Casting construction method for asphalt concrete anti-infiltration core wall of earth rockfill dam

An asphalt concrete and construction method technology, applied in dams, buildings, sheet pile walls, etc., can solve problems such as poor overall stability and anti-seepage effect, and achieve good laying effect, lower construction temperature, and good flatness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

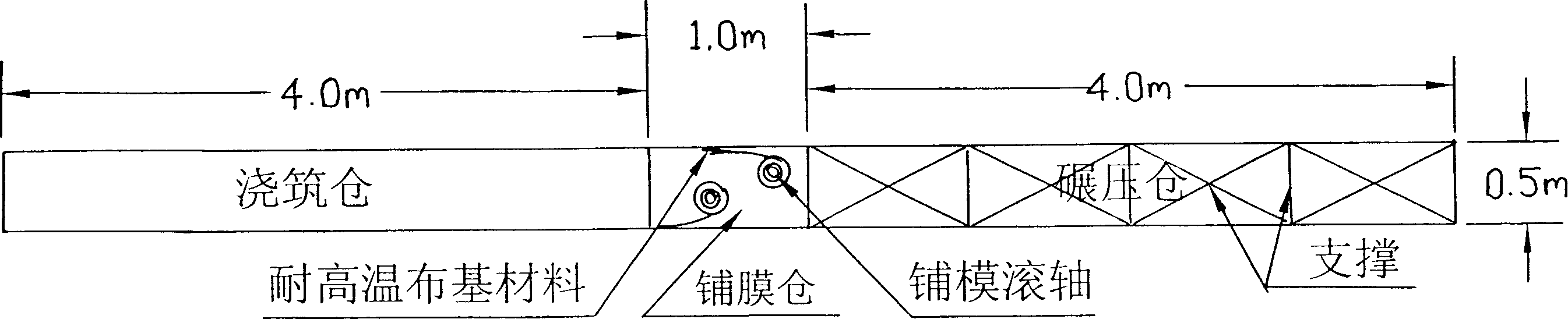

[0035] a. Lay the formwork. During construction, lay the formwork vertically on the base of the core wall so that the centerline of the formwork and the centerline of the core wall completely coincide. The formwork adopts a sliding formwork; the width is 150cm, and it is made of 10mm steel plate;

[0036] b. Lay high-temperature-resistant flexible cloth-based materials. After the formwork is laid, lay high-temperature flexible cloth-based materials with a width slightly larger than the thickness of asphalt concrete paving close to the inside of the formwork. The width of the high-temperature flexible cloth-based material is 10cm higher than that of the formwork. High-temperature flexible The cloth base material adopts polyester high temperature resistant 230 ℃ non-woven fabric produced by Dalian Evergrande High-tech Material Development Co., Ltd.

[0037] c. Pave the transition material and roll the transition material, pave the transition material on the outside of the formwor...

Embodiment 2

[0041] a. Lay the formwork. During the construction, lay the formwork vertically on the core wall that has been built, so that the center line of the formwork and the center line of the core wall completely coincide. The formwork adopts an assembled movable formwork; the width is 100cm;

[0042] b. Lay high-temperature-resistant flexible cloth-based materials. After the formwork is laid, lay high-temperature flexible cloth-based materials with a width slightly larger than the thickness of asphalt concrete paving close to the inside of the formwork. The width of the high-temperature flexible cloth-based material is 8cm higher than that of the formwork. The base material is polyamide fiber non-woven fabric, which can withstand high temperature of 200 ℃;

[0043] c. Pave the transition material and roll the transition material, pave the transition material on the outside of the formwork and pass the rolling;

[0044] d. Pave asphalt concrete, pave asphalt concrete into the formwo...

Embodiment 3

[0049] a. Lay the formwork. During the construction, lay the formwork vertically on the core wall that has been built, so that the center line of the formwork and the center line of the core wall completely coincide, and use a sliding formwork; the width is 80cm;

[0050]b. Lay high-temperature-resistant flexible cloth-based materials. After the formwork is laid, lay a high-temperature flexible cloth-based material with a width slightly larger than the thickness of asphalt concrete paving close to the inside of the formwork. The width of the high-temperature flexible cloth-based material is 9cm higher than that of the formwork. Polyacrylonitrile Fiber non-woven fabric, resistant to high temperature of 230°C.

[0051] c. Pave the transition material and roll the transition material, pave the transition material on the outside of the formwork and pass the rolling;

[0052] d. Pave asphalt concrete, pave asphalt concrete into the formwork and make it dense;

[0053] e. Sliding f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com