Fixed glass moulded shaper for simplifying core-takeout operation

A fixed, glass technology, used in glass forming, glass manufacturing equipment, glass pressing, etc., can solve the problems of poor alignment, long turning time, long time consumption, etc., to improve the eccentricity problem and shorten the search time. , The effect of simplifying the core taking operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] For convenience of description, in the following embodiments, the same components are denoted by the same reference numerals.

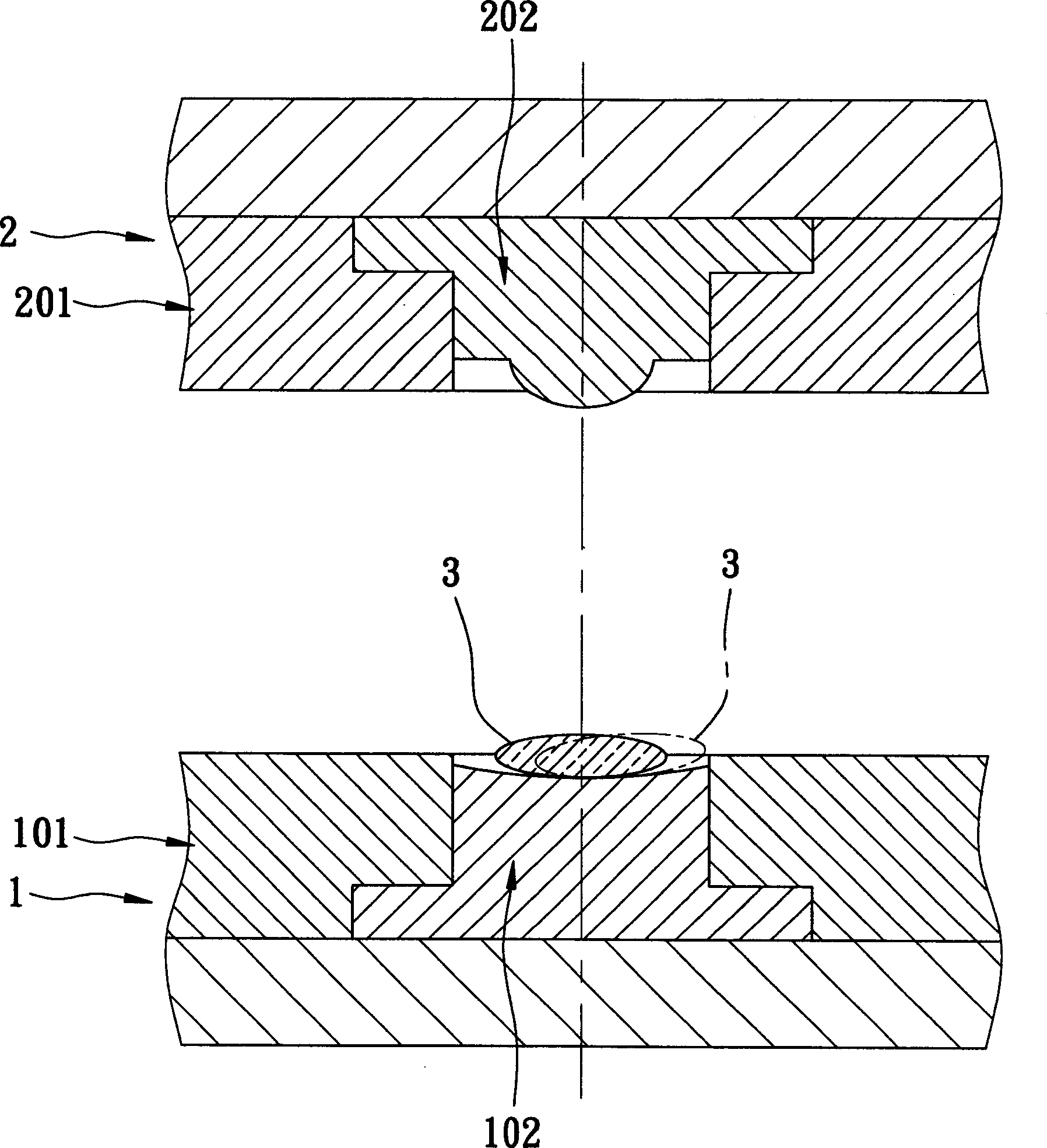

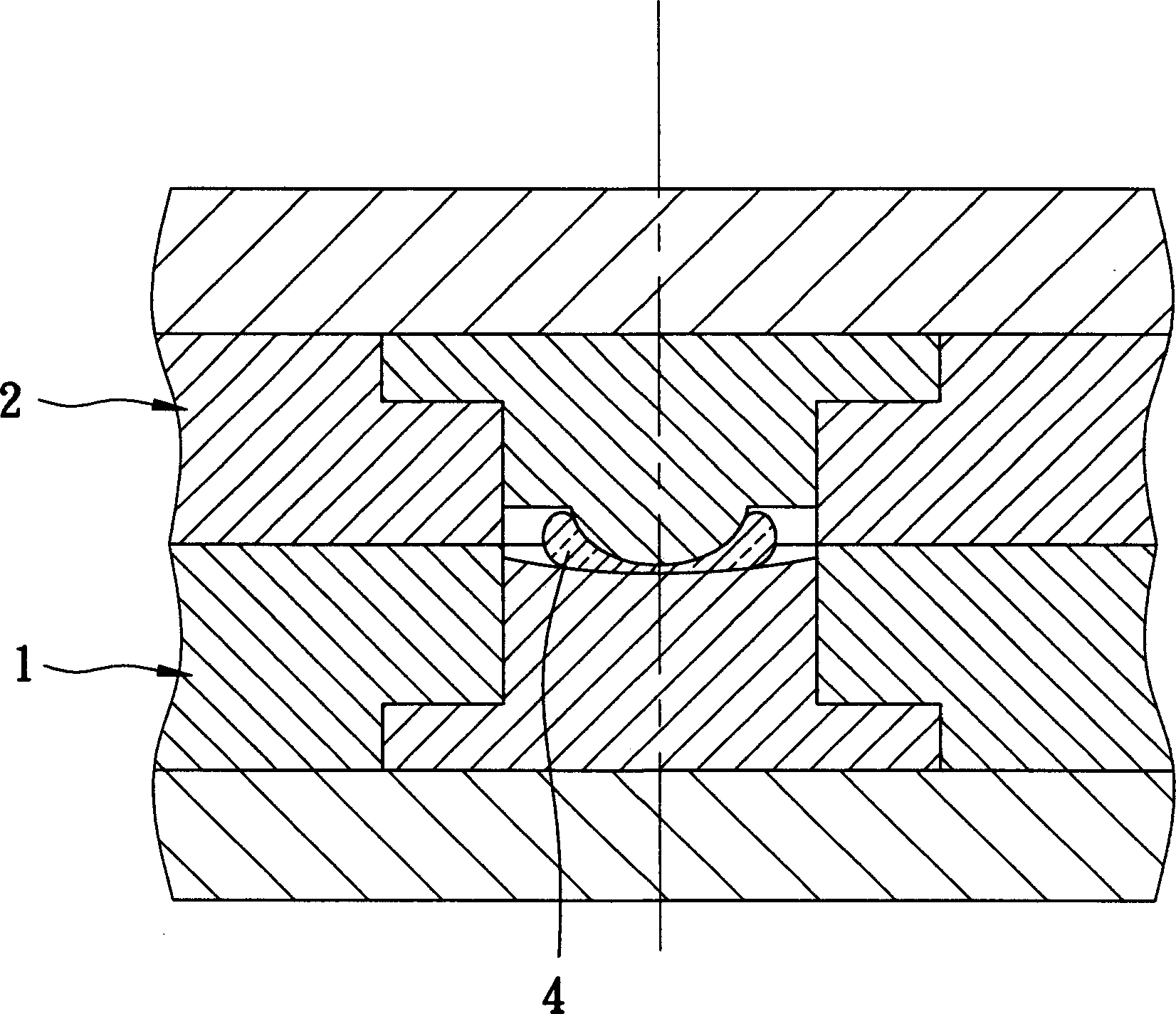

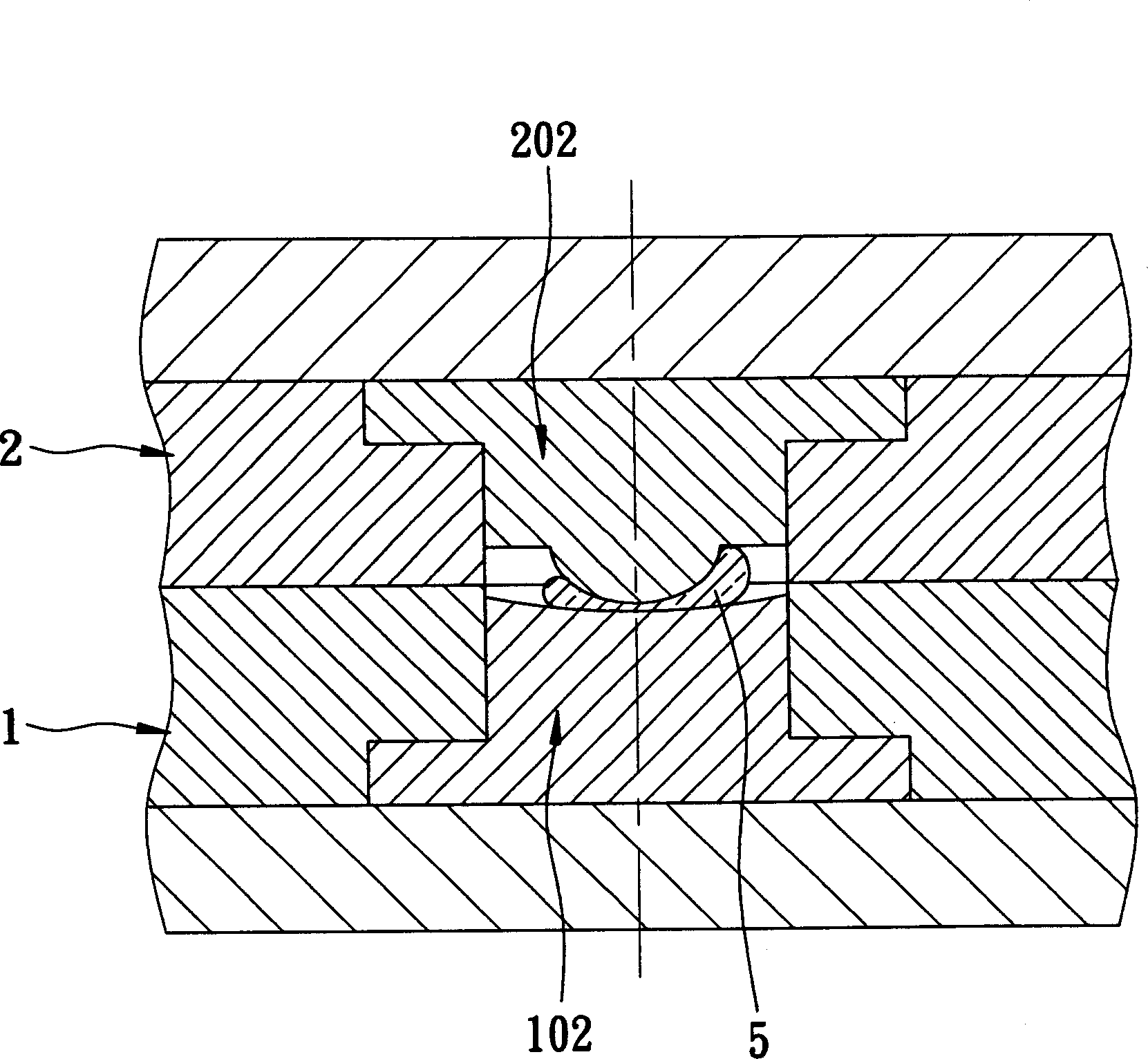

[0018] Such as Figure 5 and Figure 7 As shown, the first preferred embodiment of the fixed glass molding device of the present invention that can simplify the core-taking operation can be used to heat and press a glass material 100 to form a glass lens 200, and the forming device includes A lower mold unit 10 , a set of shape-limiting cylinder 20 set in the lower mold unit 10 and an upper mold unit 30 opposite to the lower mold unit 10 .

[0019] The lower mold unit 10 has a lower mold base 11 , and a lower mold core 12 installed inside the lower mold base 11 along an axis L. The lower mold base 11 has a lower mold plate 13 and a lower mold plate 14 which are superimposed and locked in the axial direction. The mating surface 142 and a lower seating hole 143 extending from the end surface 141 to the lower mating surface 142 is in the shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com