A method for packaging vehicle supercharger turbine and gas compressor impeller casting

A supercharger turbine and packaging method technology, which is applied in the direction of packaging, packaging food, machine containers, etc., can solve the problems of high cost of foam boards, non-environmental protection of foam materials, and pollution of operating sites by foam scraps, so as to save materials and operate convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below is that the present invention is described in detail in conjunction with the embodiment in the accompanying drawings:

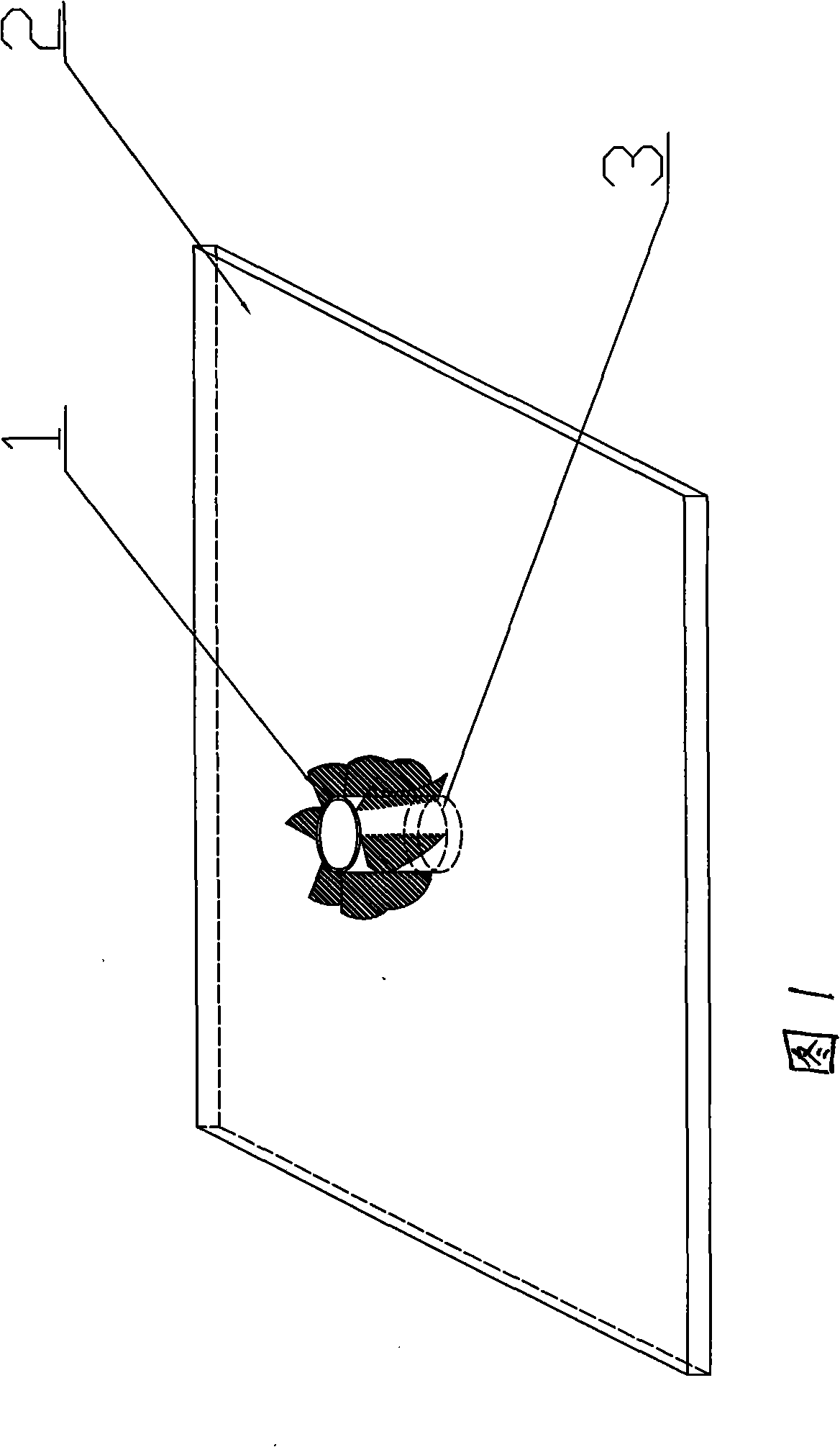

[0011] As shown in the figure, according to the diameter of the small head of the turbine or compressor impeller casting 1, a through hole 3 smaller than or equal to the diameter of the small head is opened on the corrugated board 2 in the carton. The diameter of the through hole 3 is not less than the diameter of the small head of the casting 1. The position of the bores 3 relative to each other is determined by the large outer diameter of the cast part 1 . The small end of the casting 1 is inserted into the fixed position in the through hole 3 . This method effectively solves the problem of the turbine and compressor impeller being squeezed together due to rollover during transportation, saves materials, is simple and beautiful, environmentally friendly, and easy to operate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com