System comprising an accumulator upstream of a lost motion component in a valve bridge

An accumulator, lost motion technology, applied in the direction of engine components, valve devices, machines/engines, etc., can solve the problems of high valve train load, short refill time, performance loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

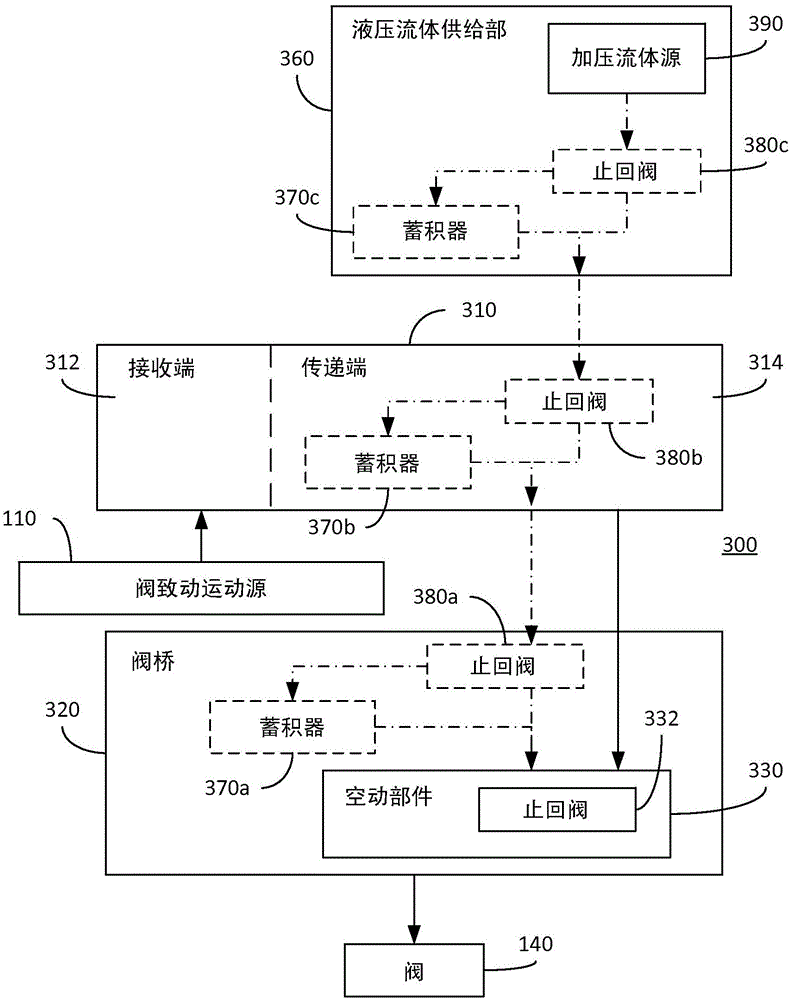

[0028] Now refer to image 3 , which shows a valve actuation system 300 according to the invention. As shown, system 300 includes valve actuation motion source 110 described above operatively connected to motion receiving end 312 of rocker arm 310 . The rocker arm 310 also includes a motion transfer end 314 . A hydraulic fluid supply 360 is in fluid communication with the rocker arm 310 . System 300 also includes a valve bridge 320 operably connected to two or more engine valves 140 . The valve bridge 320 may include a lost motion component 330 as is known in the art of bridge braking systems.

[0029] Although image 3 Not shown in , but rocker arm 310 is typically supported by a rocker shaft, and rocker arm 310 reciprocates about the rocker shaft. Also, the rocker shaft may contain elements of the hydraulic fluid supply 360 in the form of hydraulic fluid passages formed along the length of the rocker shaft, as is known in the art. The motion receiving end 312 may comprise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com