A Method for Determination of Internal Anticorrosion and Anode Protection Spacing for Coated Wells with Casing

A technology for anodic protection and determination methods, which is applied in the field of oil field corrosion and protection, can solve problems such as heavy workload, difficult protection potential, and great difficulty, so as to reduce cycles and times, avoid technical complexity, and make experiments fast and easy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

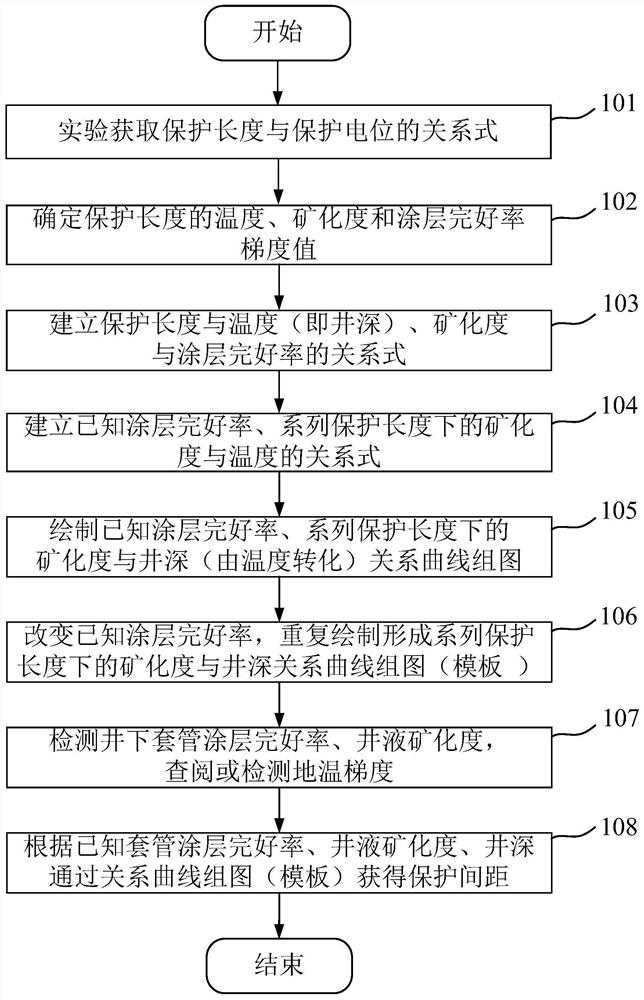

Method used

Image

Examples

Embodiment 1

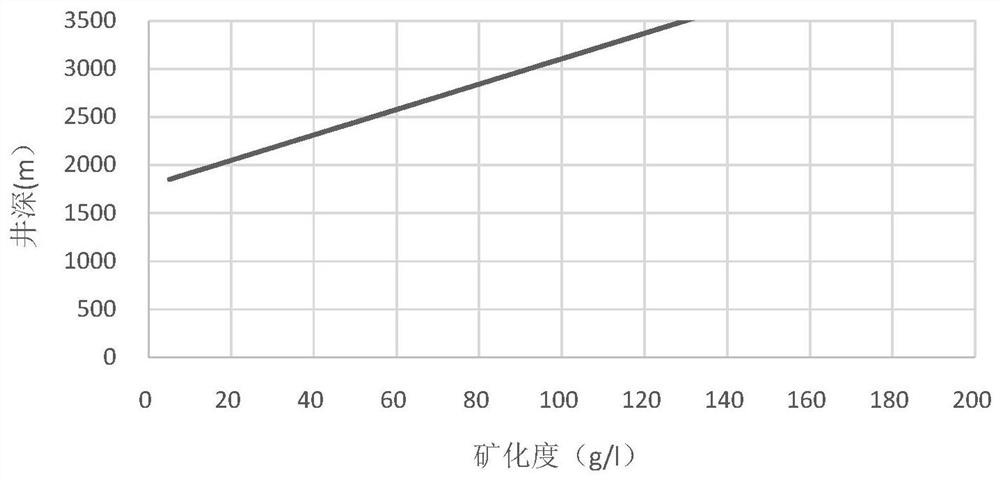

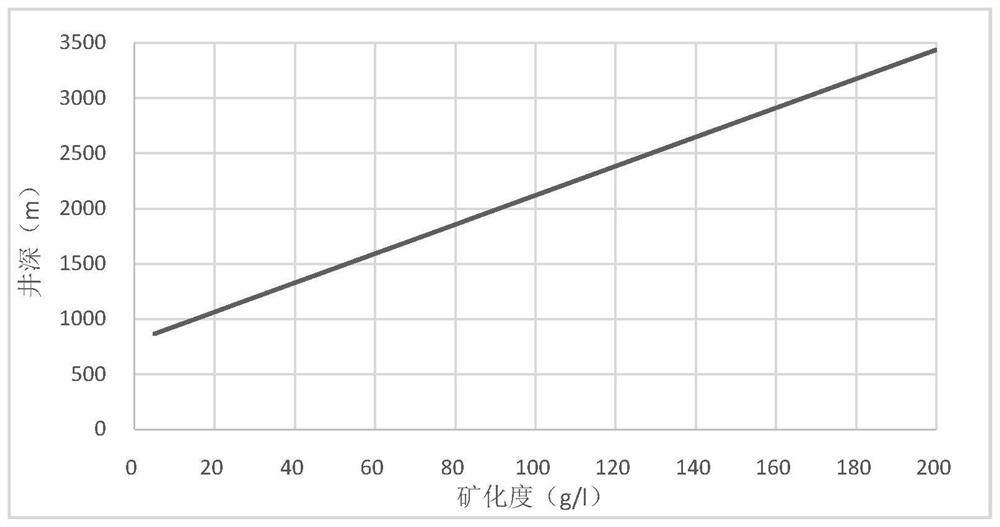

[0074] In a certain area, the wellbore temperature of the oil wells to be anti-corrosion anode inside the casing is about 25 ℃ ~ 55 ℃, and the salinity of the formation water is about 70g / l ~ 30g / l. It is necessary to master the reasonable distribution of the sacrificial anode in the casing, and proceed as follows:

[0075] Step 1: Obtain the relationship between the protection length of the casing material and the protection potential through experiments in a corrosive environment with a certain temperature, salinity and inner coating integrity, that is, the L-U relationship, including the experimental results obtained in four environments The four relational equations, the four environments are the reference temperature (T 基 =28°C) benchmark salinity (M 基 =12g / l) benchmark coating intact rate (C 基 = No coating is 0), high temperature (T 高 =60℃) benchmark salinity (M 基 ) benchmark coating intact rate (C 基 ), base temperature (T 基 ) high salinity (M 高 =78g / l) benchmark ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com