Clamping forming core shaft of welding pipe and clamping adjustment

A technology of mandrel and welded pipe, which is applied in the field of metal plate processing and forming, can solve the problems of low processing efficiency, steel plate falling out, and affecting the quality of steel pipes, etc., and achieve the effect of improving processing efficiency, reasonable design and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

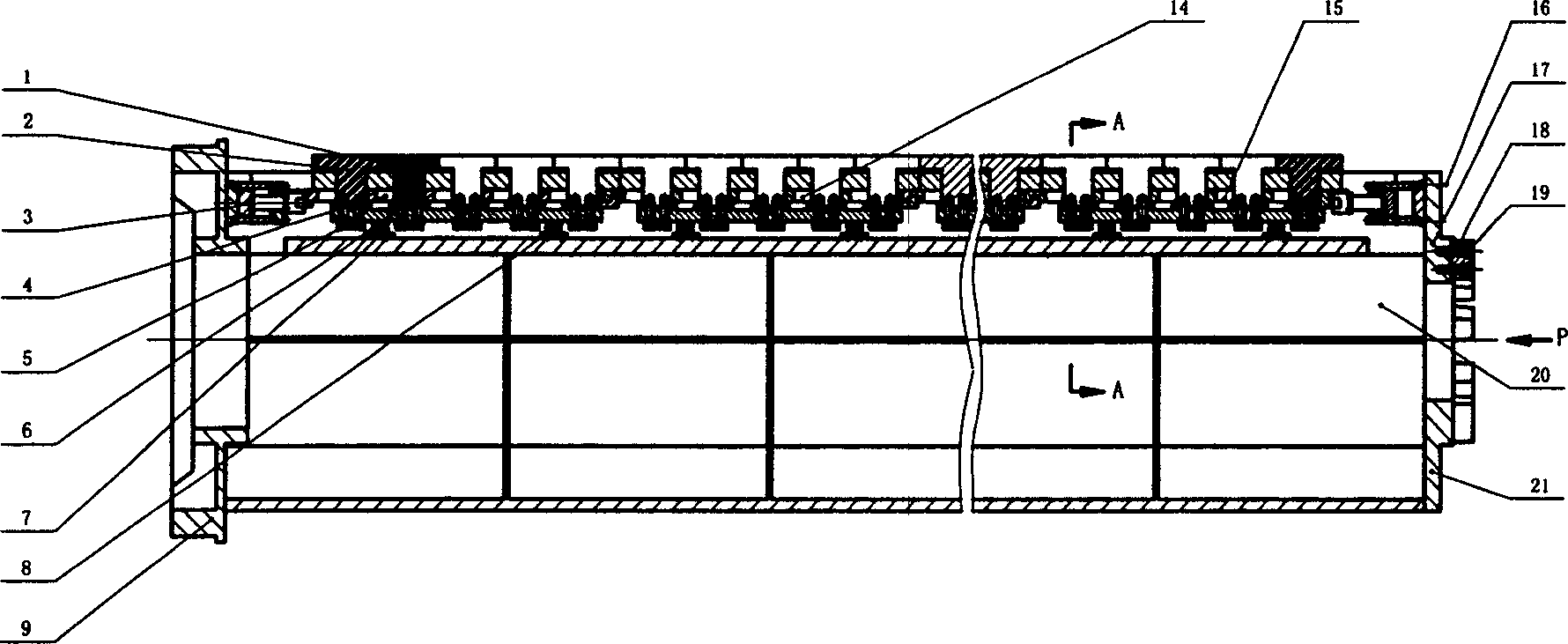

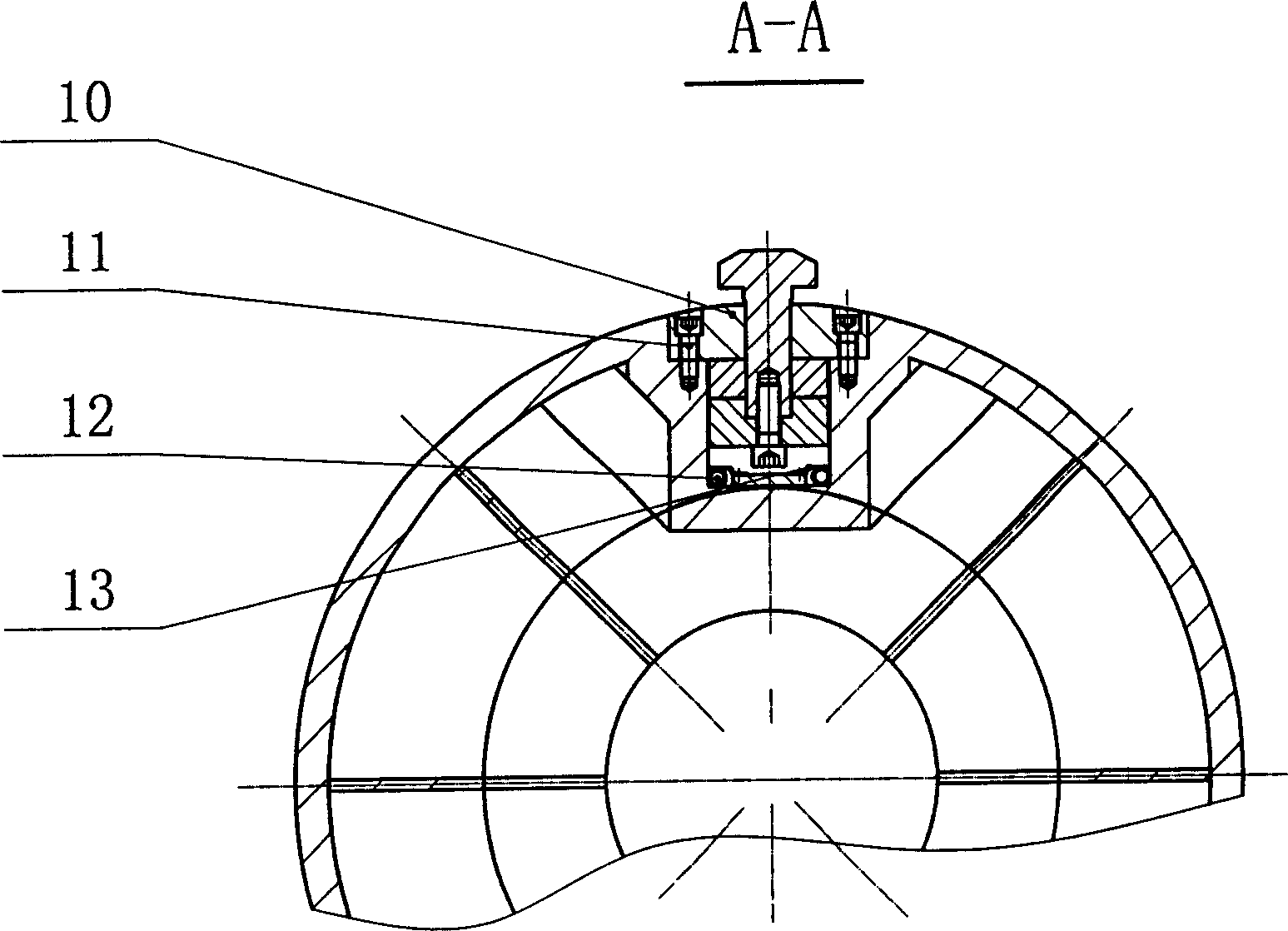

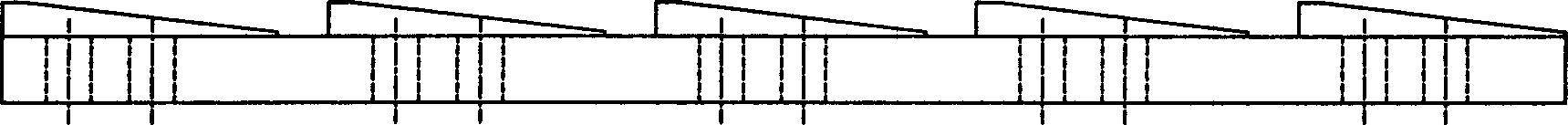

[0016] as attached figure 1 , attached figure 2 As shown, the coil forming mandrel 21 in the large LSAW pipe production process of the present invention is composed of an I-shaped chuck 1, an oil cylinder 3, an oblique pressure block 4, a screw 5, an oblique support block 6, a spring 7, Spring seat 8, chuck 9, pressure plate 10, screw 11, oil pipe 12, oil pipe pressure plate 13, oblique pressure block 14, oblique pressure block 15, screw 16, end plate 17, oblique block 18, screw 19, mandrel cylinder 20 Composition, there is a groove along the axial direction on the surface of the mandrel 21, there is a step on the groove, the pressure plate 10 is fixed on the groove step by the screw 11, the oil pipe 12 is arranged on the bottom surface of the groove, and the oil pipe pressure plate 13 covers On the oil pipe 12, more than one I-shaped chuck 1 is arranged in the groove, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com