Servo valve needle hot runner system

A technology of hot runner and valve needle, applied in the field of servo valve needle hot runner system, can solve the problems of large glue flow, economic loss, affecting product molding quality and molding cycle, etc., to achieve precise control and avoid asynchronous effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

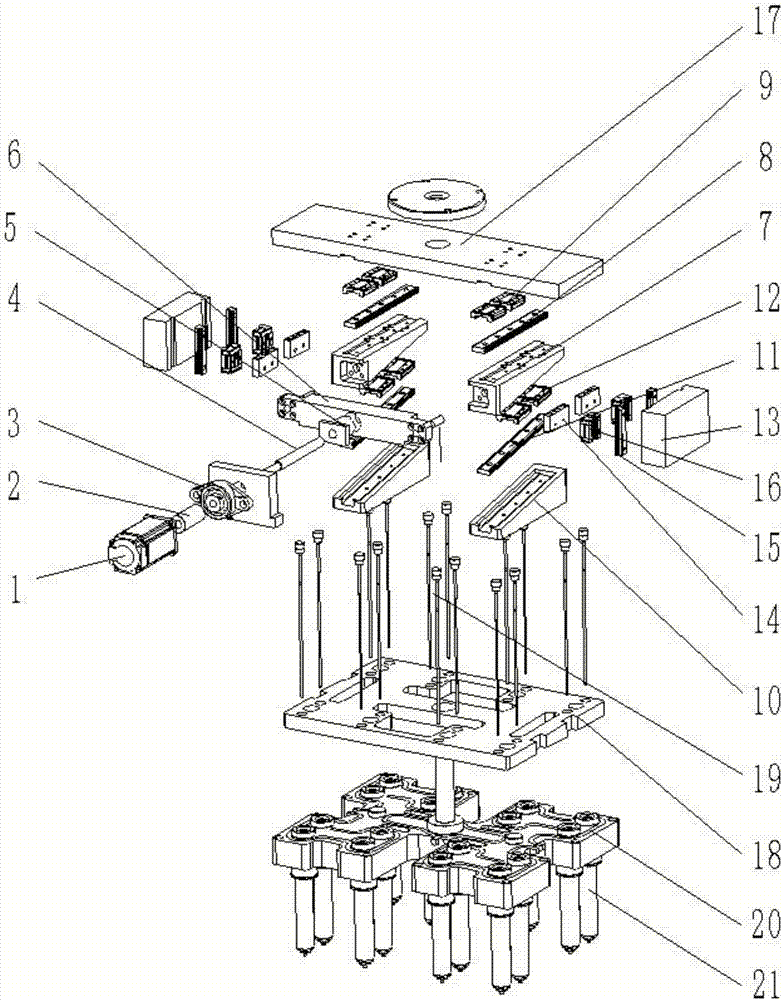

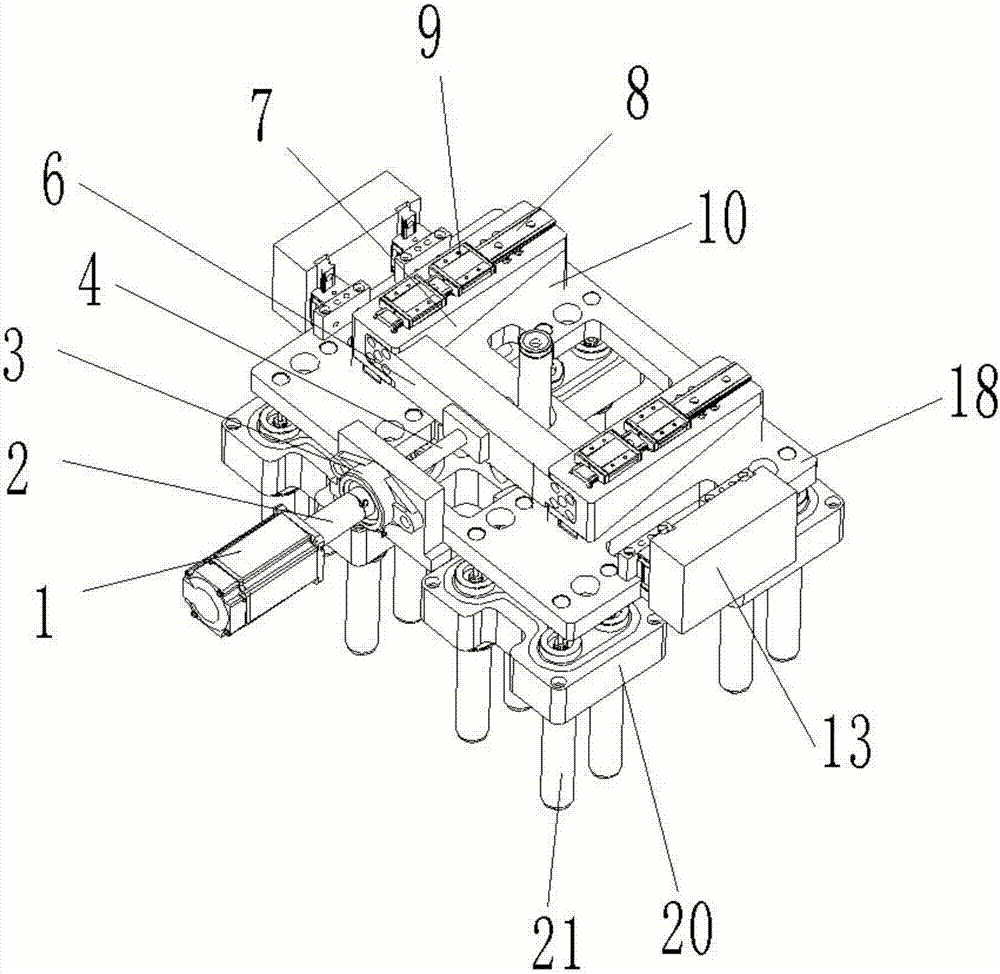

[0014] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] See attached figure 1 -2, the present invention includes a servo motor 1, a valve needle fixing plate 18 and a manifold 20, the manifold 20 is provided with a plurality of hot nozzles 21, the drive shaft of the servo motor 1 is connected to one end of the coupling 2, and the coupling 2 The other end is connected with the ball screw 4, the ball screw 4 is supported and installed on the bearing seat 3 and the ball screw nut 5, the ball screw nut 5 is installed on the main push plate 6, the drive shaft and coupling of the servo motor 1 2 coincides with the axis of the ball screw 4, the main push plate 6 is provided with a screw hole, the ball screw 4 matches the screw hole on the main push plate 6, and the main push plate 6 is connected with two upper push plates 7, Two lower push plates 10 are installed on the need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com