Directional wheel

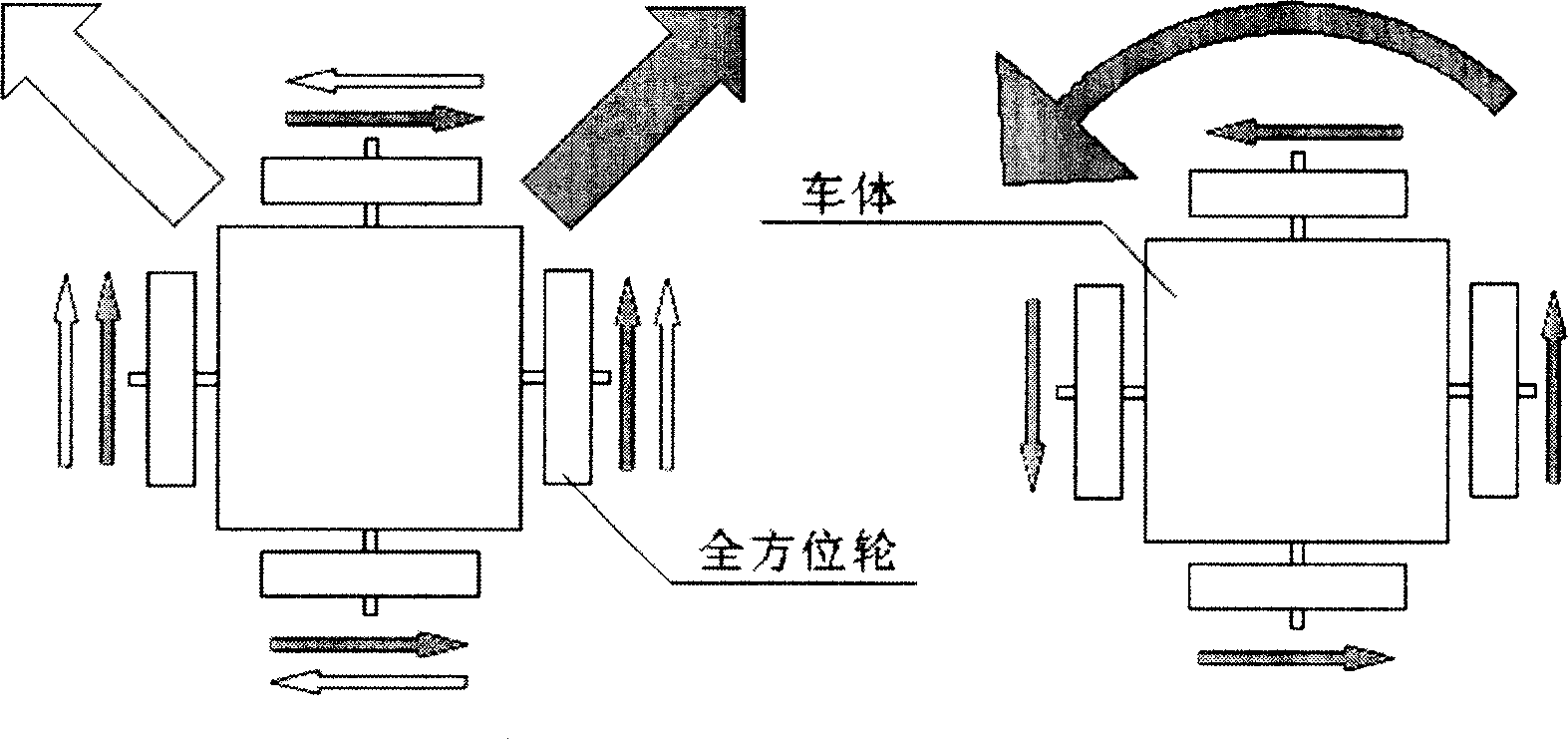

A technology of omni-directional wheels and steel pipes, which is applied in the field of robots, can solve problems such as hindering the popularization and application of omni-directional mobile robot technology, affecting value, and complex design of omni-directional wheels, so as to improve the popularity of use, simplify production, and reduce vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

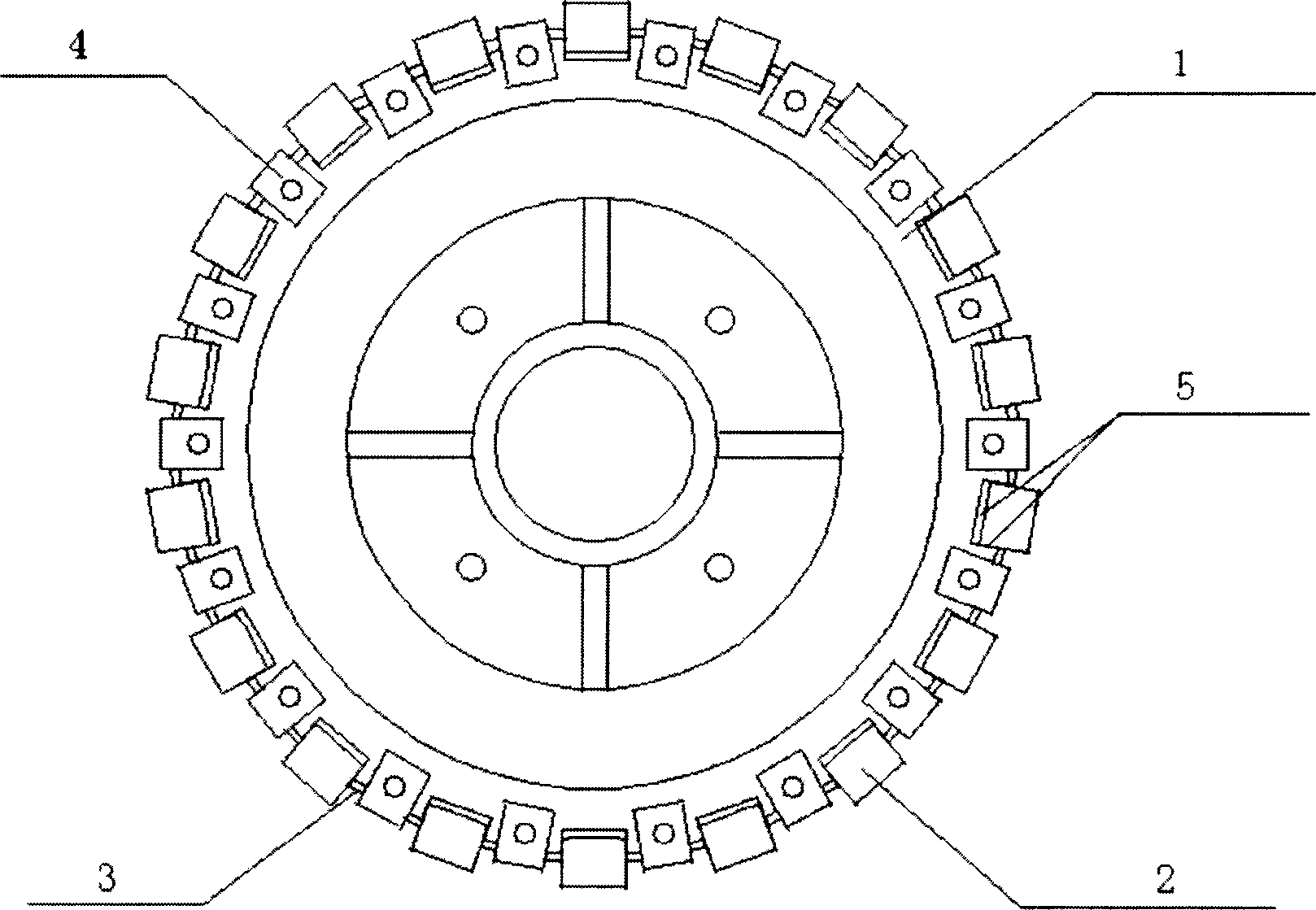

[0015] The omnidirectional wheel front view of the present invention is as follows figure 1 As shown, it includes a large wheel 1, several identical small wheels 2, steel rings 3 and steel pipe mounting parts 4, the shaft hole of the large wheel 1 is connected to the drive shaft, and several grooves are equally spaced on the outer circumference of the large wheel 1 It is used to install the small wheel. There is a semicircular groove on the end surface of the outer ring of the large wheel 1. The radius of the semicircular groove is equal to the radius of the steel ring 3. The steel ring 3 is inserted into the semicircular groove through the steel pipe mounting part 4. Fixed on the big wheel 1, a number of small wheels 2 strung on the steel ring 3 are respectively embedded in the grooves on the periphery of the big wheel 1, the axis of the small wheel 2 is perpendicular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com