Auto-aligning touch system and method

A touch screen, touch surface technology, applied in the field of automatic calibration of touch systems, automatic calibration of touch systems, can solve problems such as inconvenience and trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

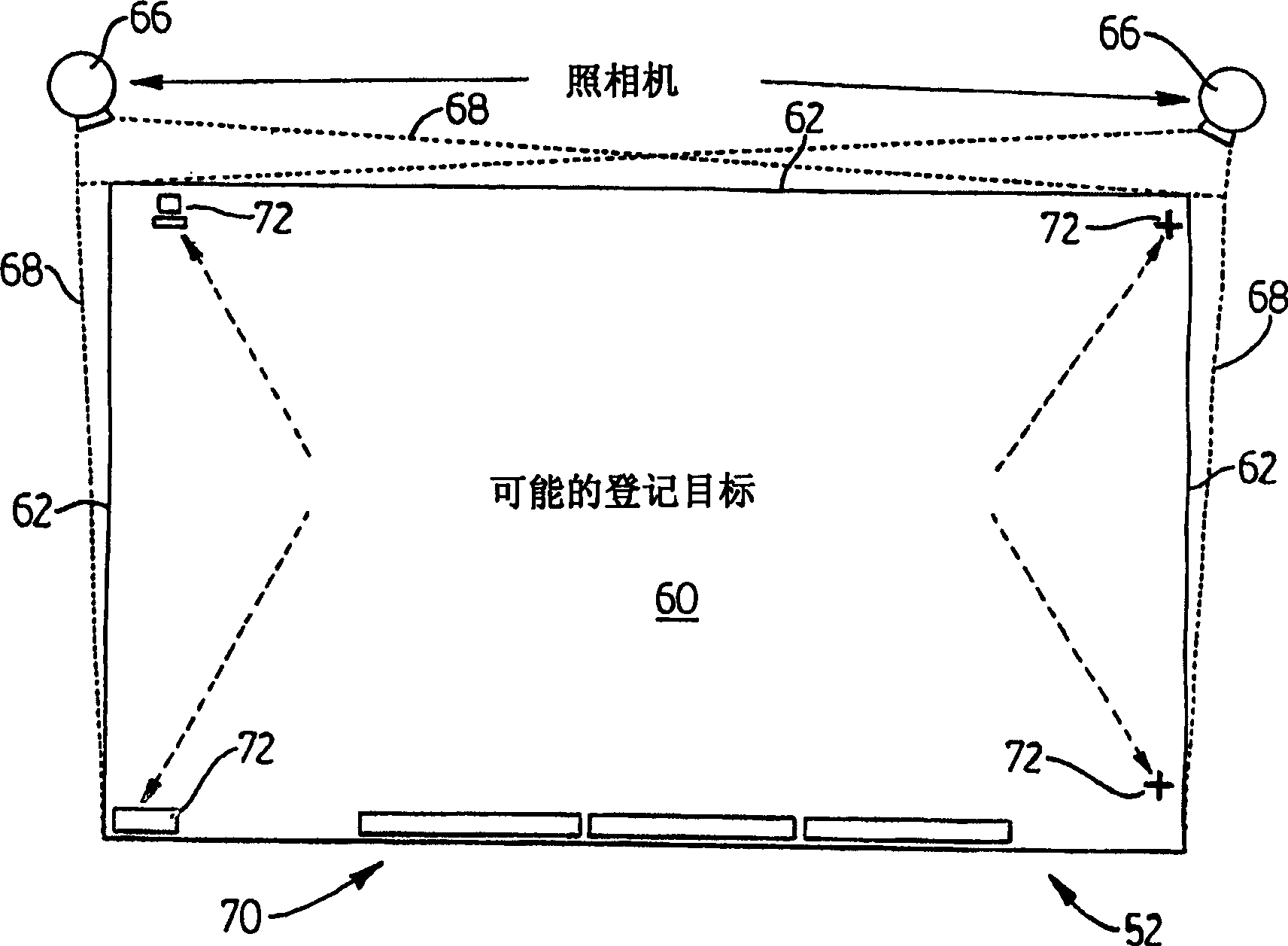

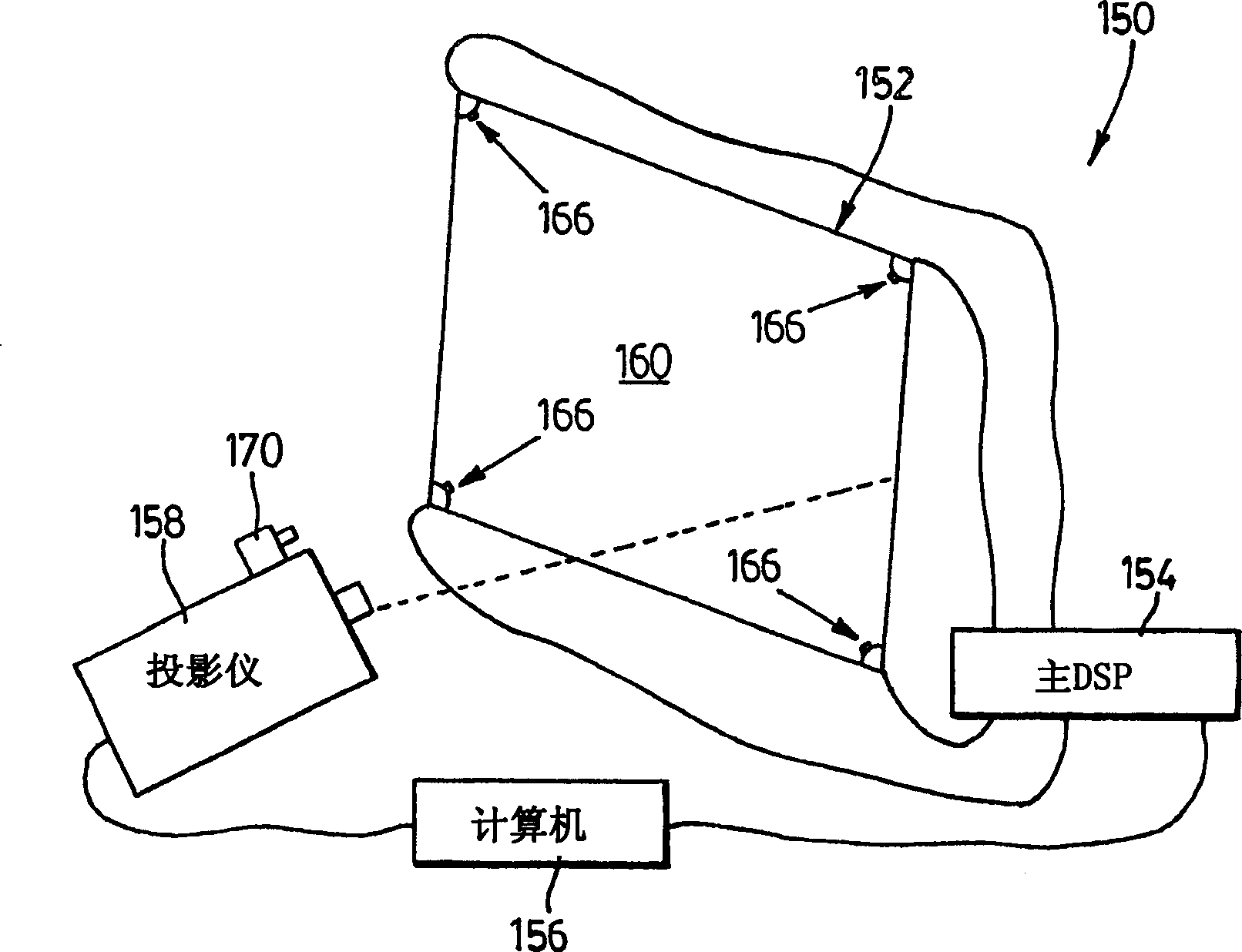

[0036] The present invention generally relates to a touch system and method. The system and method use the acquired image of the touch surface to automatically calibrate the touch system by mapping the touch screen coordinate system to the display coordinate system, and the touch surface has at least one known Reference mark image. In this way, the touch system can be calibrated in real time when a stylus touch is made on the touch surface of the touch screen, thus maintaining high resolution and avoiding the need to perform calibration routines that require manual intervention. The present invention is basically applicable to any application for calibrating the display image of the touch surface, such as electronic whiteboards, touch liquid crystal display (LCD) screens, personal digital assistants (PDA), and portable touch systems. The preferred embodiments of the present invention will be described below.

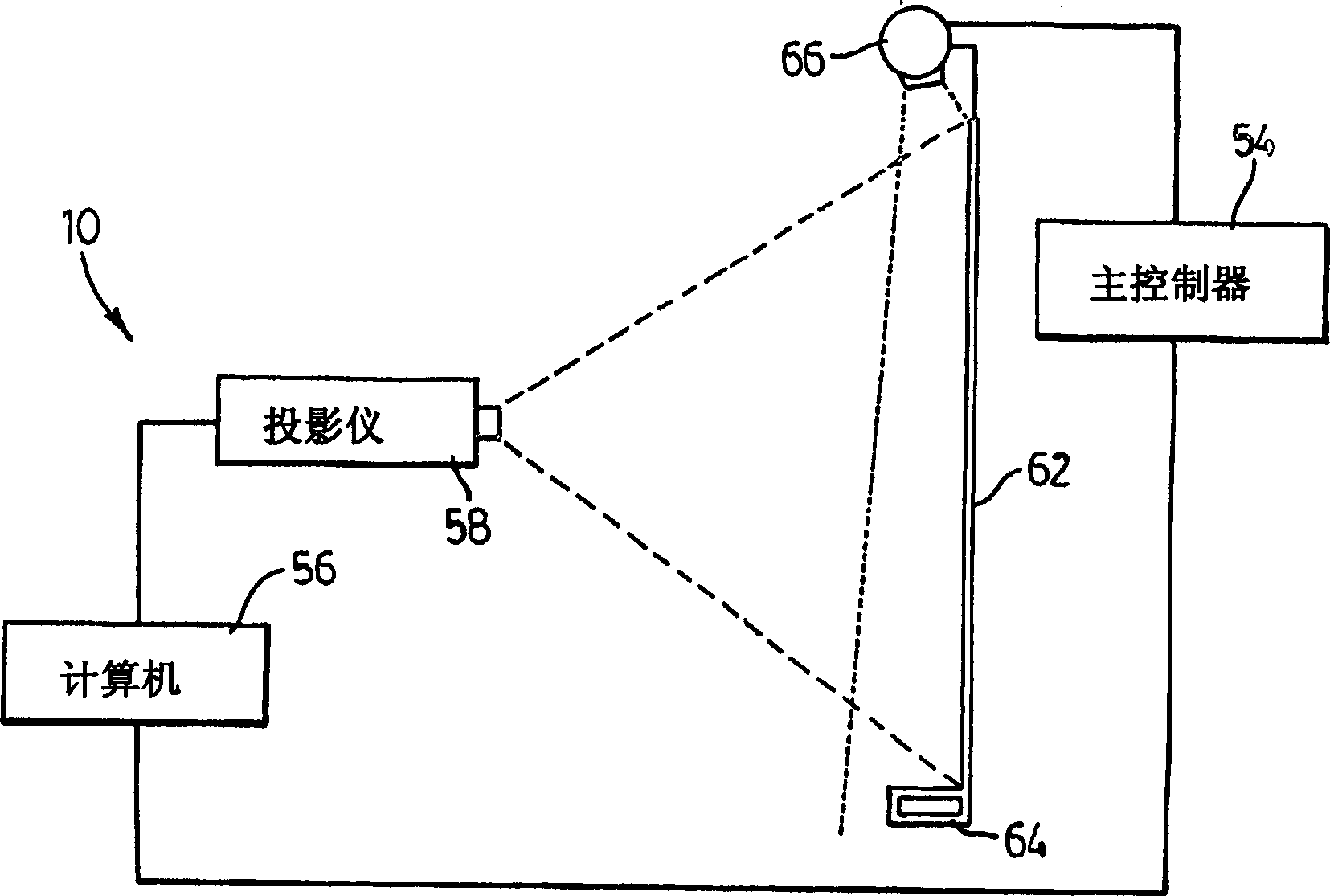

[0037] See figure 1 with figure 2 , Which shows a camera-based touch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com