Wellhead cable protection device and method for tripping operation of oil submersible cable

A technology for submersible cables and tripping drilling, which is applied in drilling equipment, drill pipes, drill pipes, etc., can solve the problems of cable elevator extrusion, deformation, insulation damage, etc., to ensure stability, avoid stranded wires, Avoid scratching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

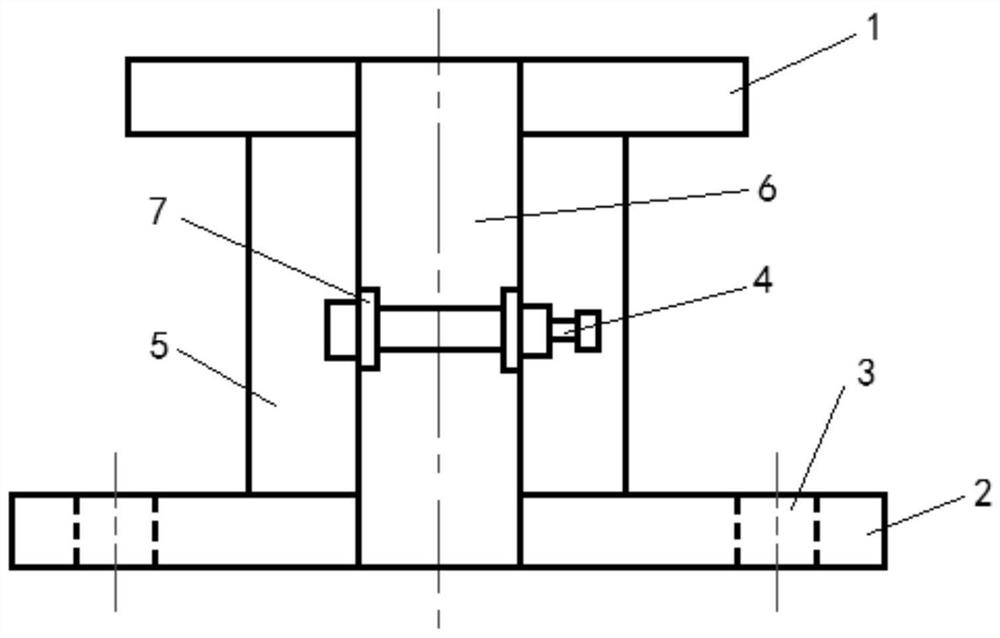

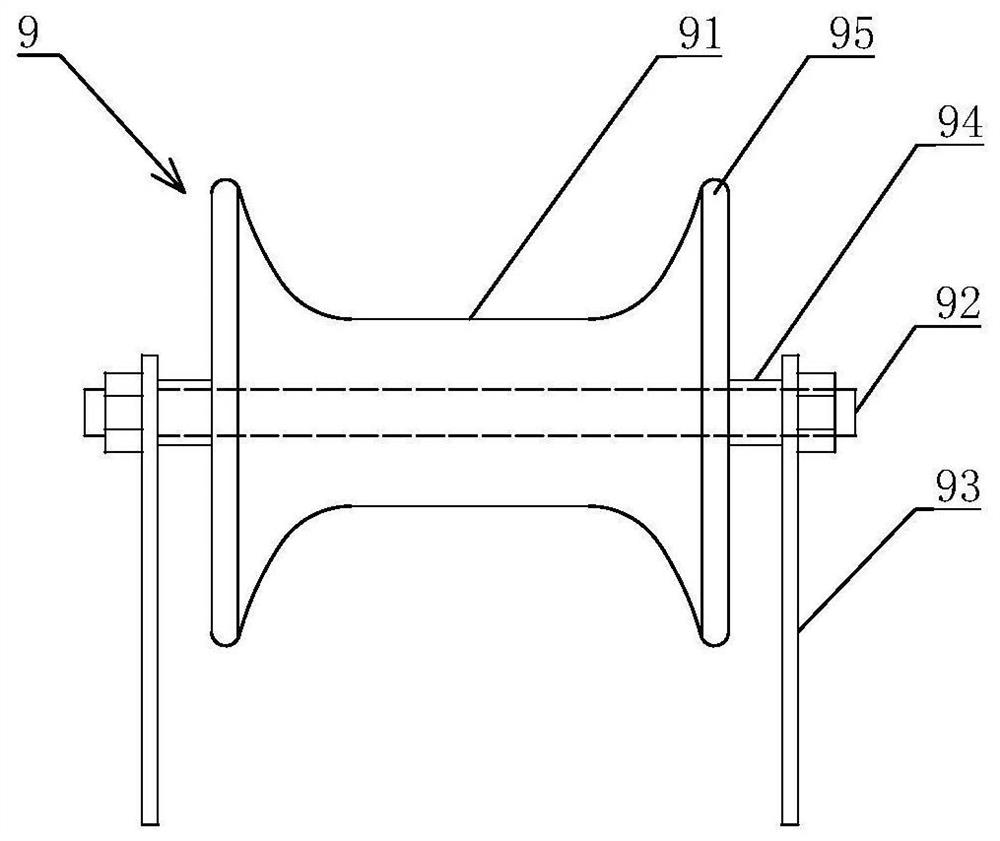

[0049] Such as figure 1 As shown, center the connection base 2 of the wellhead cable protector for the tripping operation of the submersible cable on the lower flange of the wellhead of the oil well, and install the bolts in the eight bolt holes 3 of the connection base 2 to fix the support body 5 on the wellhead superior. When lifting and unloading the oil pipe, the cable is tightened along the outer side of the rolling shaft 4 to ensure that the speed of the cable and the oil pipe are synchronized. When loading and unloading the oil pipe, the elevators are placed on the support platform 1 of the cable protector to prevent the elevator from damaging the cable. Wherein, the middle part of the cutout 6 is provided with an outwardly extending lug 7, and the rolling shaft 4 is detachably set through the lug 7; the constraining shaft 9 is correspondingly fixed on the lug 7 on the same side through the connecting end plate.

example 2

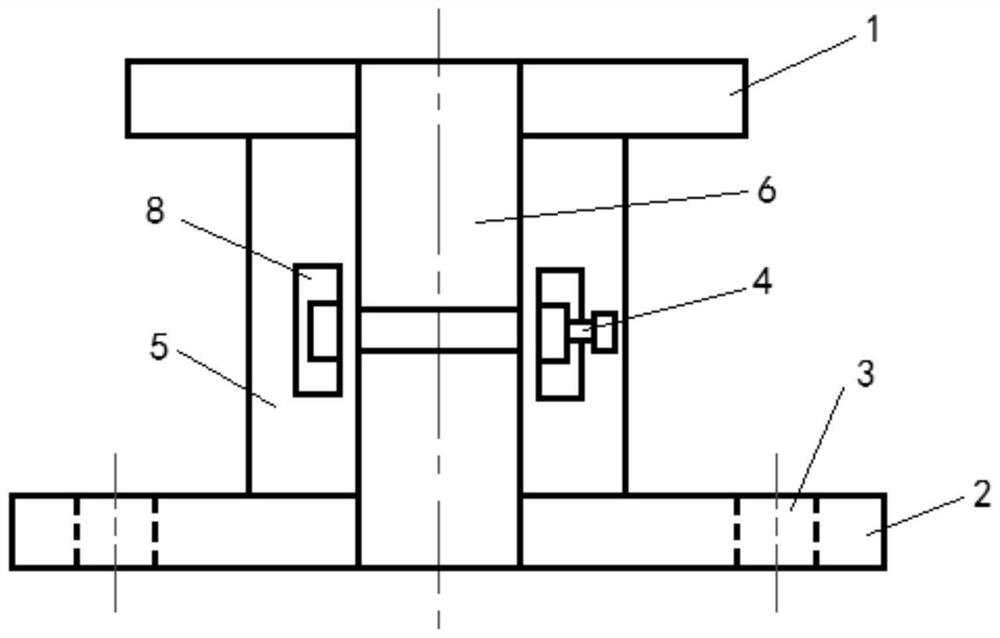

[0051] Such as figure 2 As shown, the support body 5 is symmetrically provided with grooves 8 located on both sides of the middle part of the cutout 6, a connecting wall is formed between the groove 8 and the cutout 6, the rolling shaft 4 is detachably set through the connecting wall, and the restraining shaft 9 is connected through the The end plates are correspondingly fixed on the connecting wall on the same side; other structures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com