Negative active material for non-aqueous electrolyte battery,method of preparing same and non-aqueous electrolyte battery

A technology of negative electrode active material and non-aqueous electrolyte, applied in the field of preparing the negative electrode active material and lithium secondary battery, can solve the problem that the use of amorphous tin oxide cannot be well accepted and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

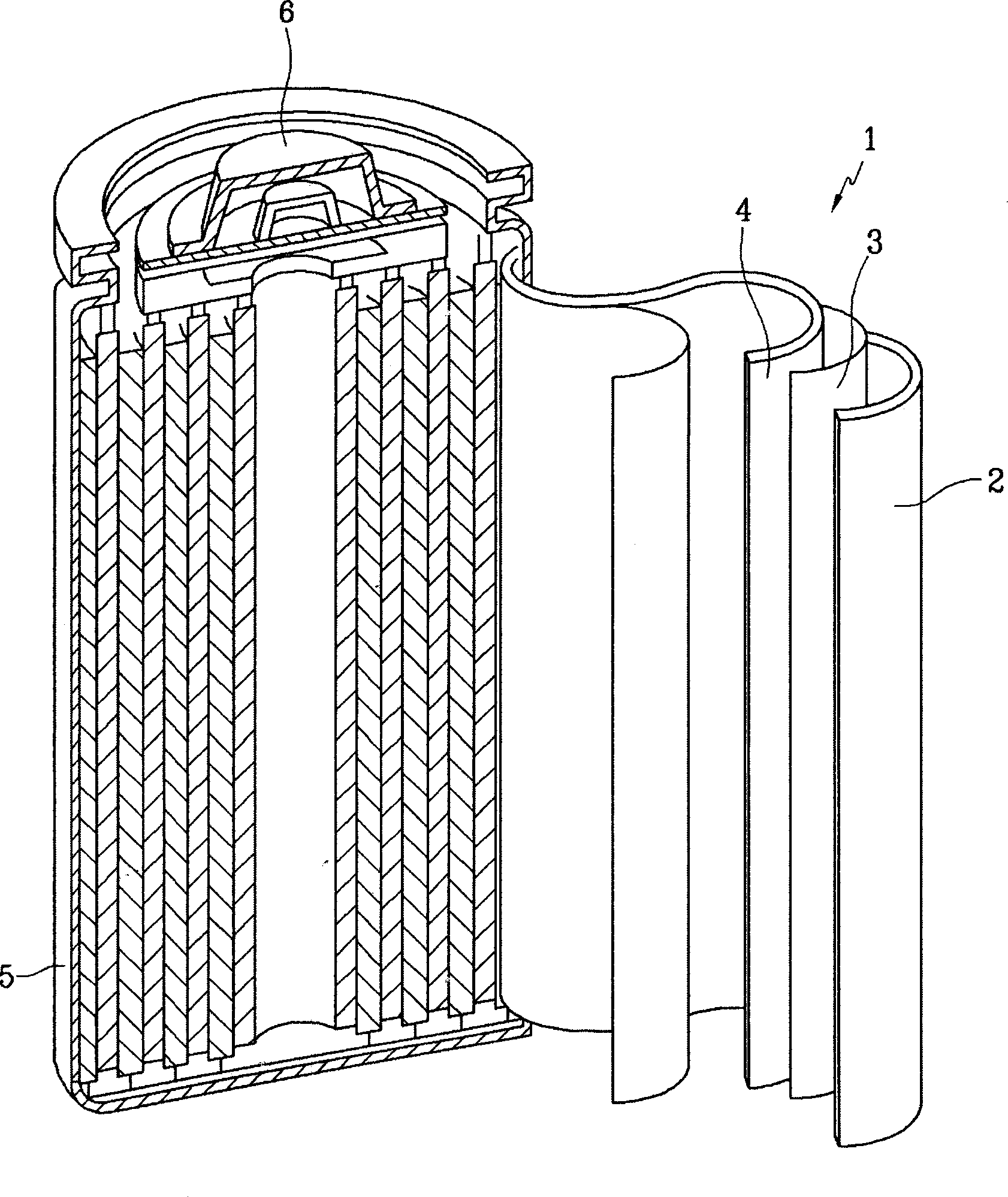

[0042] A method for producing the negative electrode active material of the present invention is now described. First, a vanadium-containing source, a lithium-containing source, and a metal-containing source are mixed in a solid phase. Adjust the mixing ratio of vanadium-containing source, lithium-containing source and metal-containing source to an appropriate range.

[0043] Vanadium-containing sources can be one or more of the following substances: vanadium metal, VO, V 2 o 3 , V 2 o 4 , V 2 o 5 , V 4 o 7 、VOSO 4 ·nH 2 O, NH 4 VO 3 Wait.

[0044] The lithium-containing source may be one or more of lithium carbonate, lithium hydroxide, lithium nitrate and lithium acetate.

[0045] The metal-containing source may be one or more of an oxide or hydroxide comprising at least one of the following metals: Al, Cr, Mo, Ti, W, and Zr. Examples of metal containing sources include, but are not limited to Al(OH) 3 、Al 2 o 3 、Cr 2 o 3 、MoO 3 、TiO 2 、WO 2 or ZrO 2 . ...

Embodiment 1

[0072] Li in the solid phase 2 CO 3 , V 2 o 3 and TiO 2 Mixing was performed at a Li:V:Ti molar ratio of 1.1:0.89:0.01. The mixture was heat-treated at a temperature of 1100 °C under a nitrogen atmosphere to prepare the negative active material, Li 1.1 V 0.89 Ti 0.01 o 2 . The as-prepared negative active material exhibits the R-3M crystalline structure in the single-phase diffraction pattern.

[0073] 80 wt% of the prepared negative active material, 10 wt% graphite conductive agent and 10 wt% polyvinylidene fluoride (PVDF) binder were mixed in N-methylpyrrolidone (NMP) to prepare negative active material slurry. This slurry was coated on a copper current collector to fabricate a negative electrode. The resulting active material had a density of 2.4 grams per cubic centimeter (g / cc). The active material is a mixture of active material, conductive agent and binder formed on the current collector.

[0074] The negative electrode showed a high initial reversible capaci...

Embodiment 2

[0076] Adopt the same method as in Example 1 to prepare the negative electrode active material and negative electrode, the difference is that the molar ratio of Li: V: Ti is changed to 1.1: 0.87: 0.03 to prepare the negative electrode active material, Li 1.1 V 0.87 Ti 0.03 o 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com