Electronic ballast, lighting device and method for operating high-pressure discharge lamps

A technology of high-pressure discharge lamps and electronic ballasts, which is applied in the direction of measuring current/voltage, the use of gas discharge lamps, energy-saving lighting, etc., to achieve the effect of uncomplicated evaluation and avoiding technical complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

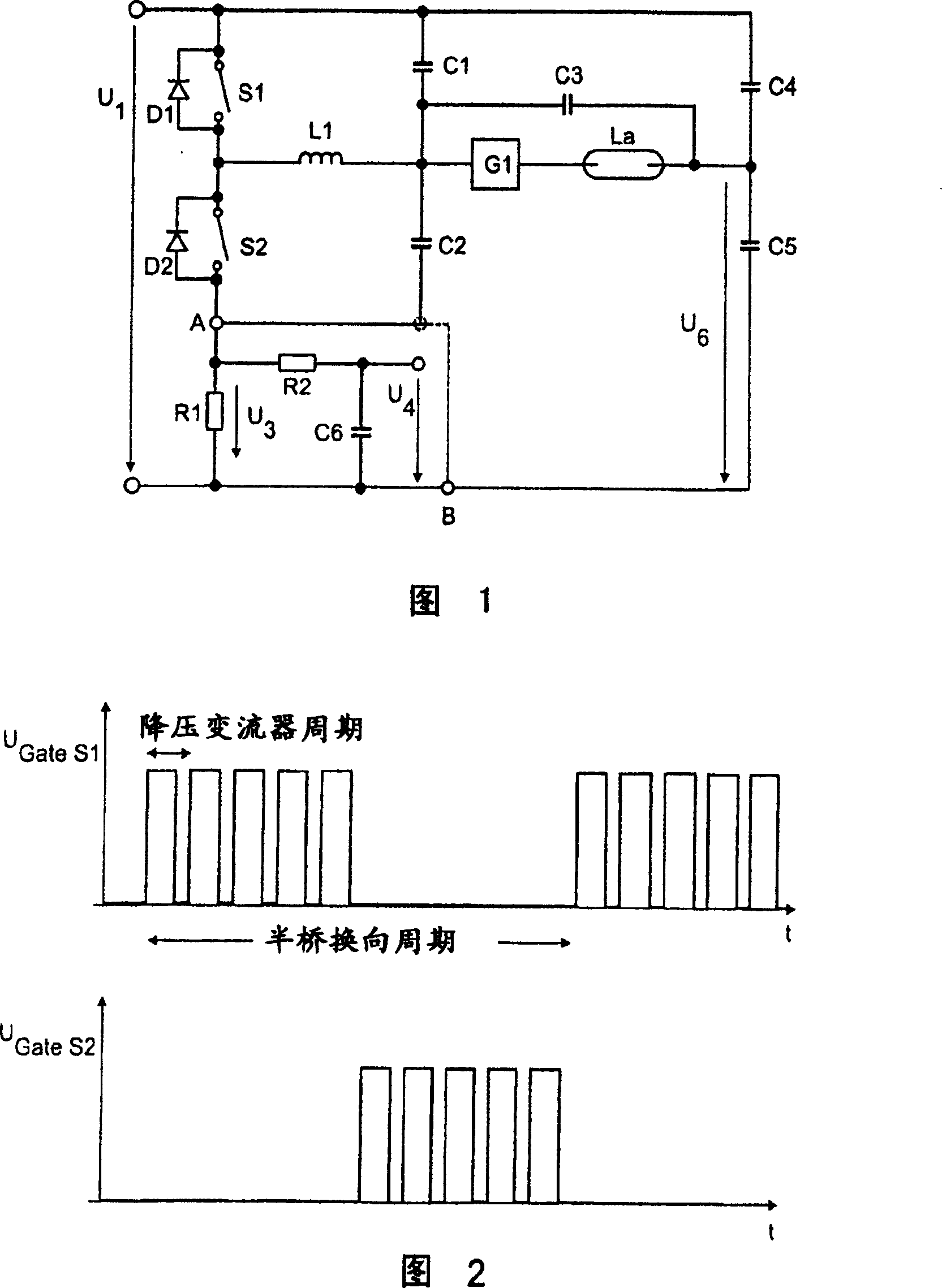

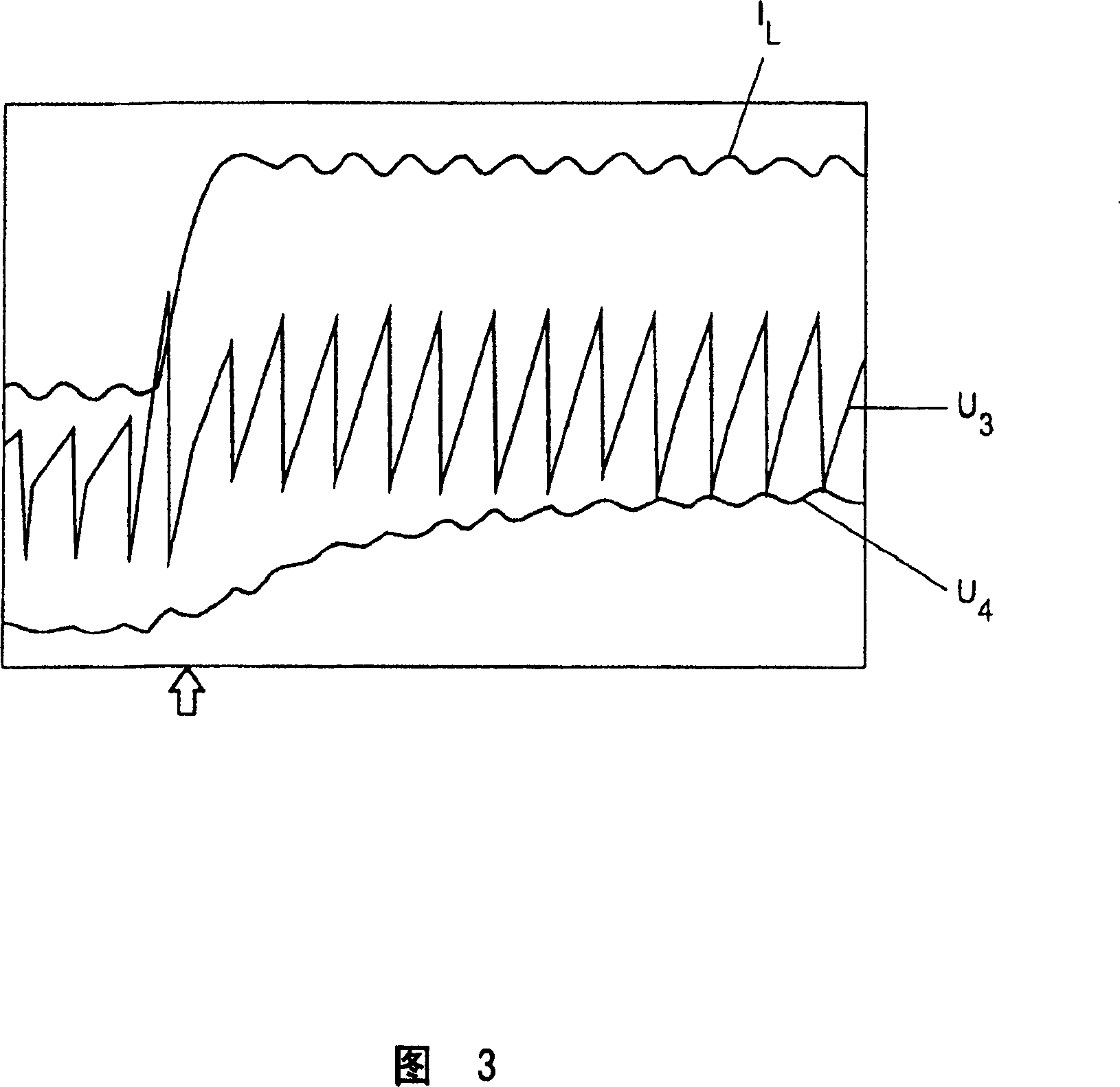

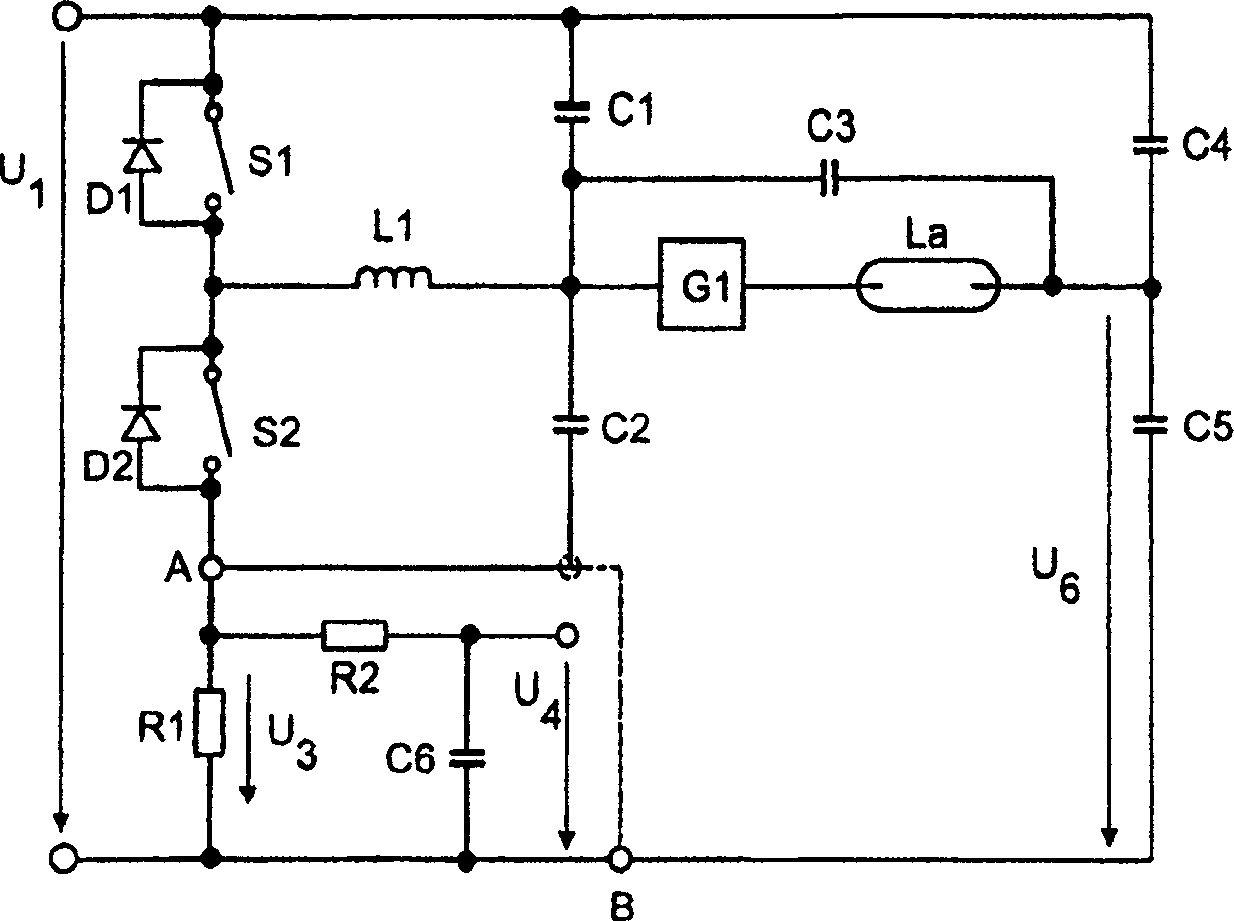

[0021] figure 1 denoted per se well known with two switching transistors S 1 and S 2 Half-bridge topology diagram. The switching transistor S 1 and S 2 Series connection between two supply branches between which the intermediate circuit voltage U is applied 1 . The intermediate circuit voltage U is generated by rectification and corresponding filtering of the system voltage and power factor correction by means of a step-up converter 1 .

[0022] Since the half-bridge transistor S 1 and S 2 The alternating switching operation of the two, the center tap between them switches back and forth between the potentials of the power branches. Accordingly, a high-frequency alternating potential corresponding to this switching operation is applied to figure 1 The inductance L shown 1 left terminal. Inductance L 1 with high pressure discharge lamps, part G 1 connected in series, the inductance L 1 Parts G connected to high-pressure discharge lamps 1 Represents the already w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com