Improving structure for reflecting cover of electrothermal equipment

A technology of improved structure and electric heating equipment, which is applied in the field of reflectors, can solve the problems of increasing manufacturing and use costs, reducing product service life, and burning of electric heating equipment, and achieves the effects of saving energy, increasing service life, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with a preferred embodiment and accompanying drawing, the present invention will be further described,

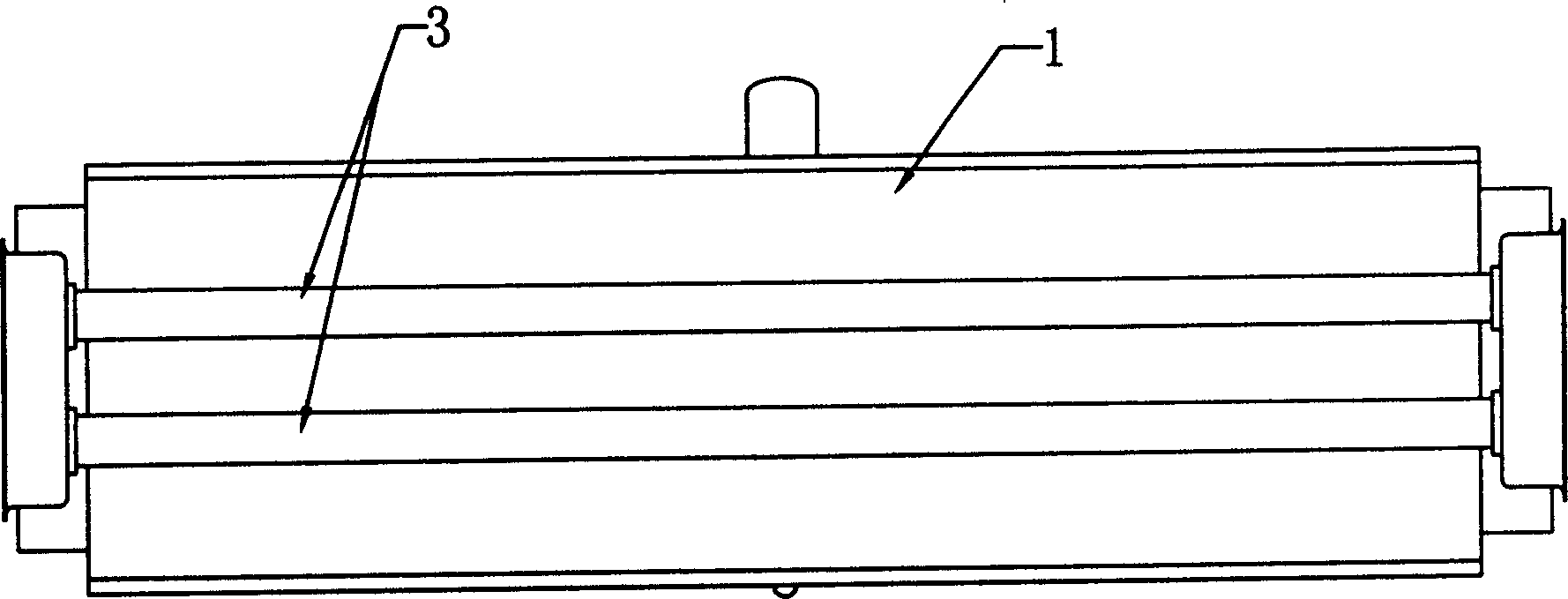

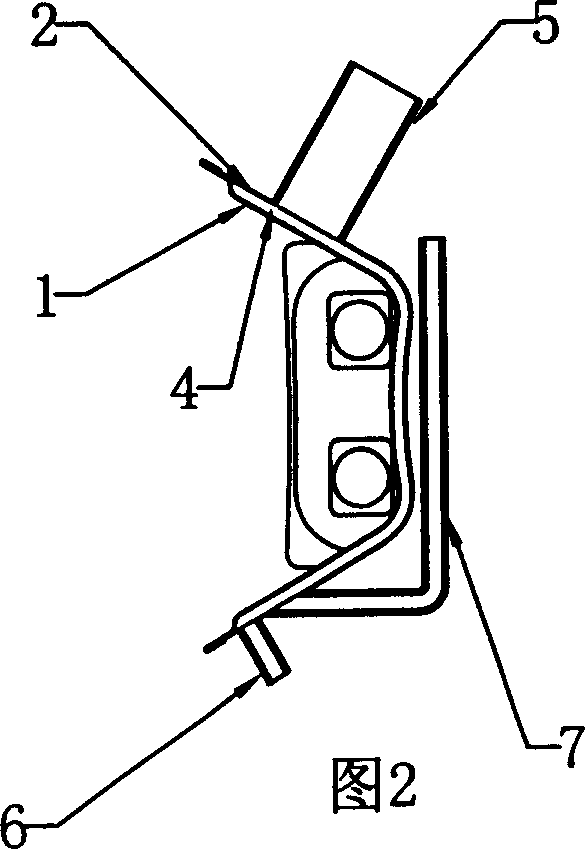

[0014] See attached figure 1 ~As shown in accompanying drawing 2, the preferred reflector of the present invention is installed on one side of the heat pipe 3 of an electric heater by welding the arc-shaped front wall 1 and the arc-shaped rear wall 2, and a wall is formed between the two walls. Cavity 4, an exhaust pipe 5 is welded on the upper part of the rear wall, and a liquid inlet and outlet pipe 6 is installed on the lower part, and the liquid such as liquid can be pumped or directly injected into the cavity 4 horizontally, or can be directly exhausted according to needs. Tube 5 is filled with water. When the electric heater works, the remaining heat evaporates the water in the cavity and other liquids that are beneficial to human health and is discharged into the air by the mouth of the exhaust pipe 5, thereby humidifying the air. In add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com