Electrical connecting component comprosing a hotmelt element, method and tool for manufacturing such an electrical component

A technology of electrical components and components, which can be applied to the components of connecting devices, circuit/collector components, electrical components, etc., and can solve problems such as obstacles to development of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

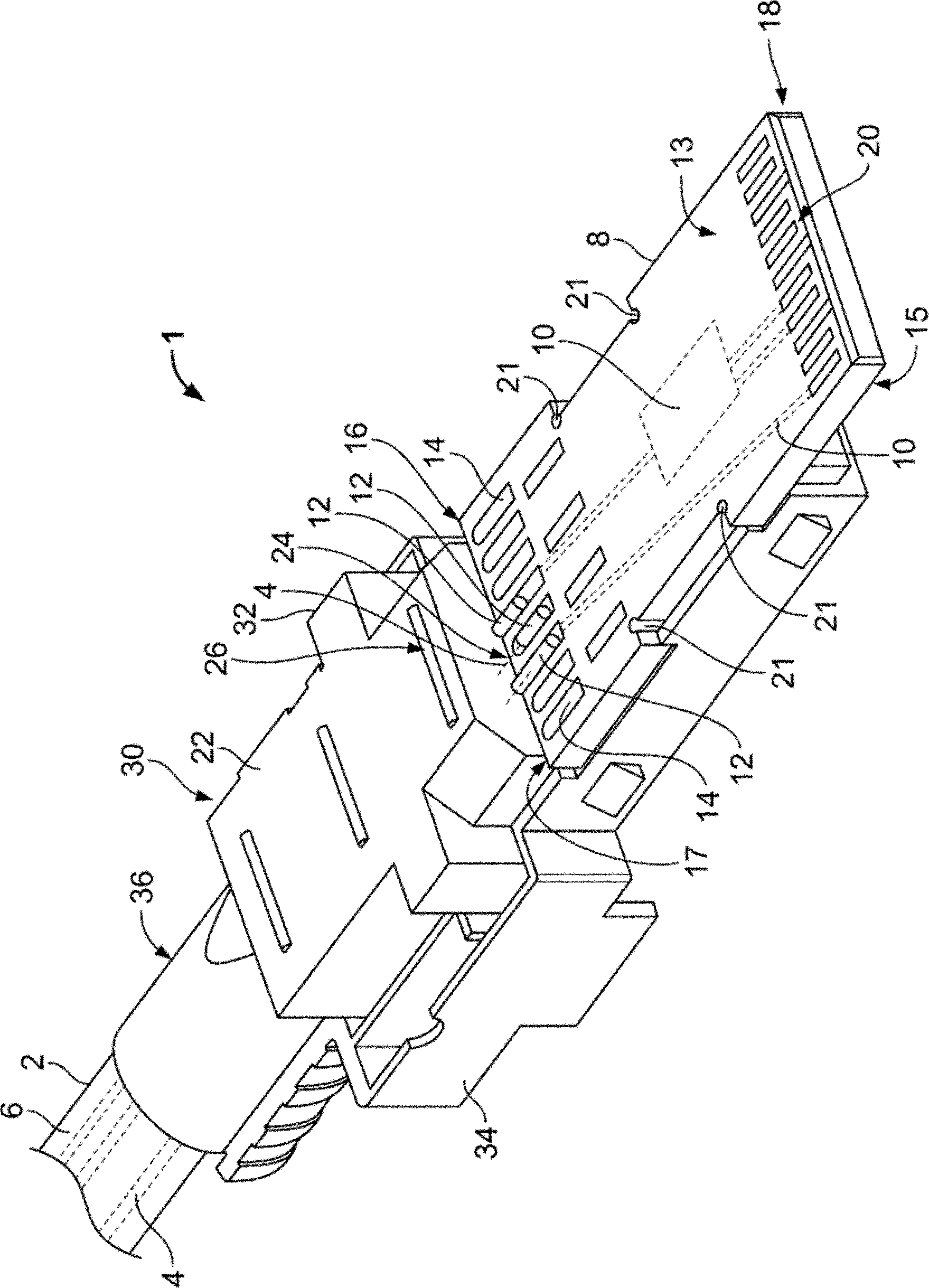

[0039] First, refer to figure 1 The configuration of the electrical component 1 according to the present invention is explained.

[0040] The electrical component 1 comprises at least one cable element and the cable element 2 correspondingly comprises at least one electrically conductive member 4 such as a lead of electrically conductive material. Typically, at least one conductive member is enclosed in an insulating cladding 6 , which also surrounds an electromagnetic shielding layer, not shown, to shield off electromagnetic radiation from the conductive member 4 .

[0041] The cable element 2 is mechanically and electrically connected to the substrate element 8 . The connection can be produced by connecting the at least one electrically conductive component 4 and the at least one electrical component 10 of the substrate element, in particular by means of a solder joint 12 on the upper surface 13 of the substrate element 8 . The number of solder joints 12 corresponds to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com