High speed muting structure for ball screw

A ball screw, silent technology, applied in belts/chains/gears, mechanical equipment, transmissions, etc., can solve problems such as complex structure, easy parts failure, and unfavorable product manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

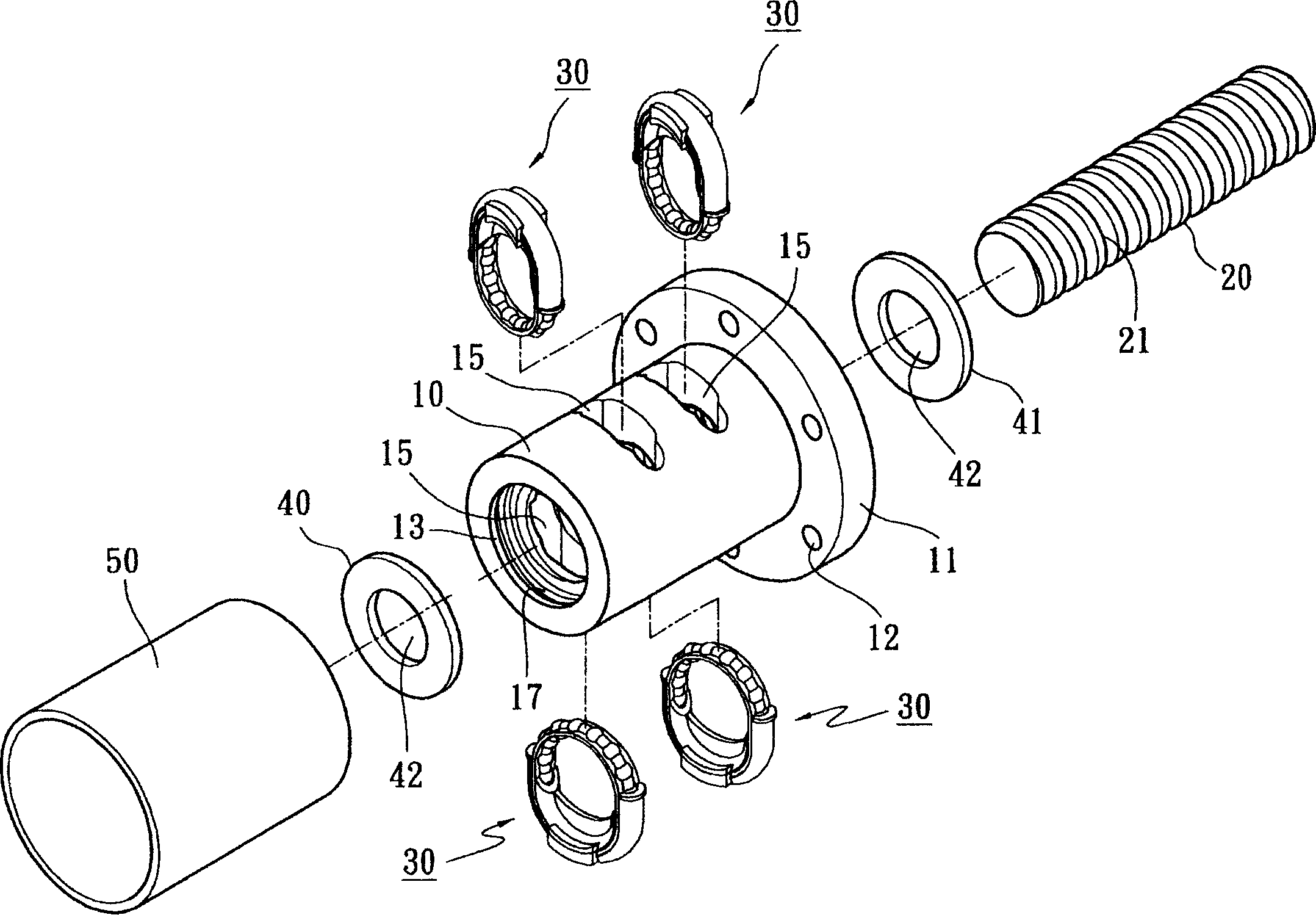

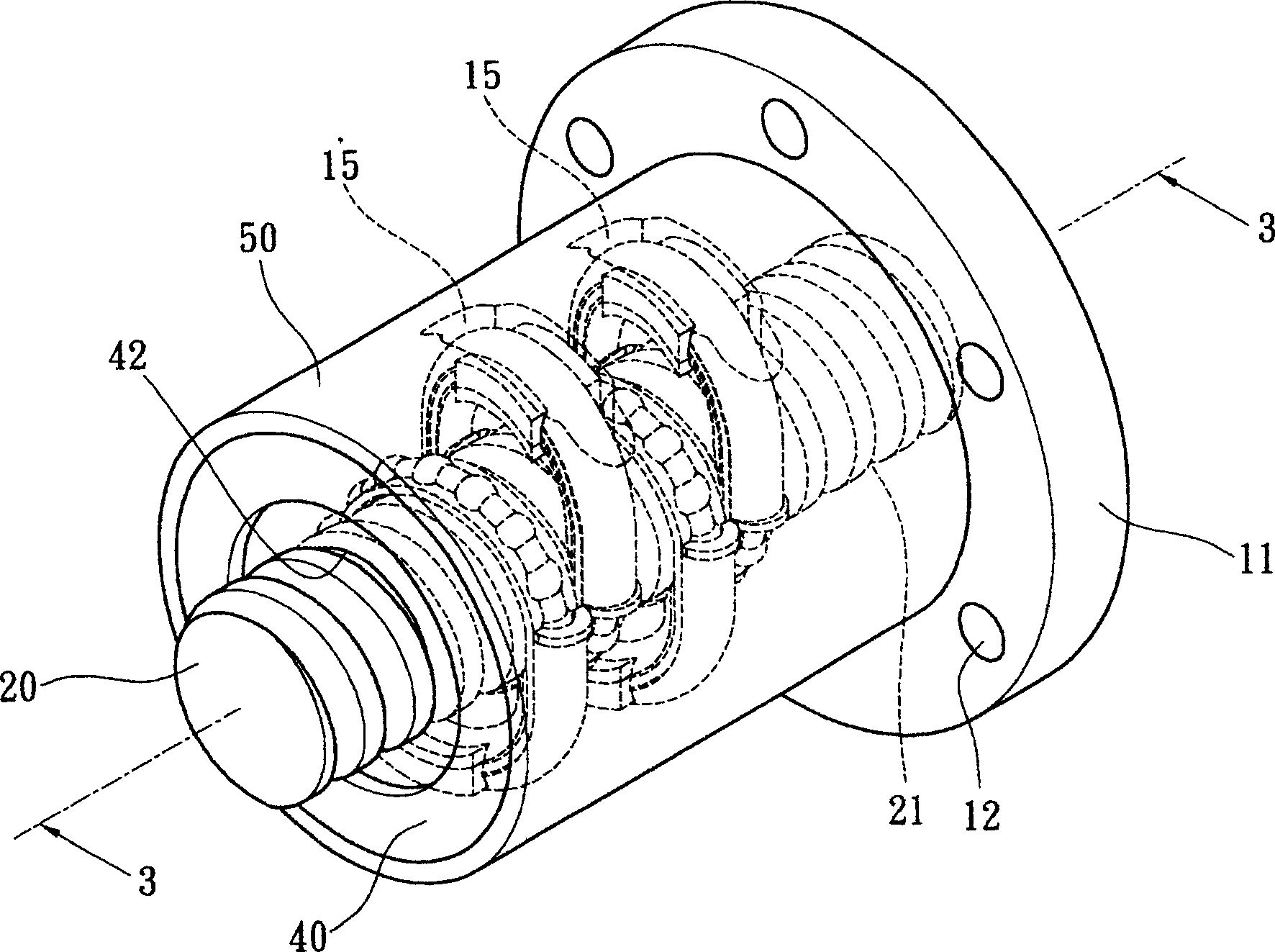

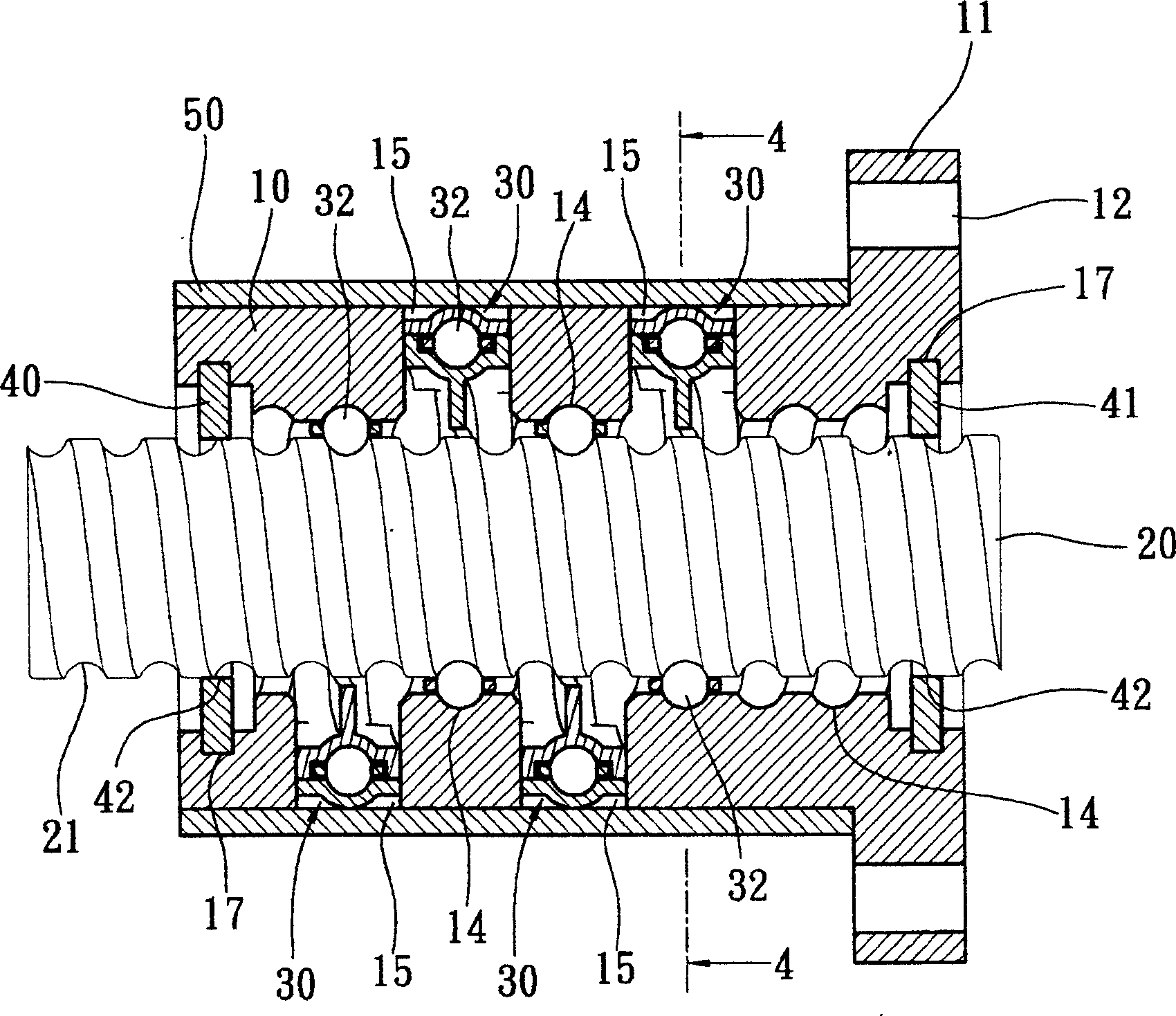

[0020] Please refer to Figure 1-Figure 3 As shown, the high-speed silent structure of the ball screw of the present invention mainly has a fixed seat 10 of a shaft sleeve body, a screw shaft 20, more than two ball rings 30 in pairs, two sealing sheets 40, 41 and a ring Set of 50 consists of;

[0021] Wherein, the shape of the fixing base 10 is in the shape of a sleeve, and one end is connected to an expanded vertical wall flange 11, and a plurality of perforations 12 are provided on the flange to provide bolts (not visible) to penetrate and lock on the linear slide rail device seat body etc. Be provided with through inner hole 13 in the center of fixed seat 10, be provided with spiral groove 14 in its inner hole (refer to image 3 Shown); on the fixed base 10, be provided with a hollowed-out slot 15, the hollowed slot 15 is arranged on the fixed base 10 in pairs, that is, when one hollow slot 15 is located at the upper end of the fixed base, and the relative position ( The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com