Press machine frame

A technology of presses and frames, applied in the directions of presses, engine frames, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

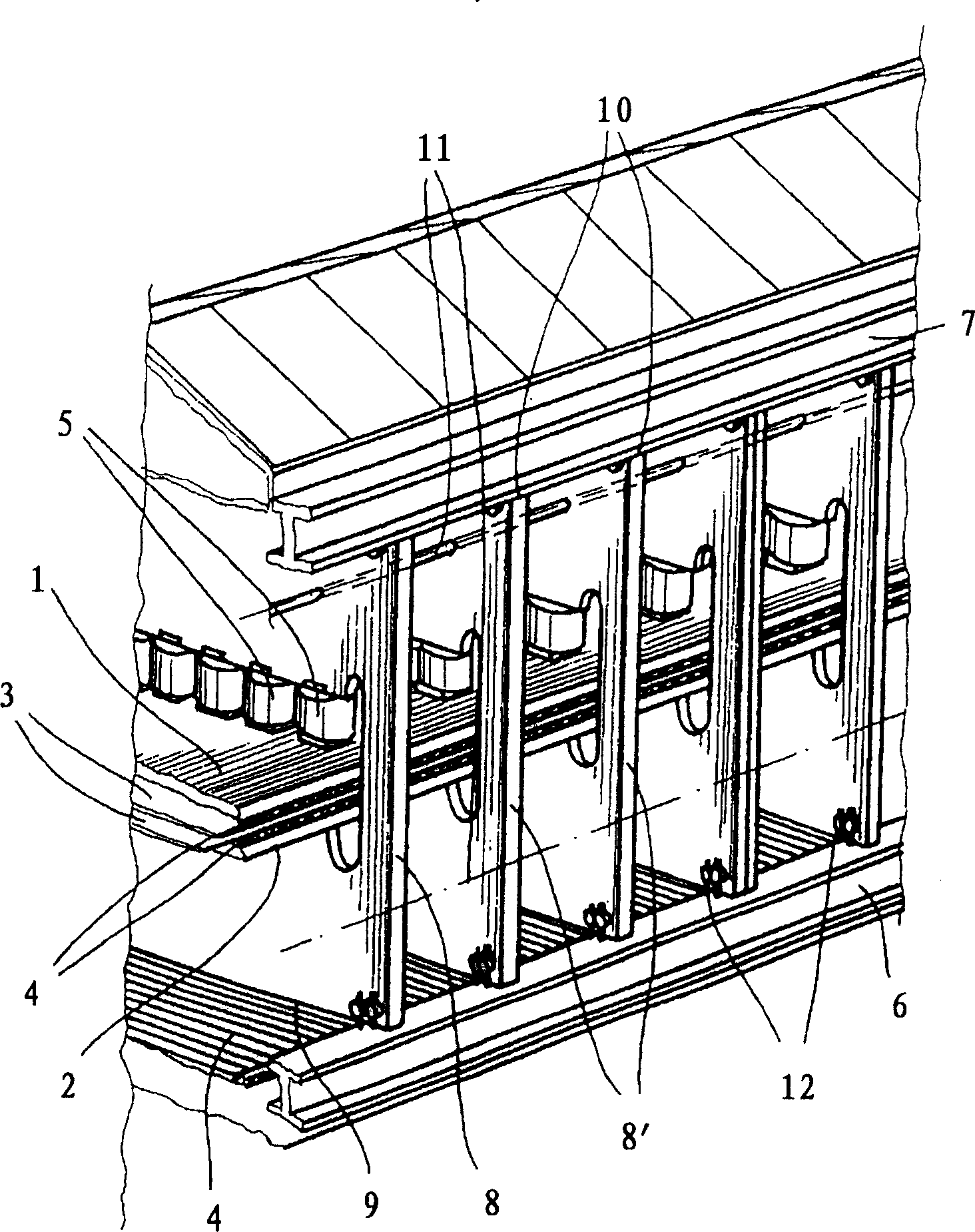

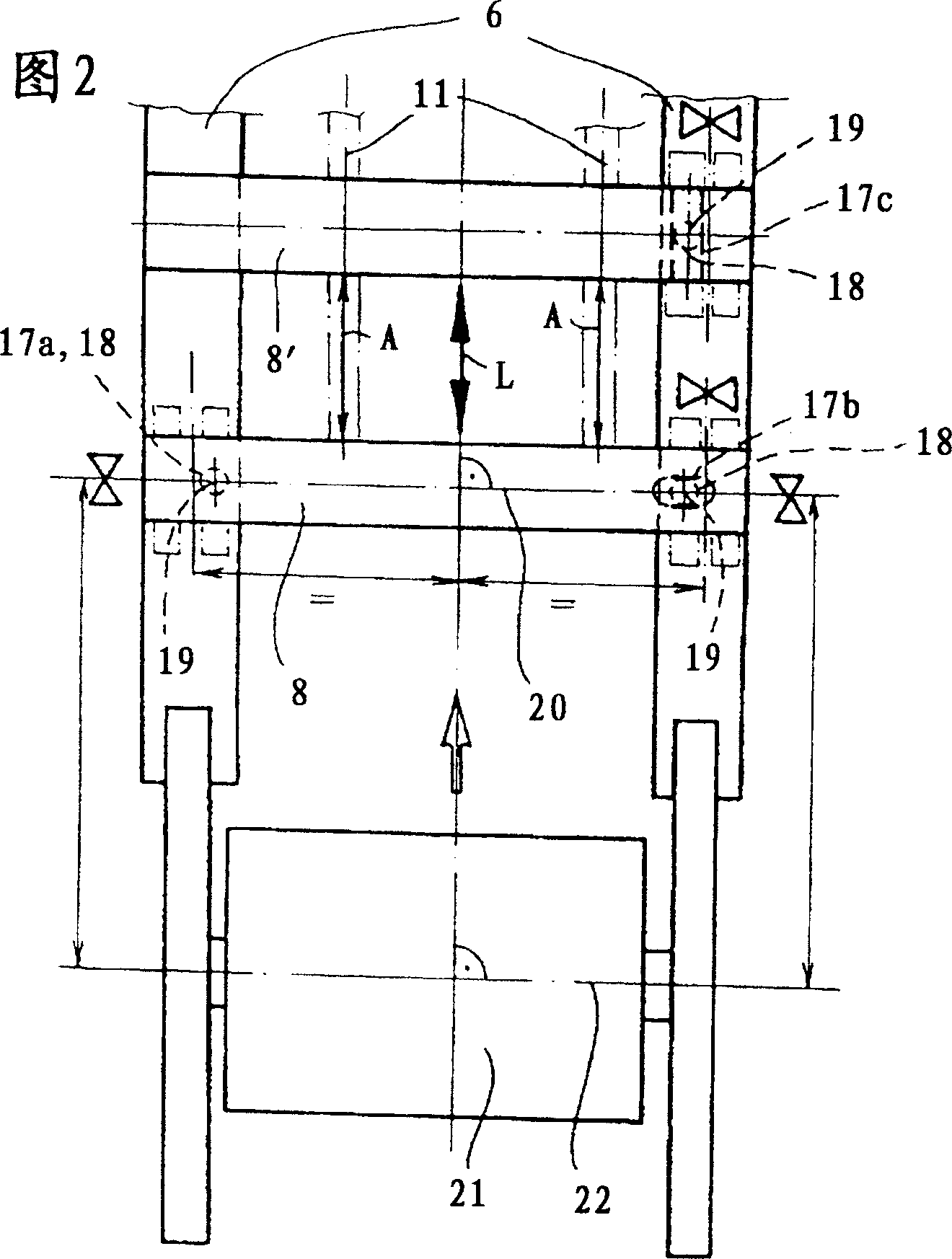

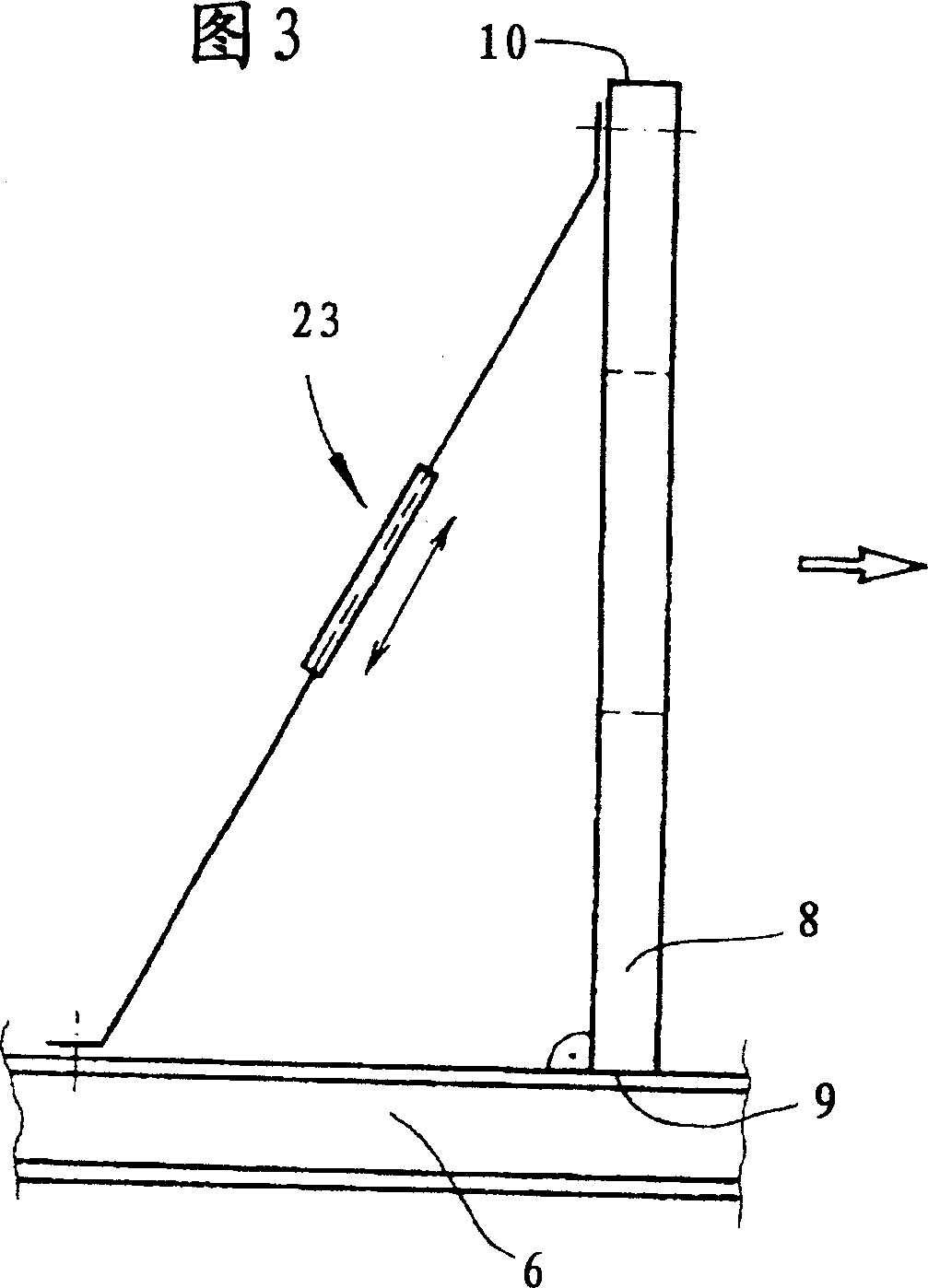

[0022] The drawing shows a press frame for a continuous press for pressing mats of pressed material into pressed material boards, in particular wood boards such as fibreboards, chipboards or the like. figure 1 shows the main structure of one such continuous press. A heatable upper press platen 1 is arranged in a press upper part and a heatable lower press platen 2 is arranged in a press lower part. Furthermore, in the upper part of the press and in the lower part of the press, a continuously running steel pressing belt 3 is guided, which is supported with roller bars 4 interposed against the heatable press plates 1 , 2 . The forces are transmitted into the product to be pressed by means of a cylinder-piston system 5 which is connected at one end to the upper platen 1 and at the other end is supported on the press frame 8, 8'.

[0023]The press frame mainly includes two lower longitudinal supports or longitudinal beams 6 arranged parallel to each other and extending in the lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com