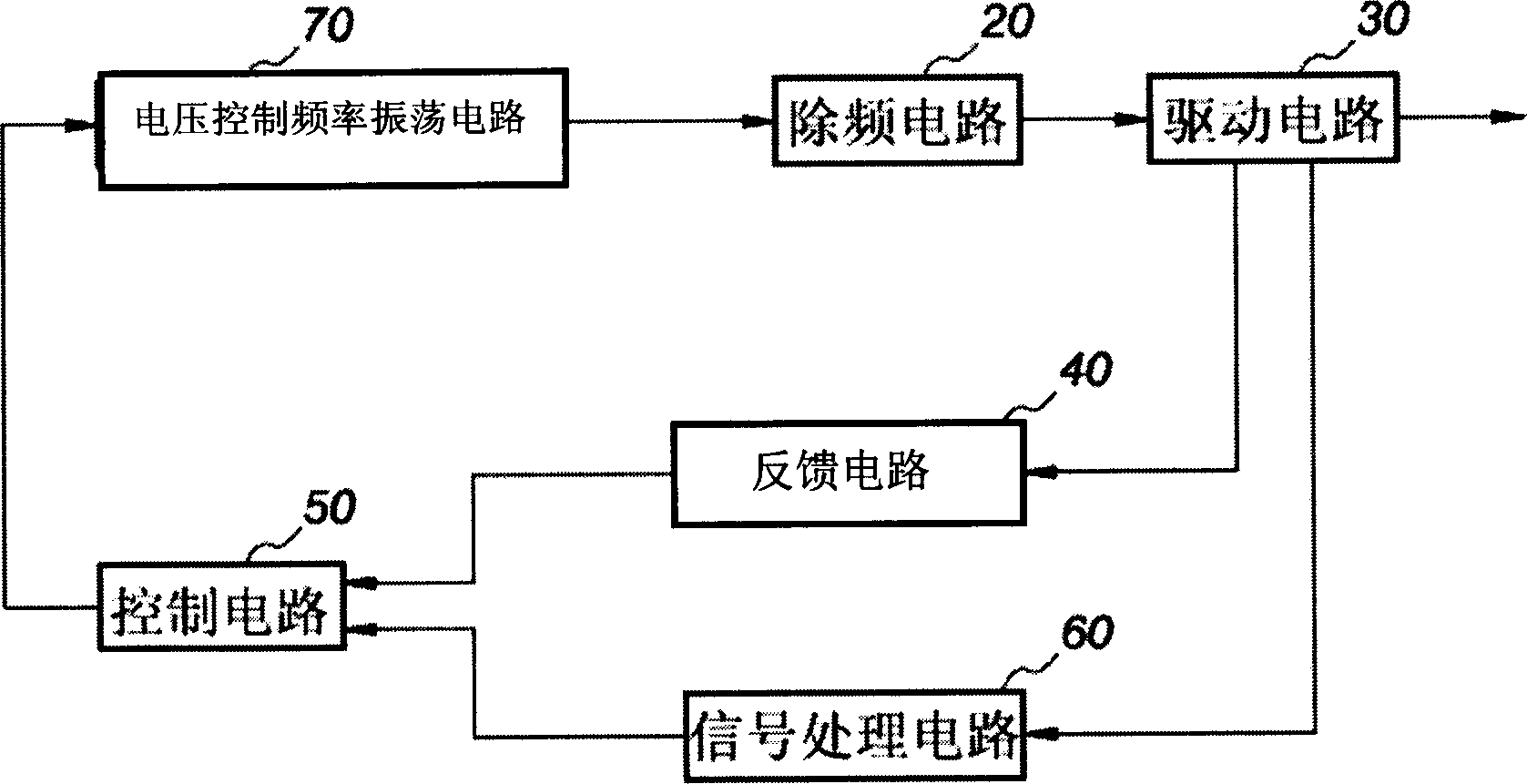

[0020] see figure 1 , the resonance point adjustment circuit of the present invention includes: a voltage-controlled frequency oscillation circuit 10, a filter circuit 20, a drive circuit 30, a feedback circuit 40 and a control circuit 50, when the voltage-controlled frequency oscillation circuit 10 is generated by the filter circuit 20 When the oscillation frequency is output by the drive circuit 30, the feedback circuit 40 can feed back the output frequency of the drive circuit 30 to the control circuit 50, and after the control circuit 50 obtains the best resonance point, then control the output of the oscillation frequency of the voltage control frequency oscillation circuit 10 , so that the resonance quality can be optimized to improve performance. When the drive circuit 30 outputs the oscillation frequency, the oscillation frequency is fed back to the control circuit 50 through the feedback circuit 40, so that the control circuit 50 analyzes and obtains the optimum reson...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com