Separable filter unit

A technology of separation filtration and filter cartridge, applied in the direction of filtration separation, separation method, fixed filter element filter, etc., can solve the problems of long settling time, impact on personal health, failure to reach the designed production capacity, etc., and achieve convenient use and high filtration effect ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

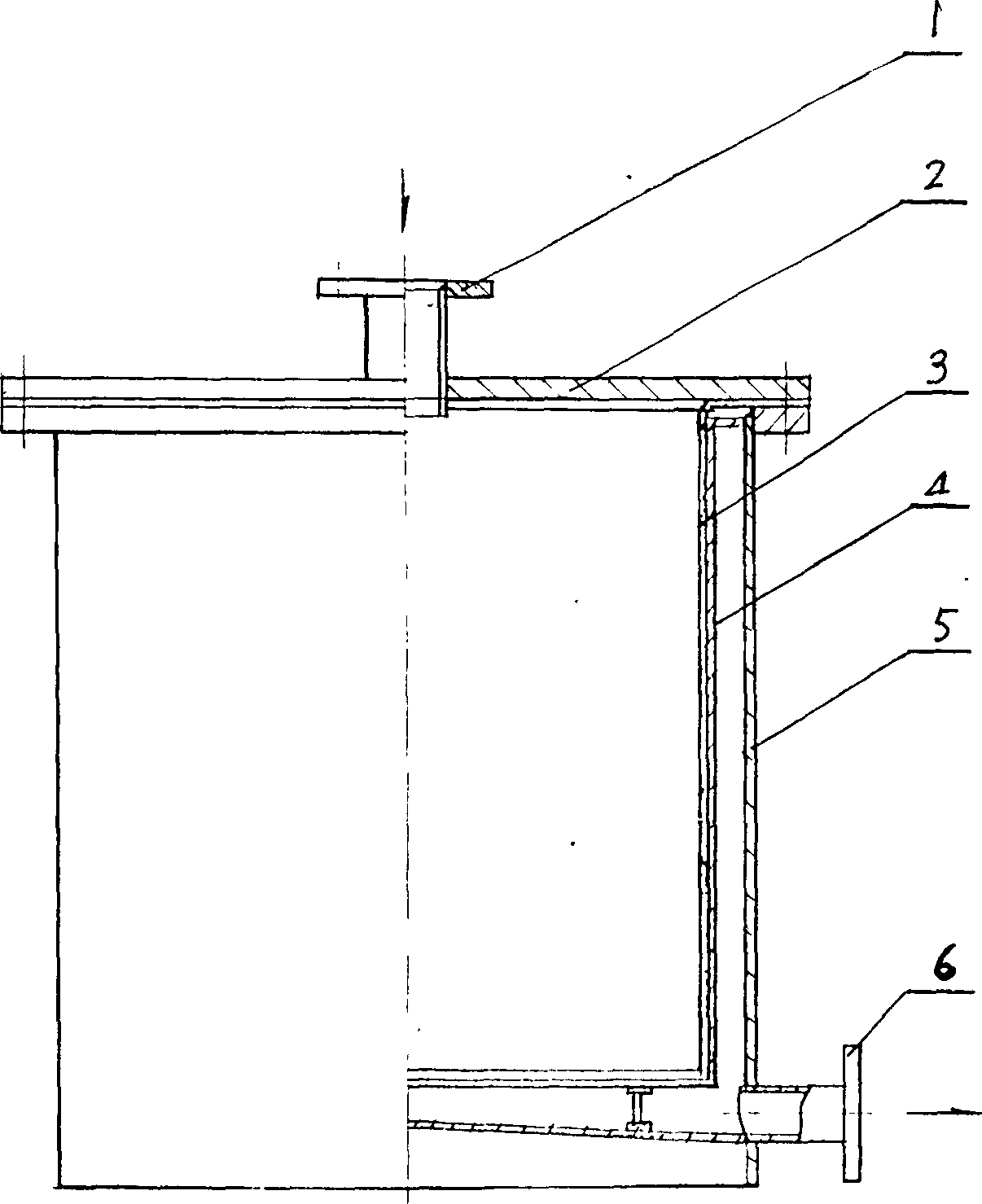

[0009] Depend on figure 1 It can be seen that the separable filter device of the present invention comprises an upper gland 2, a filter cloth 3, a filter cartridge 4 and an outer cylinder 5, and a mixed liquid material inlet 1 is installed at the center of the upper gland 2, the filter cloth 3 is a cylinder, and the bottom The round bottom is sewn, the upper opening is sewn with 90° flanging, and its outer wall is close to the inner wall of the filter cartridge 4. The filter cartridge 4 is also a cylindrical barrel body, and the bottom is supported on the bottom plate of the outer cylinder 5 with a bottom frame. The mouth is provided with an outer edge that can be supported with the inner wall of the outer cylinder 5, and the side wall of the filter cartridge 4 has a through hole to allow the filtrate to flow out. Described urceolus 5 is also cylindrical staving body, and upper mouth is welded flange, and the clear liquid outlet 6 is opened on the lower side of its cylinder wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com