Hydraulic gate connection plate assembling and disassembling device

A technology of hydraulic gate and connecting plate, applied in water conservancy engineering, marine engineering, coastline protection and other directions, can solve the problems of smashing people's feet, waste of manpower, etc., and achieve the effect of reducing the waste of manpower and facilitating installation and dismantling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

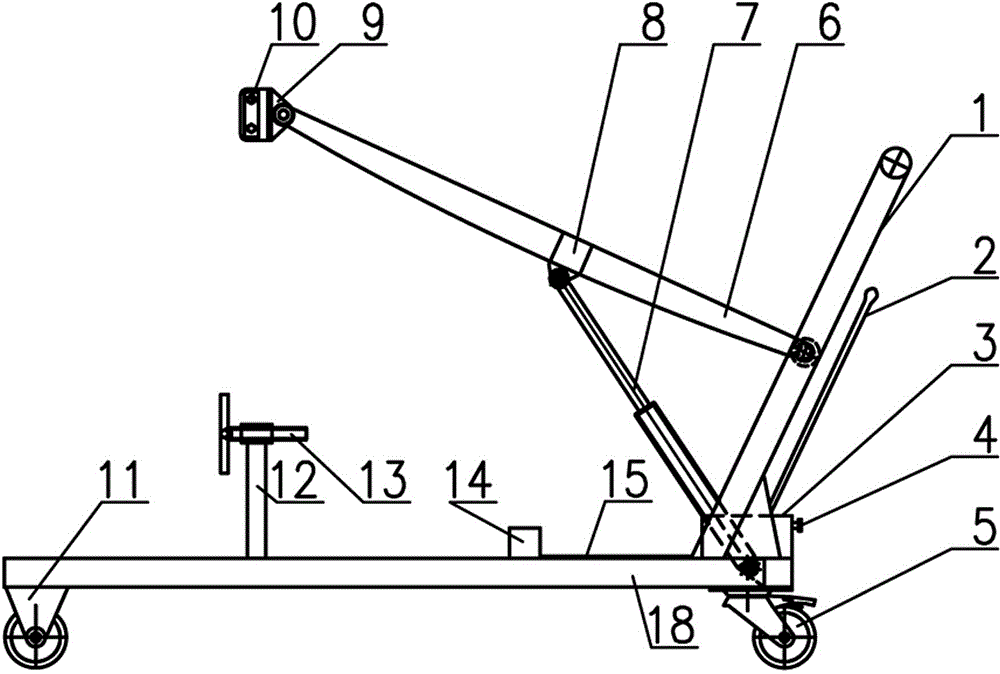

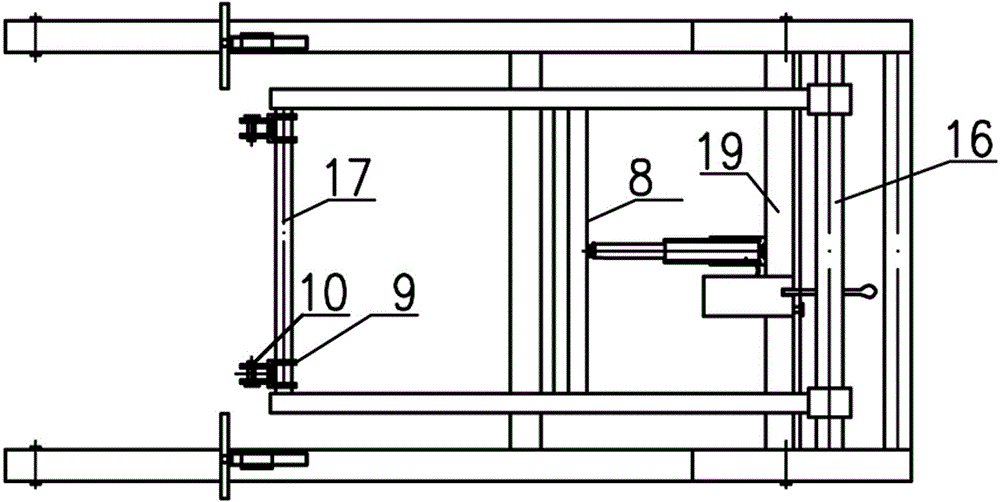

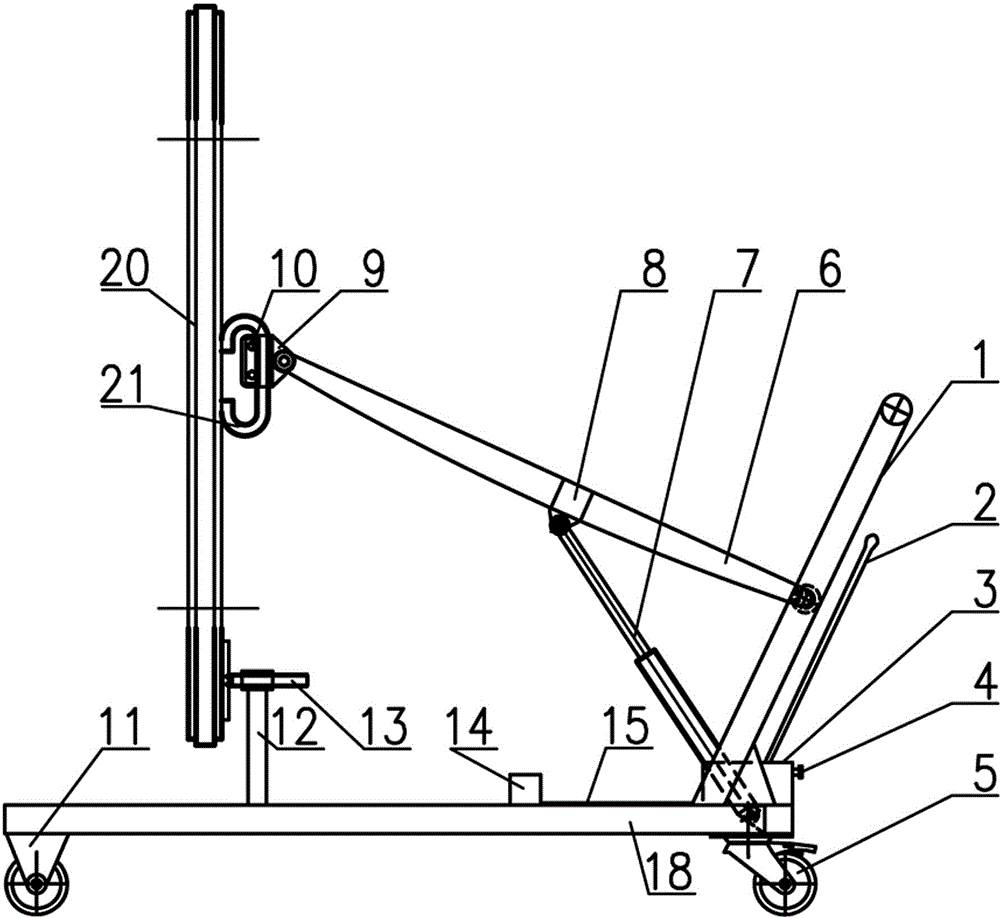

[0018] exist figure 1 and figure 2 Among them, the handlebar 1 is equipped with a support arm rotation shaft 16, the handlebar 1 is connected with the bottom longitudinal beam 18, the bottom tail beam 19 two ends are connected with the bottom longitudinal beam 18, and the bottom middle beam 14 is connected with the bottom longitudinal beam 18. Lay base plate 15 between bottom end beam 19 and bottom middle beam 14, have hole on the base plate 15, reserve rotation space for hydraulic oil cylinder 7. Front-wheel 11 is installed on the front portion of bottom longitudinal beam 18, and universal wheel 5 is installed on bottom longitudinal beam 18 afterbody. One end of the rotating arm 6 is connected with the rotating shaft 16 of the supporting arm, and the rotating arm 6 can rotate around the rotating shaft 16 of the supporting arm. Connecting ears 9 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com