Air extraction cylinder

A technology of pumping cylinders and pumping holes, which is applied in the direction of pressurization/vaporization packaging, etc., can solve the problems of reducing the efficiency of vacuuming, increasing the number of pumping times, and poor vacuuming effects, etc., and achieves simple structure and large pumping capacity , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is further described in detail below in conjunction with the accompanying drawings and specific embodiments:

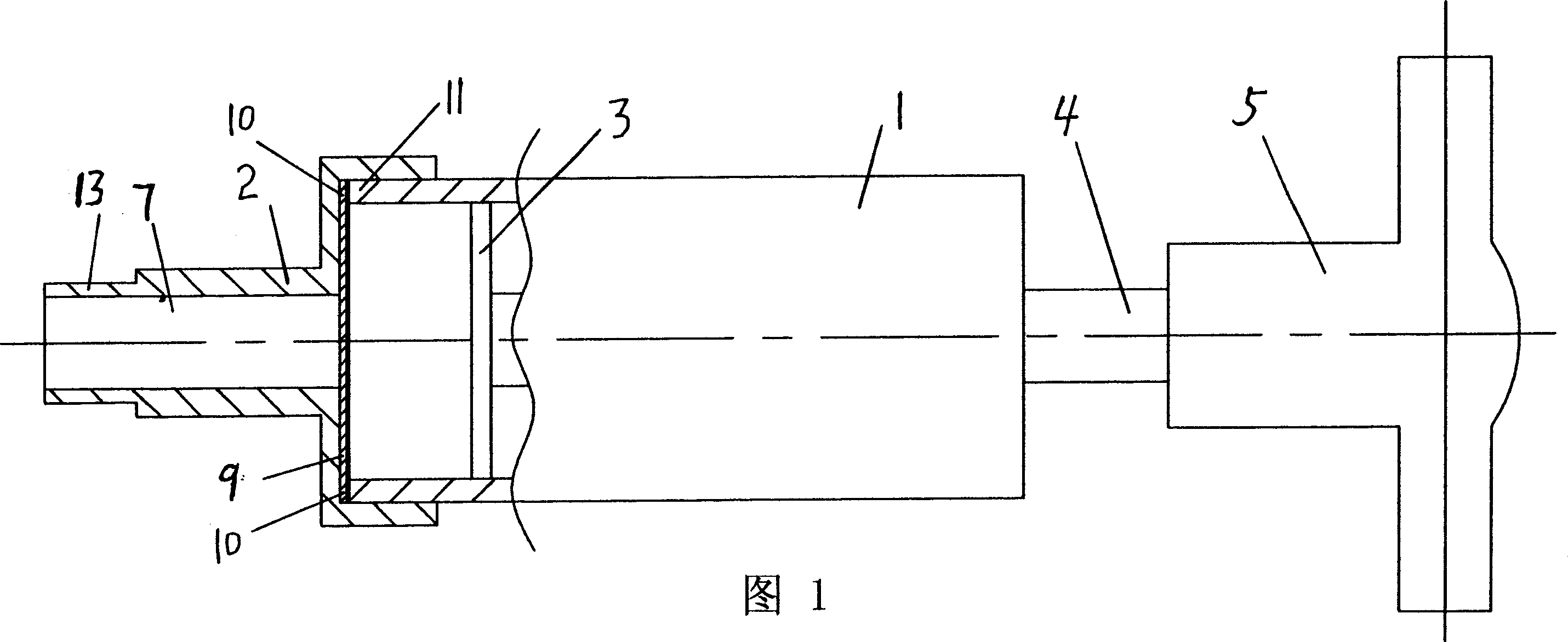

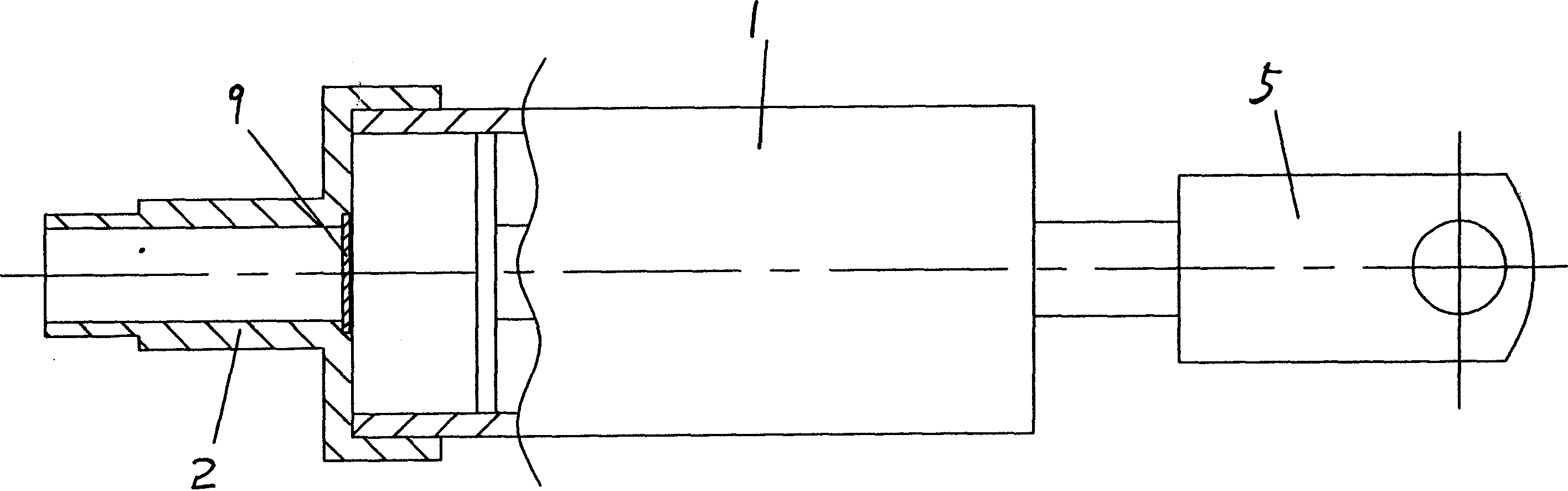

[0014] The present invention includes a sleeve 1 and a nozzle 2 sleeved on the sleeve 1, a piston 3 is installed in the sleeve 1, the piston 3 is connected with the handle 5 through a pull rod 4, and the sleeve is pulled on the handle 5 by hand. The piston 3 in the cylinder 1 is used to pump air.

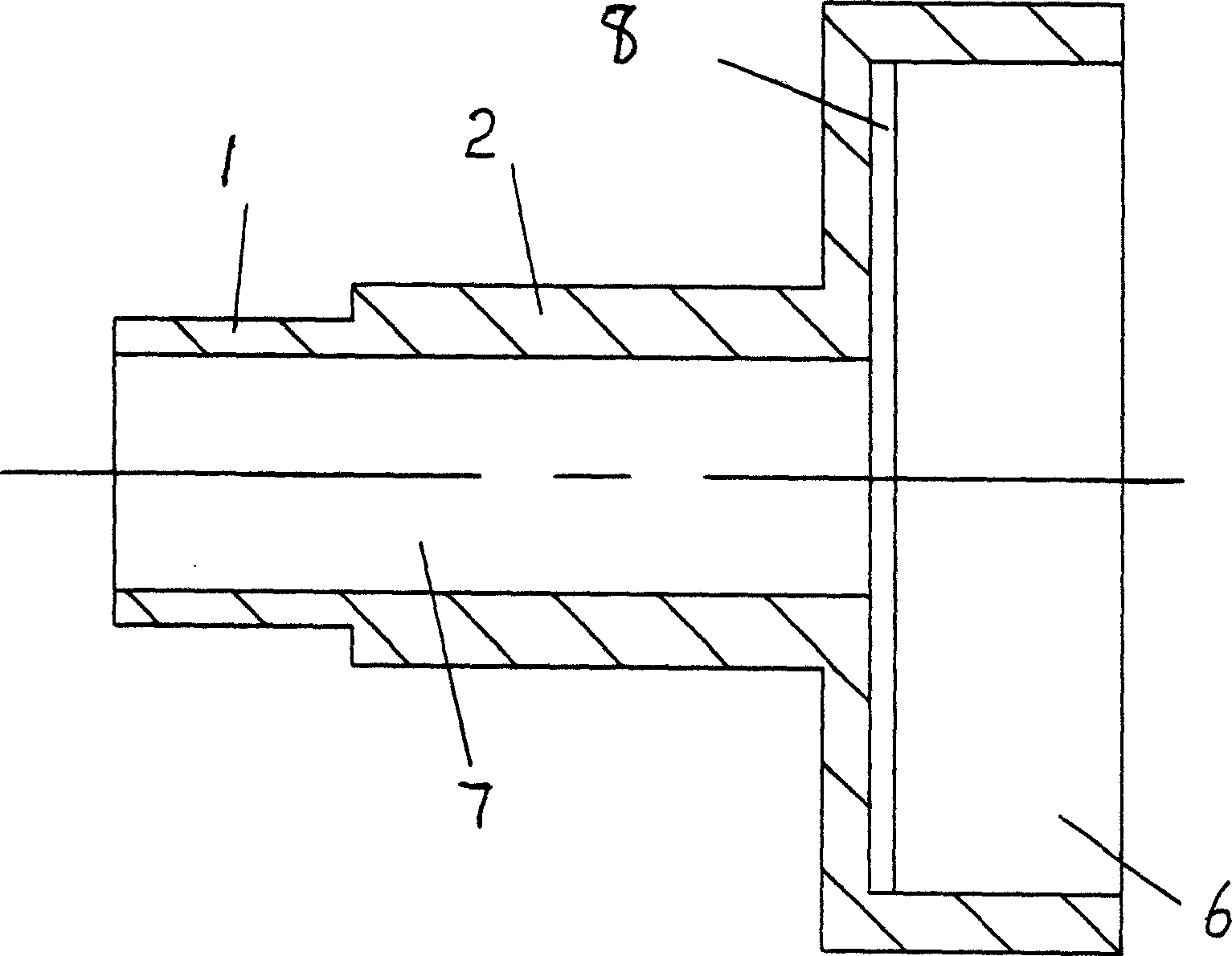

[0015] The sleeve 1 is a hollow cavity, one end of which is pressed into the cavity 6 of the barrel mouth 2, the pull rod 4 is inserted from the other end of the sleeve 1 and connected with the piston 3 in the sleeve 1, and the other end of the pull rod 4 is connected with the piston 3 in the sleeve 1. The handle 5 is connected with the fixed. There is an air extraction hole 7 on the barrel mouth 2. In order to better extract the air in the package such as the vacuum bag, a groove 8 is opened above the air extraction hole 7 at the end of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com