Radiator of printed circuit board

A heat dissipation device and circuit board technology, which is applied in the fields of electrical digital data processing, cooling/ventilation/heating transformation, instruments, etc., can solve the problems of increased cost, long distance between the water tank body and the heating chip, and the fact that the water-cooled heat dissipation device cannot meet the requirements of actual use. Need to wait for the problem to achieve the effect of reducing the assembly space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

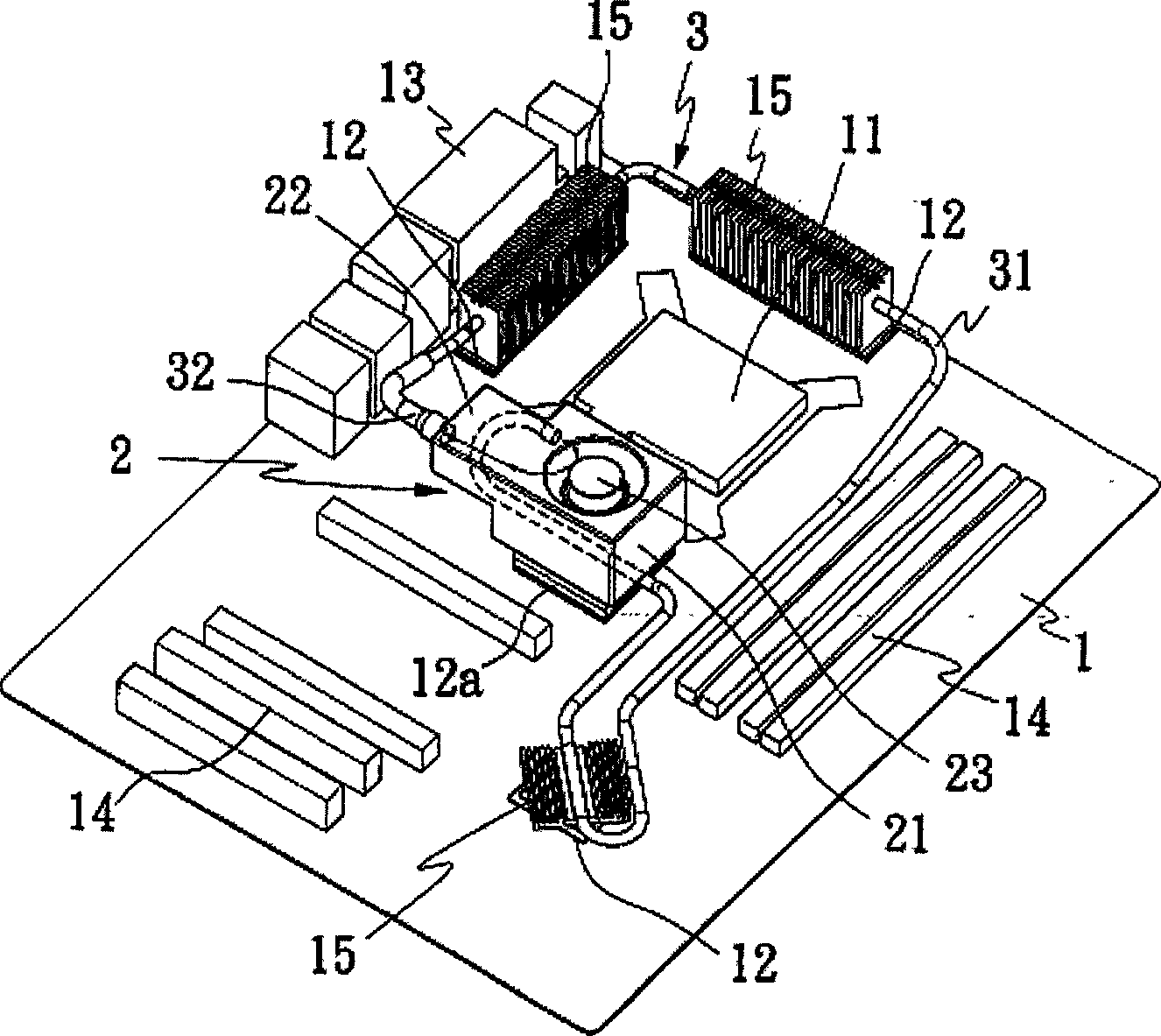

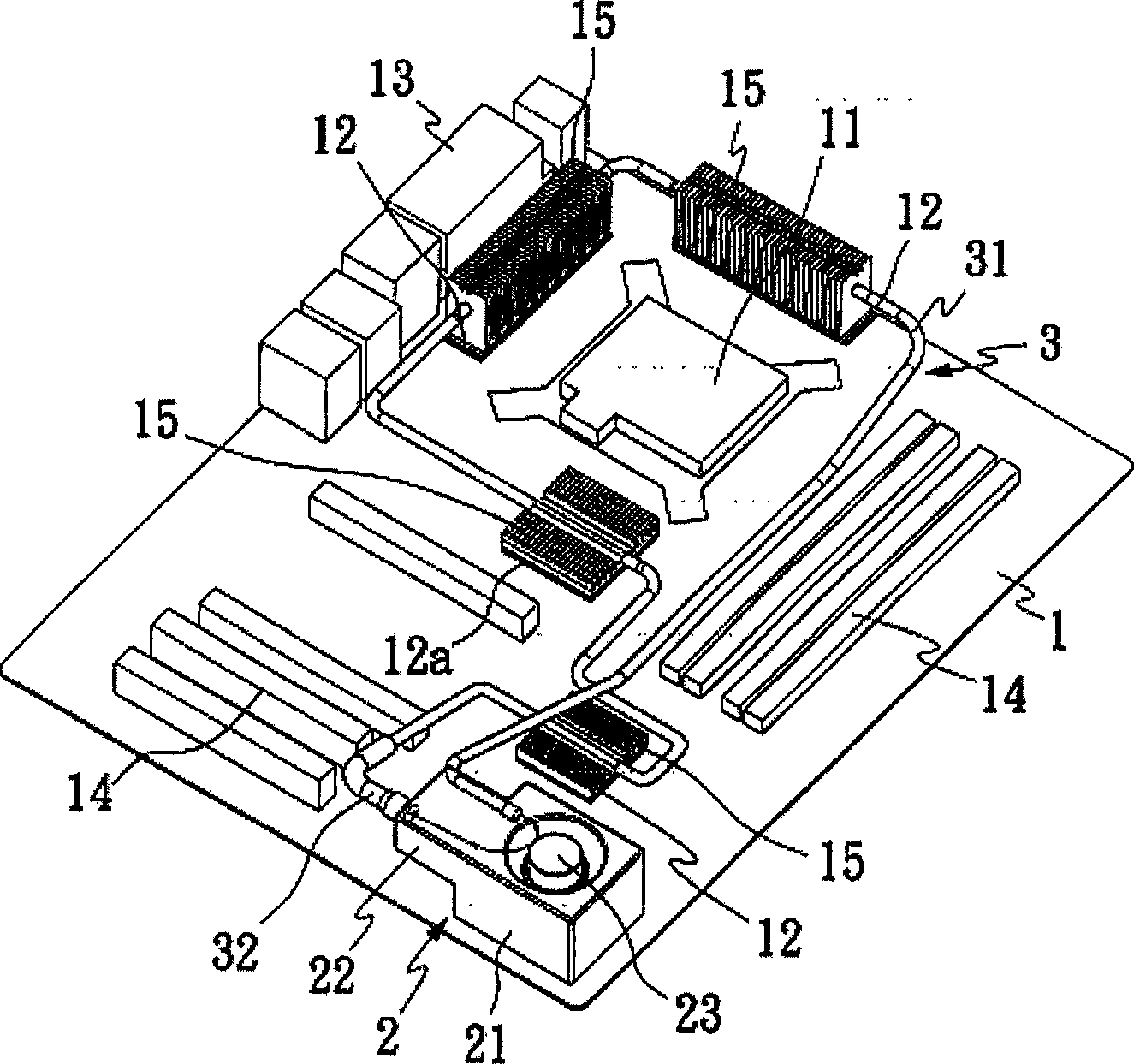

[0023] See attached figure 1 , 2 As shown, the present invention mainly includes a circuit board 1, a circulation mechanism 2 and a flow guide unit 3. The circulation mechanism 2 is arranged at an appropriate place on the circuit board 1, and the flow guide unit 3 is connected to the heat source on the circuit board 1 and communicates with the circulation. The mechanism 2 can reduce the assembly space required by the circulation mechanism 2 and the flow guide unit 3 when the circuit board 1 is arranged in the casing, and the circulation mechanism 2 and the flow guidance unit 3 will not be affected when the casing is disassembled or replaced setting.

[0024] The aforementioned circuit board 1 is provided with a central processing unit 11 , several electronic chips 12 , several connectors 13 and slots 14 , and the electronic chips 12 , 12 a are respectively provided with heat sink groups 15 .

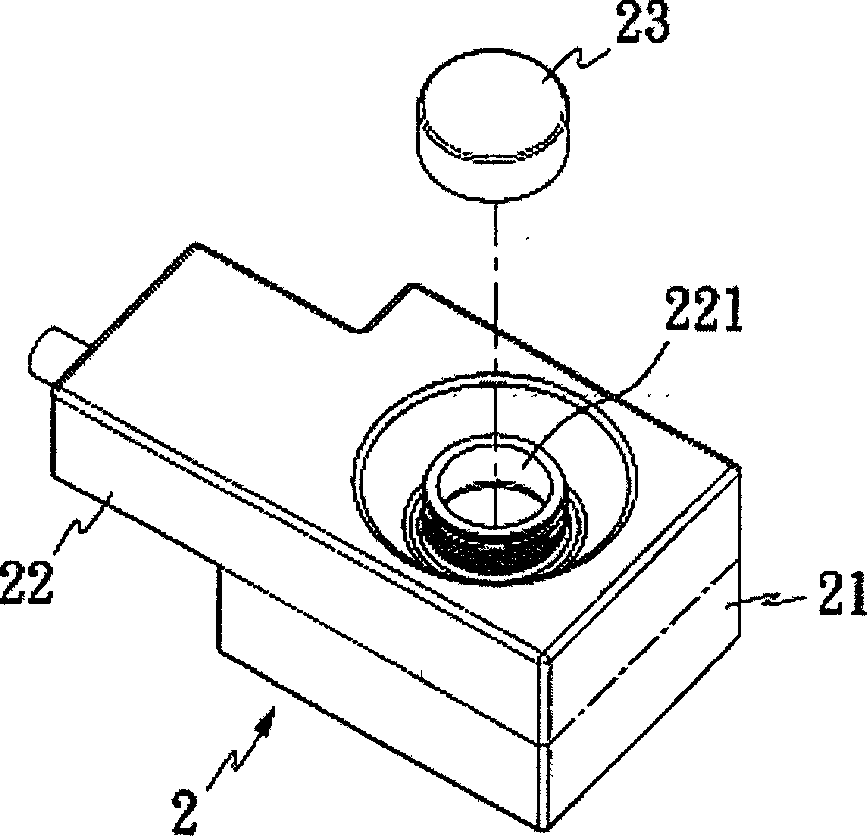

[0025] The circulation mechanism 2 is composed of a brake unit 21 and a storage un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com