Vehicle for loading and unloading stuff

A technology for loading and unloading materials and frames, which is applied in the directions of loading/unloading, supply devices, transportation and packaging, etc. It can solve the problems of difficult synchronous movement, complex structure and pipeline of loading and unloading trucks, and heavy maintenance workload, etc., and achieve structural Simple, small maintenance workload, convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

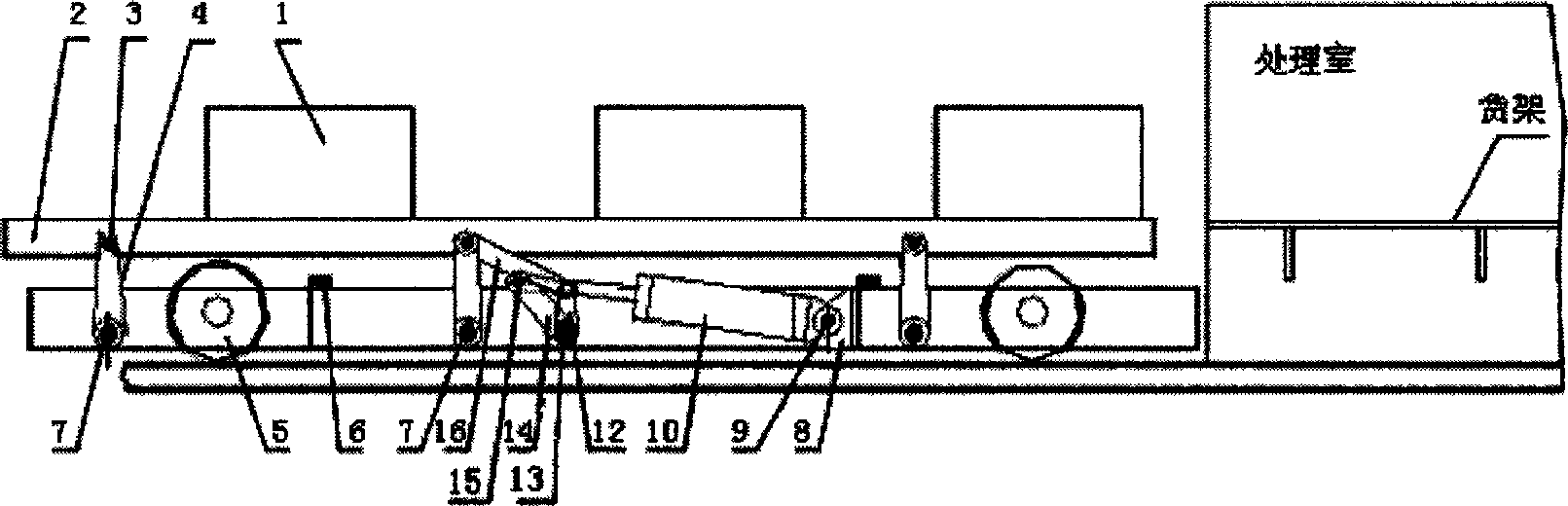

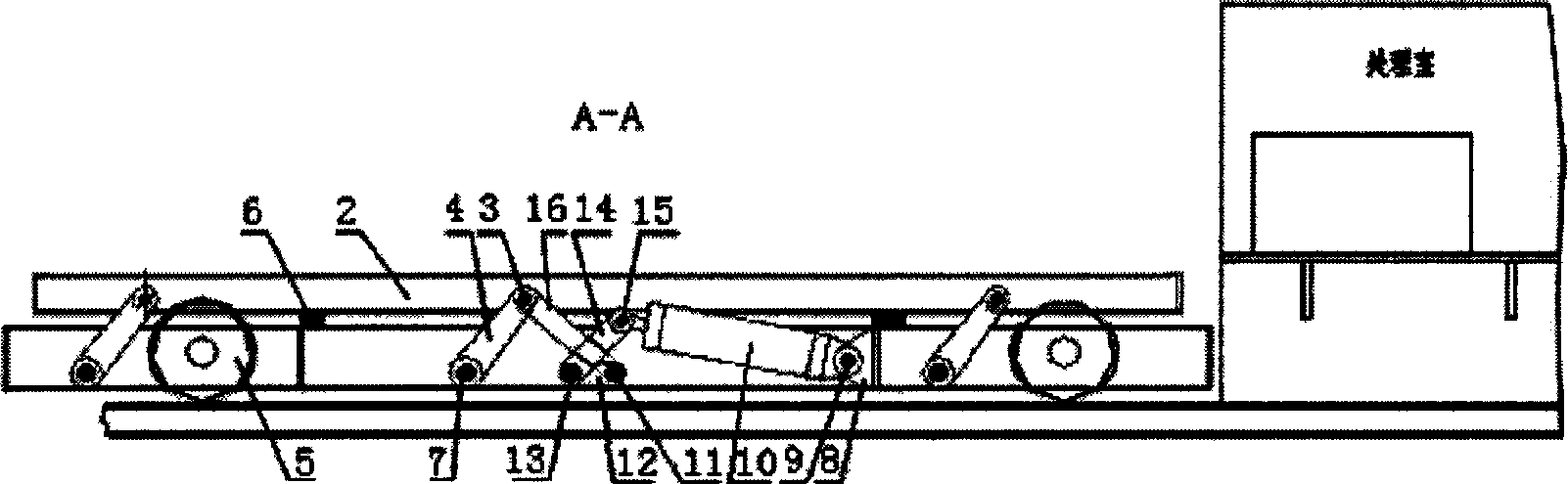

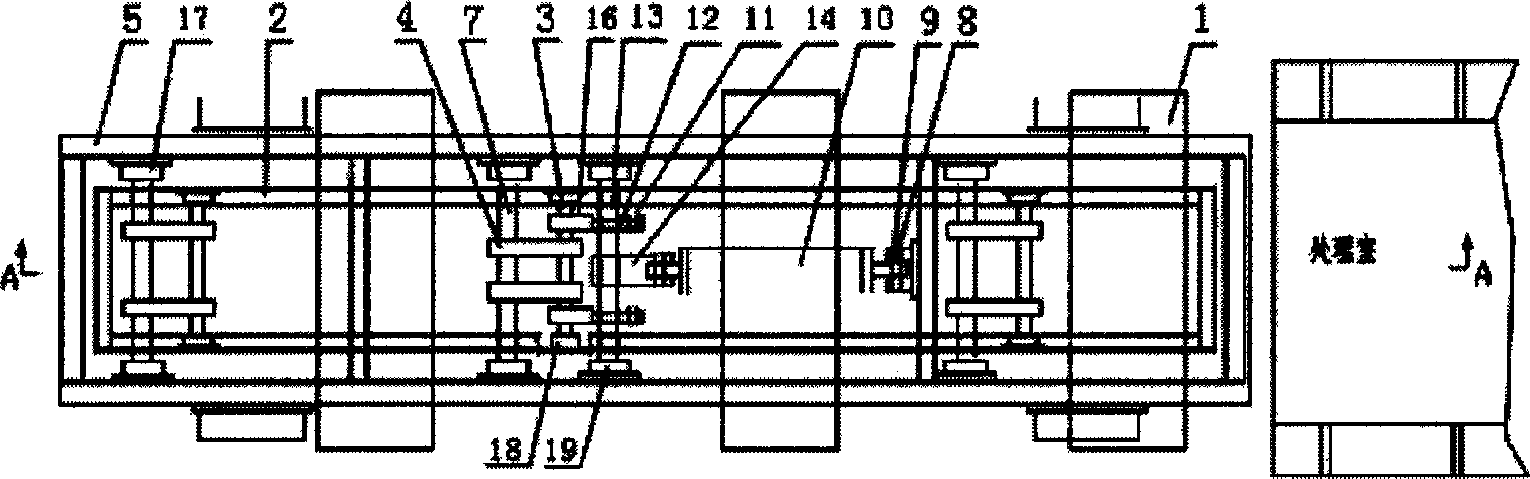

[0014] Embodiments of the present invention: design according to the weight and the length of the materials to be loaded and unloaded, select and purchase the oil cylinder 10, and make each part. Assemble as shown. First, the two ends of the connecting rod 4 are respectively hinged with the shaft 3 and the shaft 7, and the bearing housing 17 is installed at both ends of the shaft 7; the connecting rod 16 is installed on the shaft 3, and the bearing housing 18 is installed at both ends of the shaft 3; Then the bearing seat 17 is fixed on the walking vehicle frame 5, and the bearing seat 18 is fixed on the movable frame 2; secondly, the crank throw 12 and the crank 14 are respectively rigidly installed on the shaft 13, and the bearing is installed on the shaft 13. After the seat 19, it is fixed on the walking frame 5; the third, the other end of the crank throw 12 is connected with the connecting rod 16 through the pin 11, and the other end of the crank 14 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com