Apparatus for automatic counting and controlling of bar

A control device and automatic counting technology, which is applied in the directions of automatic packaging control, counting mechanism/item, counting objects, etc., can solve the problems such as difficulty in guaranteeing the counting accuracy of bars, achieve overlapping and crossing problems, accurate counting, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

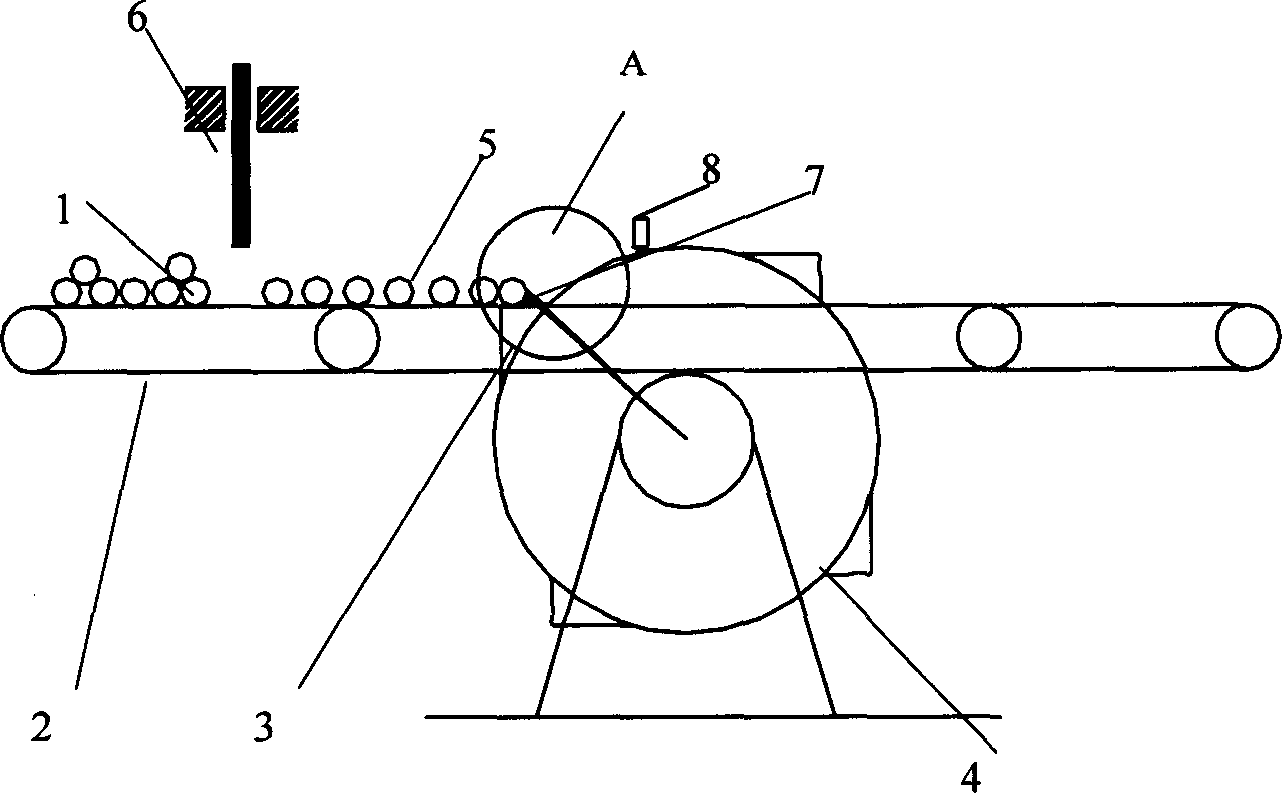

[0011] Its mechanical parts such as figure 1 As shown, the entire rod counting device is mainly composed of a sorting queuing device and a counting control device.

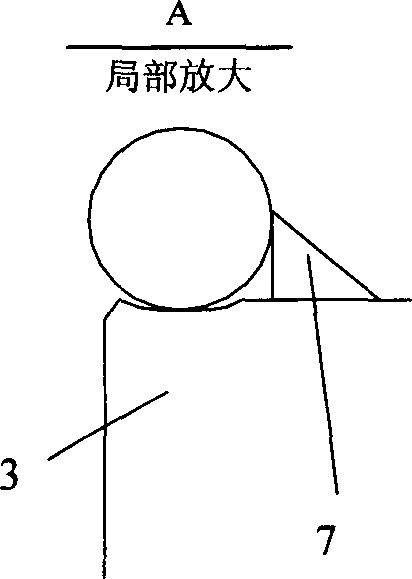

[0012] The sorting and queuing device is composed of a sorting bar baffle 6 and a queuing positioning block 7; the sorting bar baffle 6 eliminates crossing and overlapping of bars during transmission. Queuing up and positioning the stopper 7 has ensured that the bars enter regularly one by one in order before entering the feeding groove.

[0013] Counting device is made up of counting wheel 4 and counting control device. The counting wheel is designed as a disk, and four feeding grooves 3 are fixed on the disk at an angle of 90° to each other, and an infrared photoelectric sensor 8 is installed above the counting wheel. When counting, the counting device is installed on the transmission chain 2. During the transmission, the bars first pass through the sorting bar baffle 6 to eliminate overlapping and crossing ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com