Ink jet recording apparatus

An inkjet recording and recording head technology, which is applied to printing devices, inks, coatings, etc., can solve the problems of wrinkles, curling and curling of printed products, and excessive ink ejection, so as to improve ink viscosity and suppress short-term curl effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

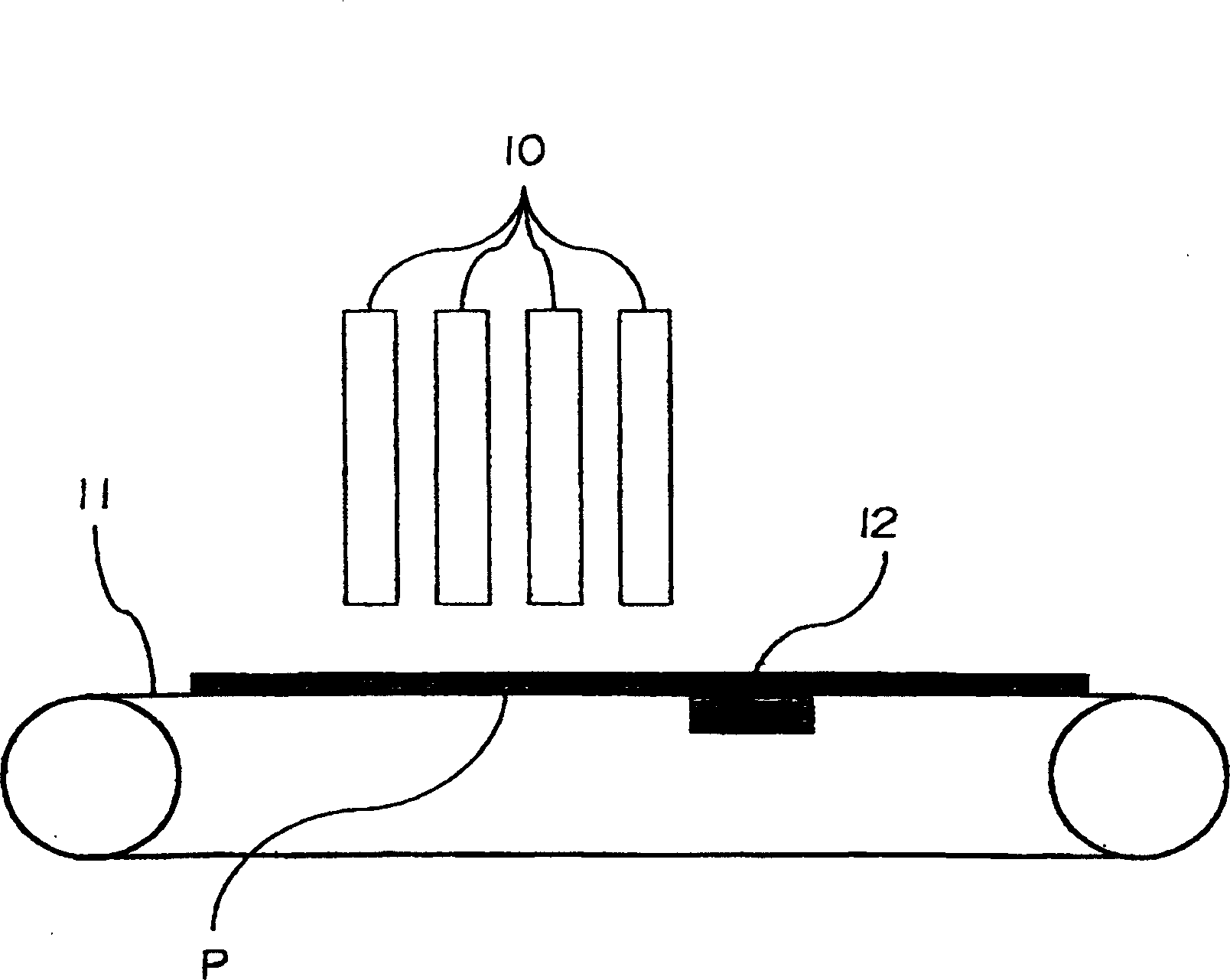

[0030] use figure 1 The apparatus of this embodiment shown and plain paper as a specific example of the recording medium P were measured for curl when the amount of ink applied per unit area to the plain paper was 100%. Examples of inks used are shown below.

[0031] Ink 1C.I

[0032]Direct Blue-199 3.5% by weight

[0033] Isopropanol 2.5% by weight

[0034] Hexatriol 27% by weight

[0035] Urea 2% by weight

[0036] acetylenol EH 1% by weight

[0037] Water 64% by weight

[0038] Ink 2C.I

[0039] Direct Blue-199 3.5% by weight

[0040] Isopropanol 2.5% by weight

[0041] Hexatriol 17% by weight

[0042] Urea 10% by weight

[0043] acetylenol EH 1% by weight

[0044] Water 64% by weight

[0045] Ink 3C.I

[0046] Direct Blue-199 3.5% by weight

[0047] Isopropanol 2.5% by weight

[0048] Trimethylolpropane 17% by weight

[0049] Urea 10% by ...

Embodiment 2

[0057] use Figure 5 The device of the above-mentioned device measures the curl when the amount of ink applied per unit area on plain paper as the recording medium P is 100%. As an example of the ink, the ink listed in the above-mentioned Example 1 was used, and the heater was activated when the printing amount of the ink exceeded a predetermined amount.

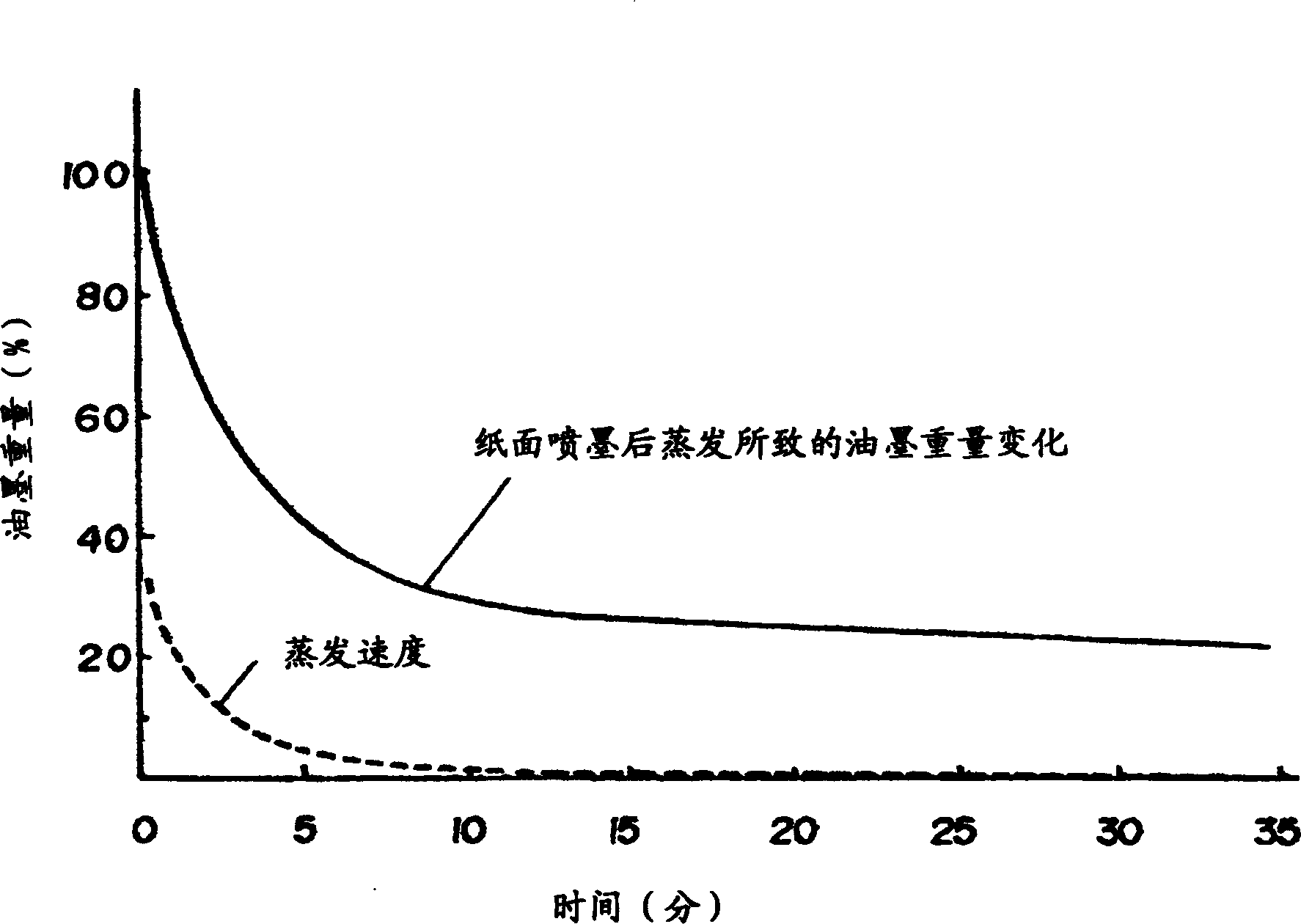

[0058] As described in Example 1 above, short-term curling tends to occur when the viscosity of the ink decreases. The short-term curl suppression effect is equivalent to that of the recording medium P. The result is not only less short-term lift, but also effective in curbing long-term frizz.

[0059] (Comparative example) As a comparative example with respect to Example 1 and Example 2, the same ink was used and the curl was measured when short-term curl suppression treatment was not performed. At this time, the curl measurement method is as follows: Figure 6 As shown, the amount of warping of the four corners of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com