Assistant spooling gear of mooring winch

A winch and mooring technology, which is applied to ships and other directions, can solve the problems of operator injury, failure to arrange neatly, and wire rope damage, and achieve the effect of reducing labor intensity and workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

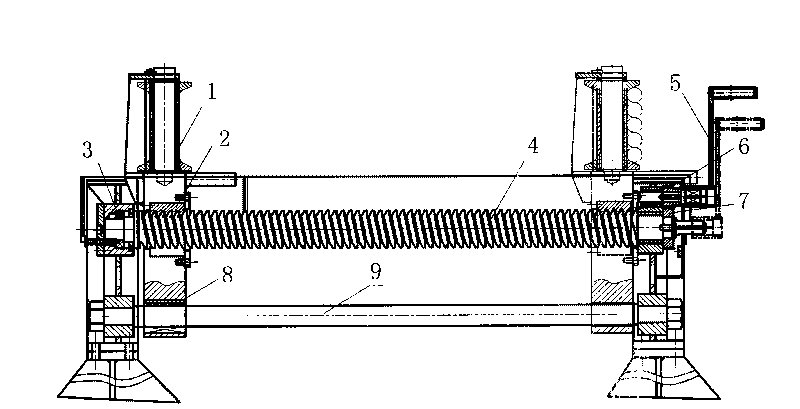

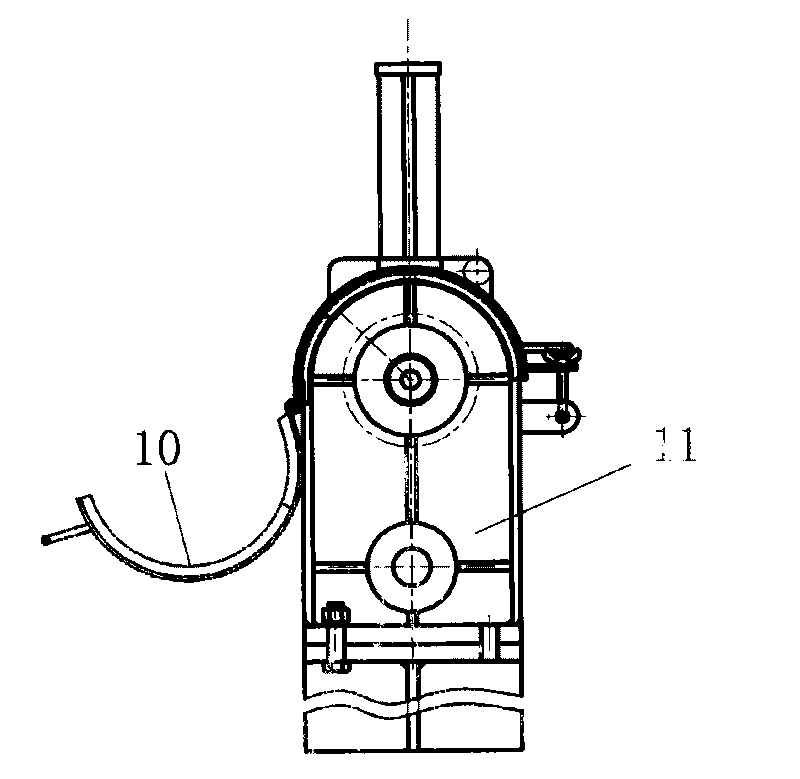

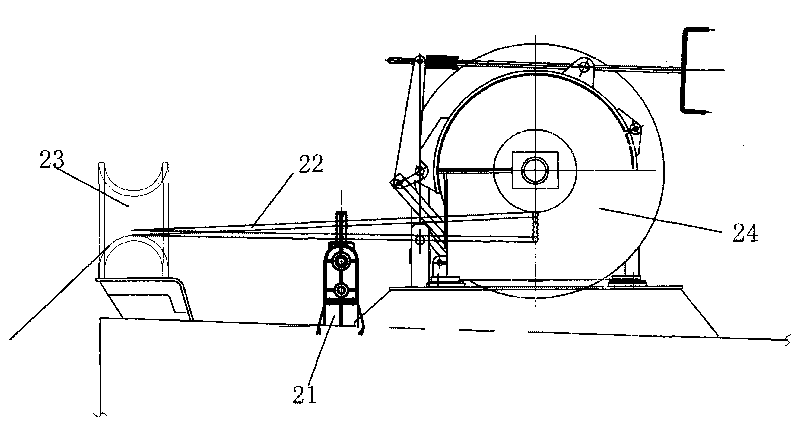

[0010] Such as figure 1 and 2 As shown, a novel mooring winch auxiliary cable-discharging device of the present invention consists of a rocking handle, a reduction gear set, a lead screw, a moving copper nut slider, a vertical roller, a linear polished rod shaft, a linear bearing, a deep groove ball bearing, Base, protective cover and other components. Specifically, in the mooring winch auxiliary cable unwinding device of the present invention, a lead screw 4 and a polished rod shaft 9 are arranged in parallel between the bases 11 on both sides. One end of the leading screw 4 is coaxially provided with a large gear 7; the middle hole of the large gear 7 is fixedly provided with a pin shaft; the pin shaft is installed with a curved handle 5 in a detachable manner. In addition, a pinion 6 is arranged on the outer side of the large gear 7; the middle hole of the pinion 6 is also fixed with a pin shaft that is provided with a curved handle 5 in a detachable manner. A roller fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com