Refractory heat-preservation structure capable of improving service life of clarifying tube

A technology of refractory heat preservation and clarification tube, which is applied in the field of support and bottom refractory support structure, and can solve problems such as arsenic pollution, difficult glass clarification, and weak clarification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

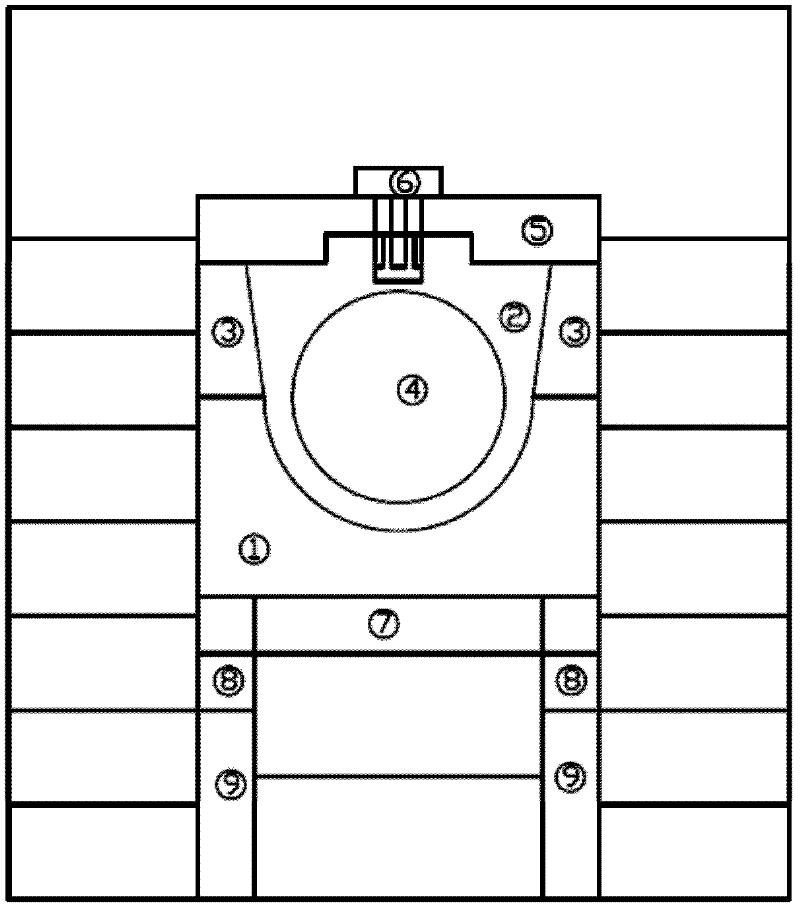

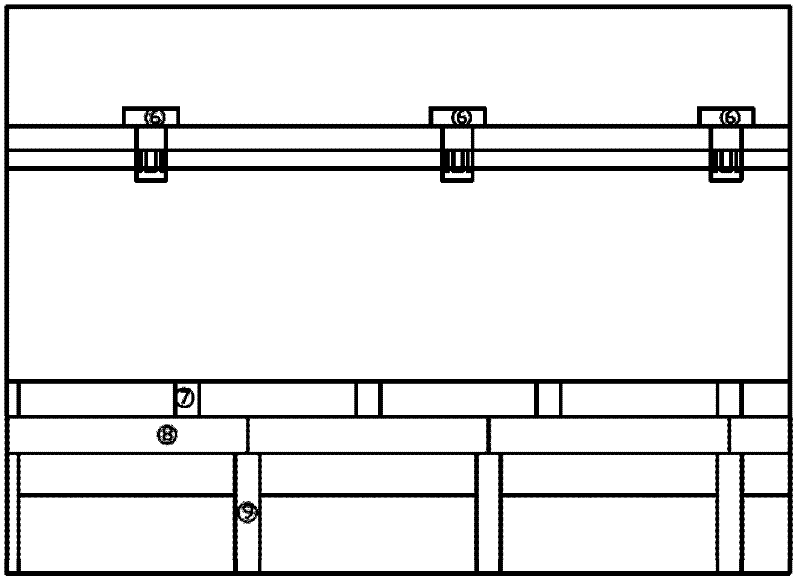

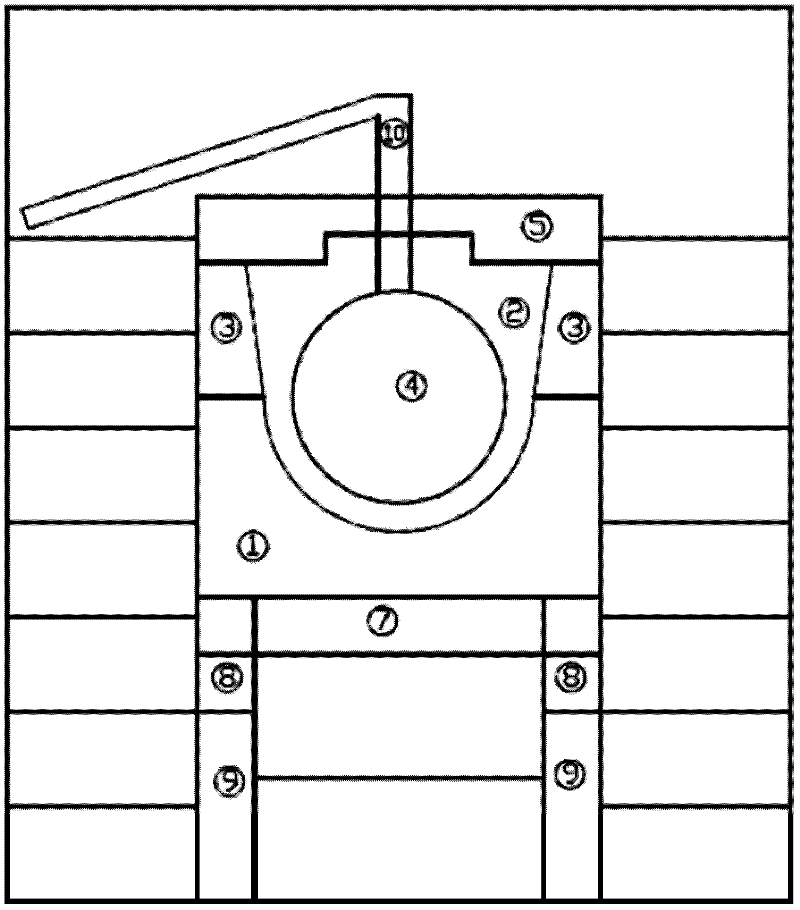

[0026] Such as figure 1 and image 3 As shown, the bottom support structure of a fire-resistant and heat-preserving structure for improving the service life of a clarification pipe of the present invention includes: bottom transverse support bricks 7, bottom longitudinal support bricks 8, and bottom vertical support bricks 9. The bottom vertical support brick 9 is located below the bottom longitudinal support brick 8 and extends vertically upwards, the bottom vertical support brick 8 is located above the bottom vertical support brick 9 and extends along the flow direction of the glass liquid, and the bottom horizontal support brick 7 is located at the bottom longitudinal support brick 8 The upper part extends along the cross-sectional direction. This solution reduces the sinking of the bottom brick 1 and the molten glass transmission pipe 4 (clarification pipe) caused by the creep shrinkage of the refractory insulation material, which can effectively ensure the safety of the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com