Workpiece holder and workpiece transporting clamp

A technology of workpiece holder and workpiece, applied in the field of workpiece holder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

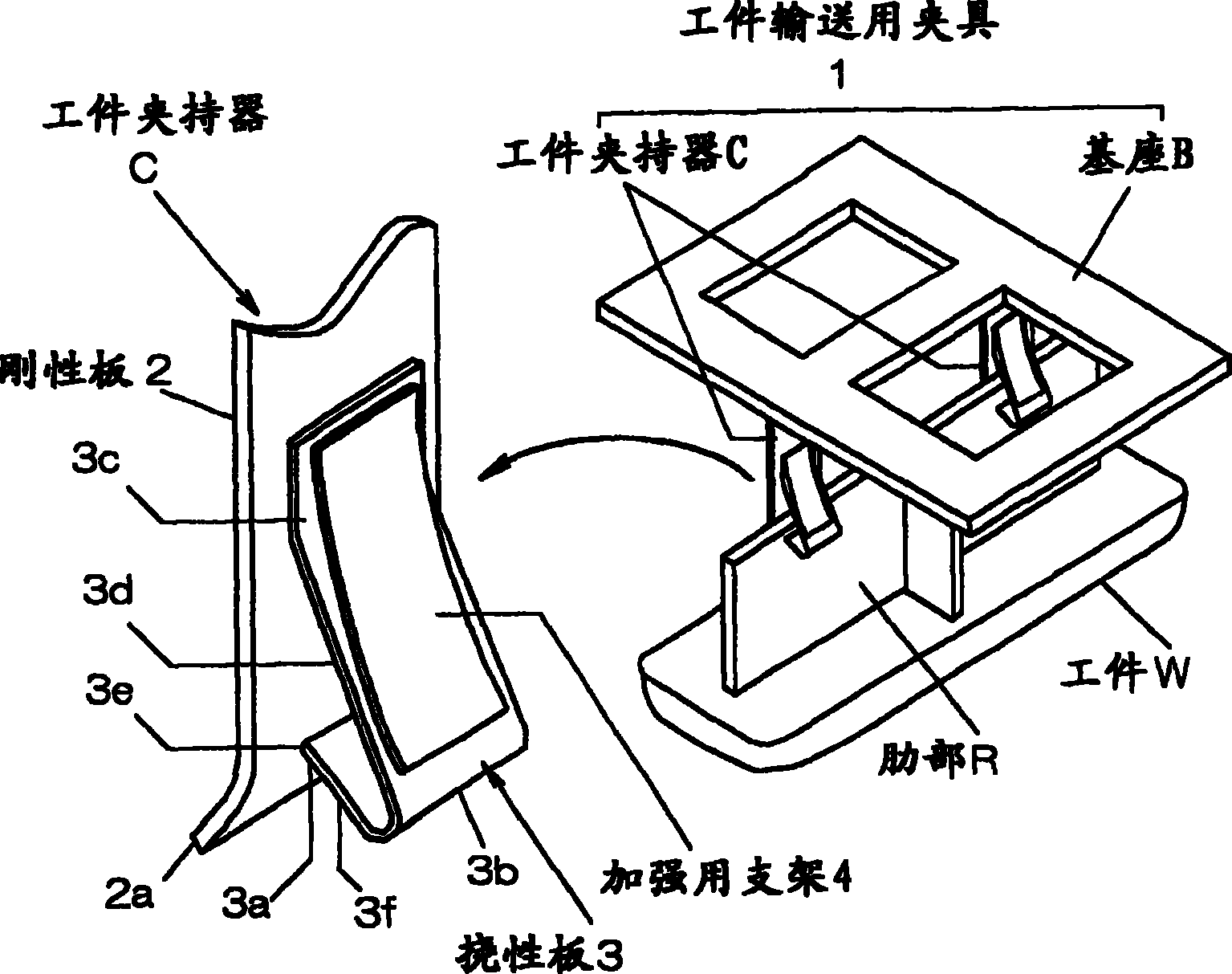

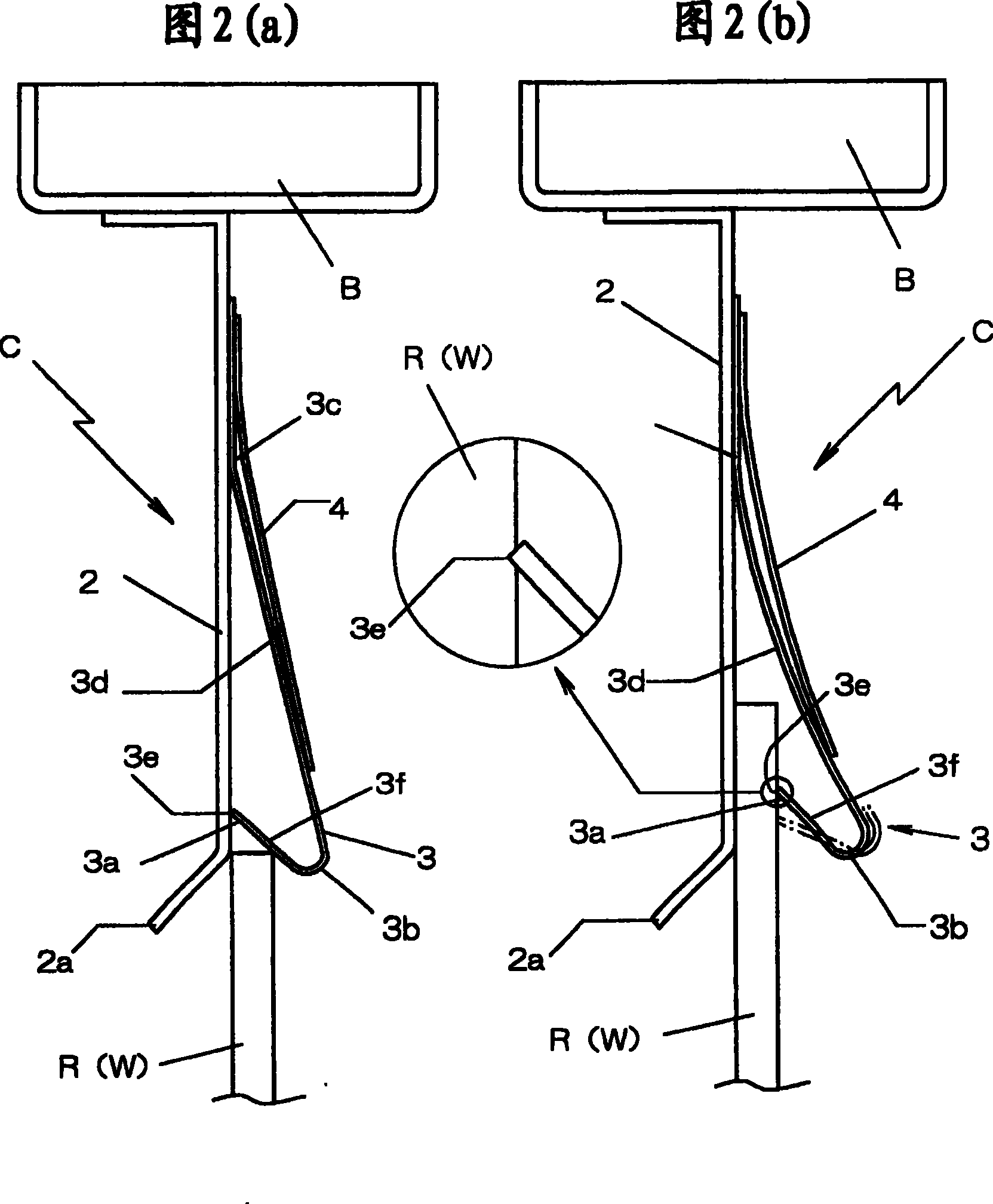

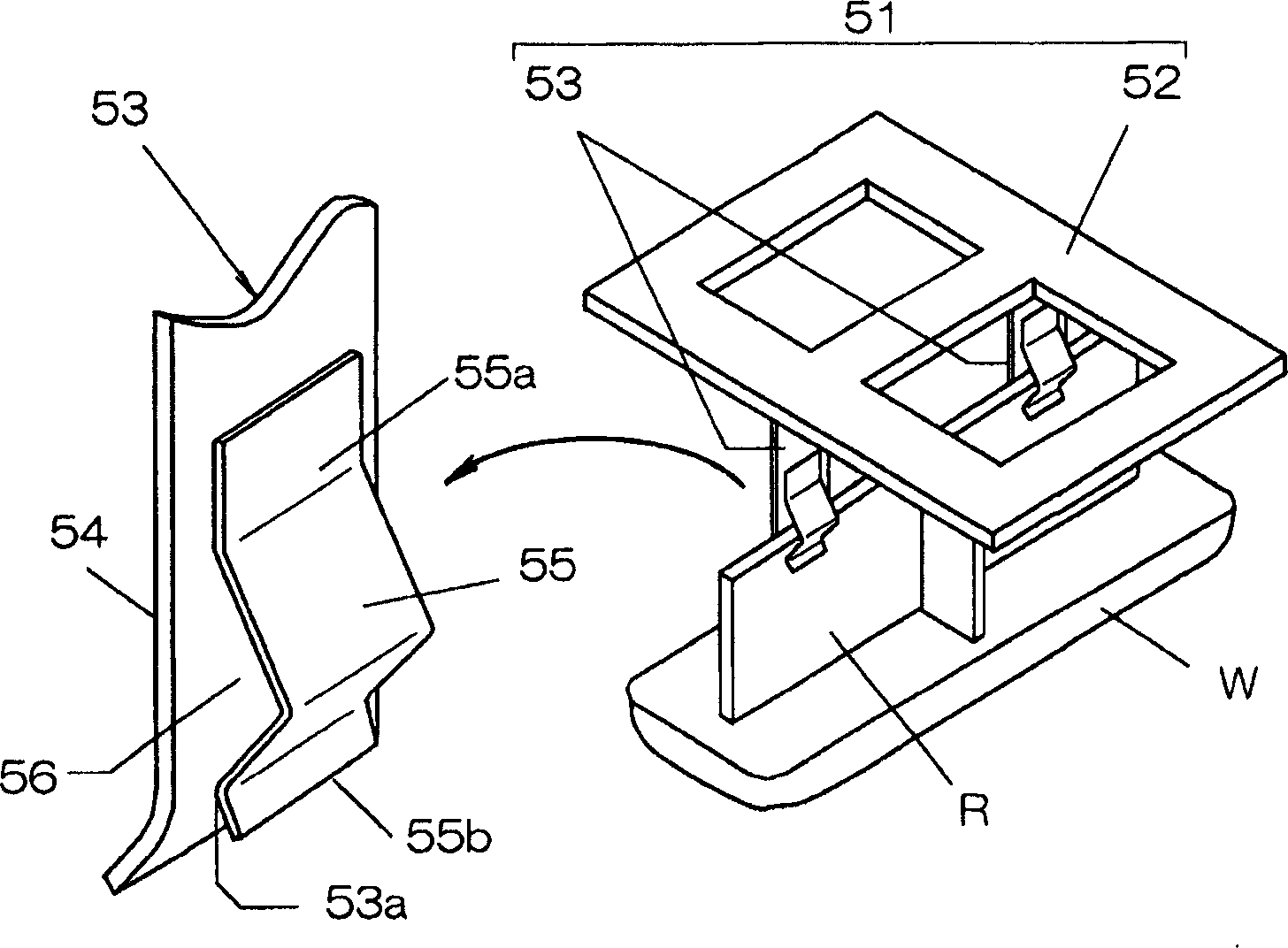

[0029] figure 1 The shown workpiece transport jig 1 holds the ribs R formed on the back side of the workpiece W and transports the workpiece W. Therefore, on the base B transported by a conveyor or a robot (not shown), the Clampers C for clamping the ribs R are attached at positions corresponding to the ribs R at predetermined intervals.

[0030] The workpiece holder C is formed such that one end side of the flexible plate 3 is overlapped and welded and fixed on the rigid plate 2, which is fixed on the base B, and is held by the elastic force of the flexible plate 3 from its free end. The 3a side inserts the workpiece W between the rigid plate 2 and the flexible plate 3 .

[0031] The rigid board 2 uses a metal material with higher bending rigidity (EI value) than the flexible board 3, and even if the same material is used, the rigidity can be increased by selecting a material with a larger thickness and width.

[0032] In addition, the size of the rigid plate 2 varies depe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com