Construction device of high-pressure impact water-type Lassen steel sheet pile

A Larsen steel sheet pile and construction device technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as low work efficiency, high turnover times, and increased compactness, and achieve easy maintenance and replacement, and increased use The effect of improving life and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

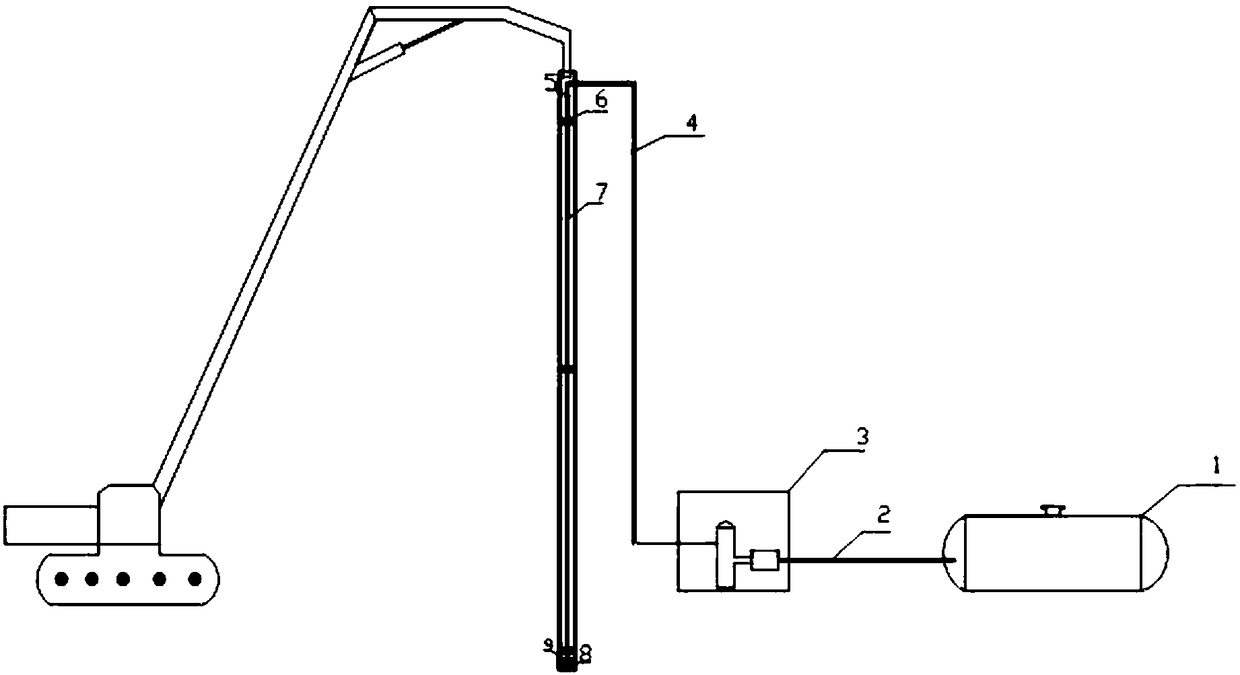

[0014] From figure 1 It can be seen that a high-pressure impact water-type Larsen steel sheet pile construction device (hereinafter referred to as the Larsen steel sheet pile construction device) includes the Larsen steel sheet pile 9, which has a vertical straight The groove is characterized in that the construction device of the high-pressure impact water-type Larsen steel sheet pile also includes a water storage tank 1, a low-pressure hose 2, a high-pressure water pump 3, a high-pressure hose 4, a high-pressure threaded joint 5, a fixing plate 6, and a main pressure Pipe 7 and cone nozzle 8, the water storage tank 1 is placed on the ground, a low pressure hose 2 is provided on the water outlet of the water storage tank 1, and a high pressure water pump is provided at the water outlet end of the low pressure hose 2 3. A high-pressure hose 4 is provided on the water outlet of the high-pressure water pump 3, and the high-pressure water pump 3 is connected with a separately prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com