Granulator for producing a granulate made of molten plastic

A granulator and rotor technology, applied in the field of granulators, can solve the problems of large structural complexity of driving motors and templates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

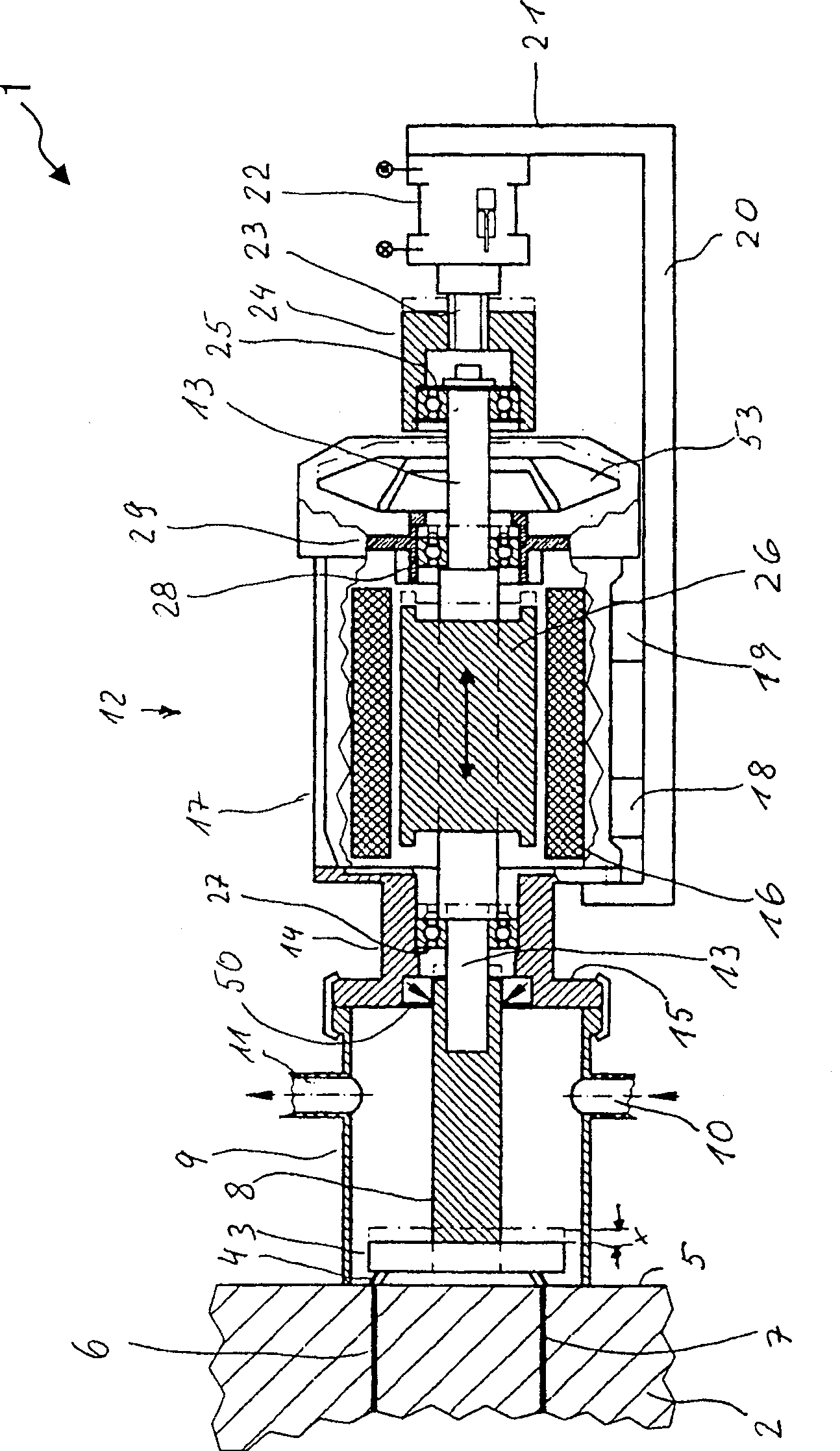

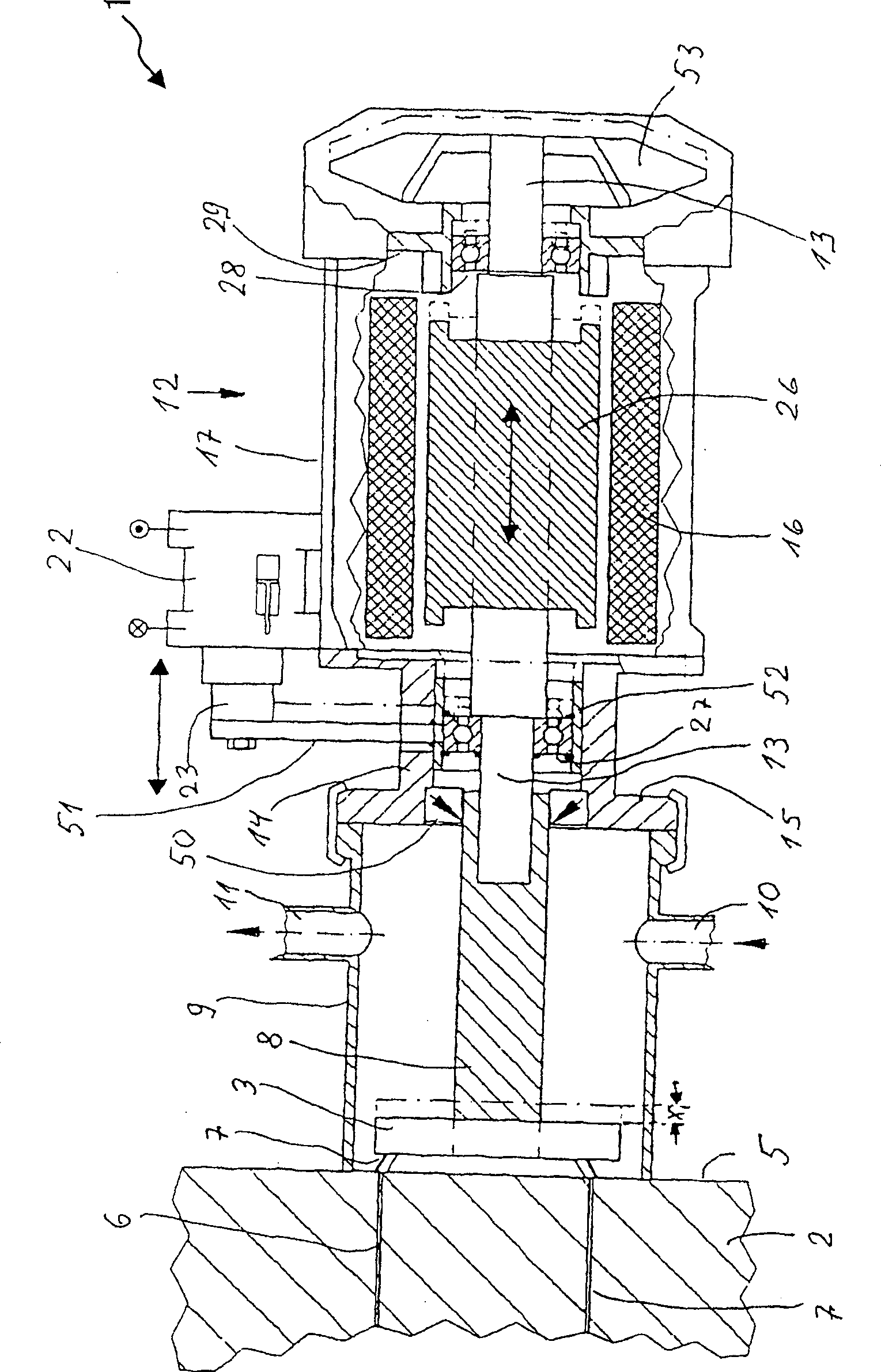

[0016] figure 1 A pelletizer 1 with a template 2 and a rotating cutter head 3 is shown. The cutter 4 of the cutter head 3 sweeps the conveying side 5 of the template 2 and cuts the plastic melt emerging from the nozzles 6 and 7 to form particles. The template 2 contains a large number of annularly arranged nozzles 6 and 7, wherein the large number of nozzles 6 and 7 are figure 1 The middle is not visible. This design is a well-known structure.

[0017] The rotor shaft 8 rotates the cutter head 3, wherein the rotor shaft 8 is housed in the housing 9 together with the cutter head 3 and the cutter 4, and the housing 9 is subjected to a throughflow of a cooling medium, which flows into the inlet 10 and out through the outlet 11, the cooling liquid takes away the particles that have been cut by the cutter 4 and transports the particles to the outside of the housing 9. The housing 9 is fixedly connected to the template 2.

[0018] The rotor shaft 8 is connected to the drive shaft 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com