Screen type dust cleaner for coarse particles and dust

A technology of dust collectors and grid screens, which is applied in earth moving machines/excavators, water conservancy projects, artificial waterways, etc., can solve the problems of increased equipment costs, small treatment tanks, etc., and achieves improved opening ratio, deformation prevention, and easy interaction The effect of changing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

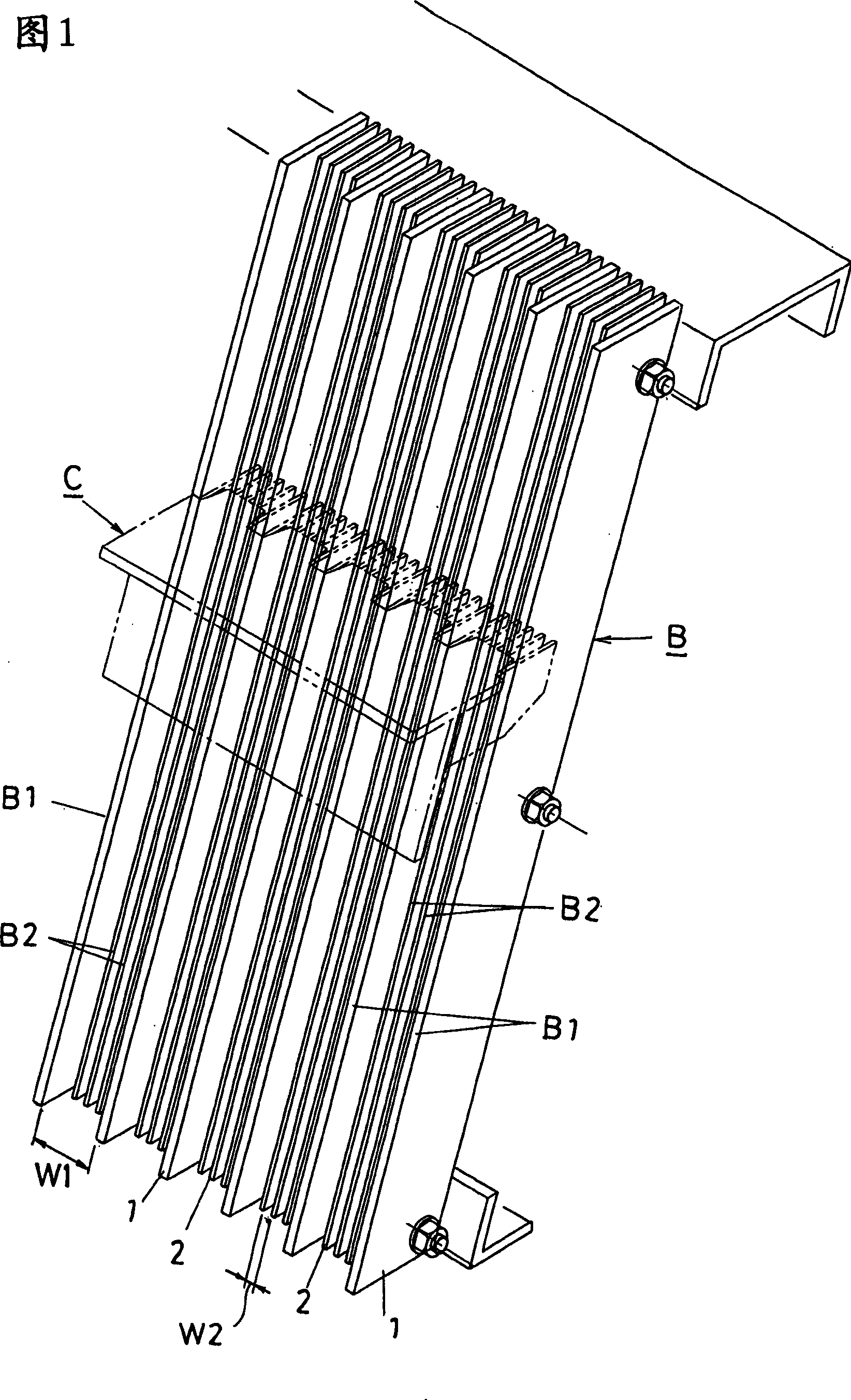

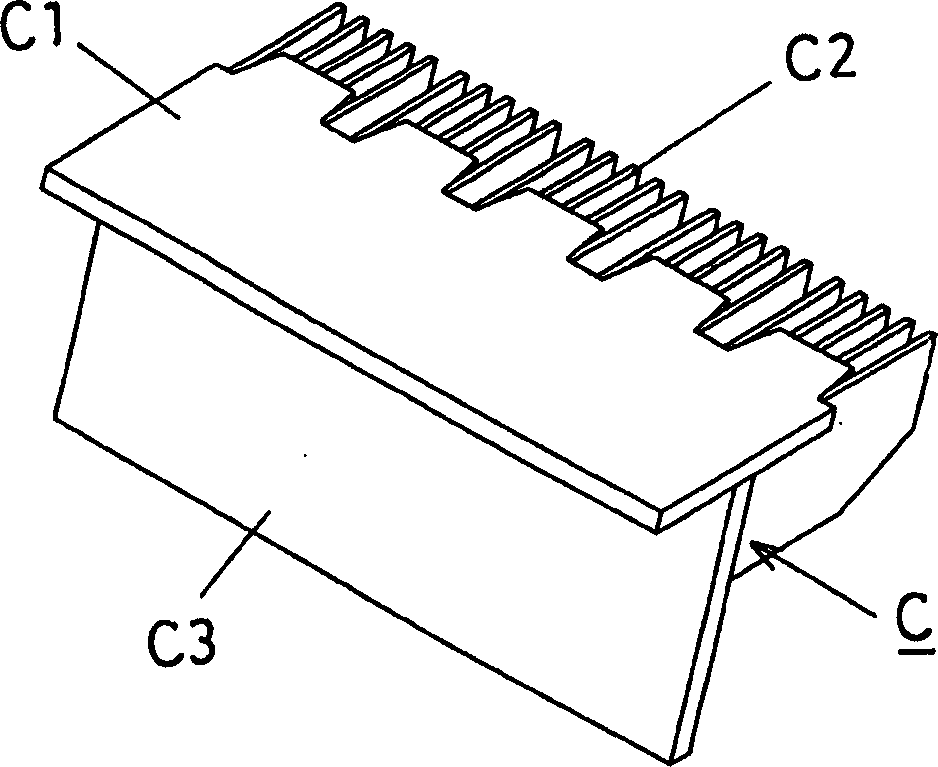

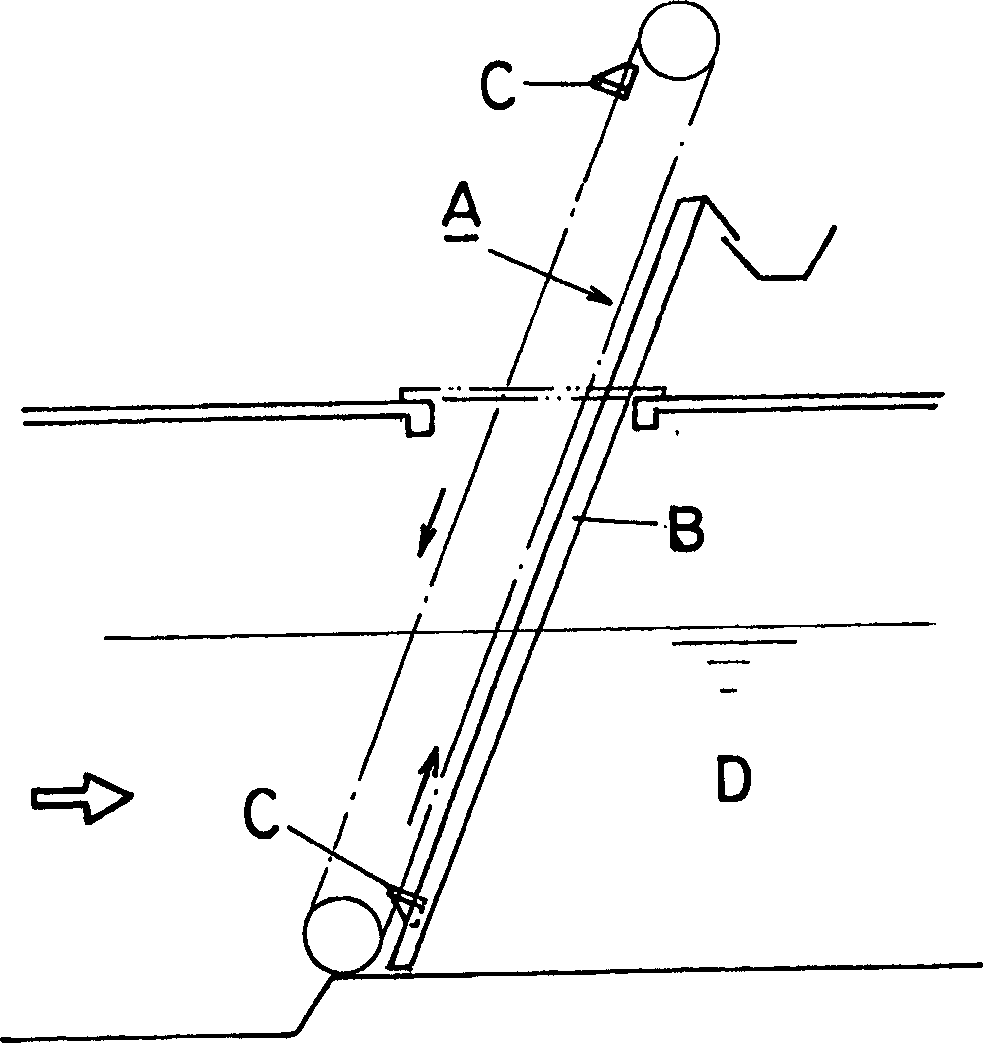

[0025] Figure 1~ image 3 An embodiment of the coarse and fine dust dual-purpose grid-screen dust collector of the present invention is shown.

[0026] When carrying out sewage or drainage treatment at a sewage treatment site or a river drainage treatment site, in order to remove the garbage contained in the treated sewage or drainage, although there is no particular limitation, in this embodiment, for example, image 3 Screen dust collector A was used as shown.

[0027] The grid-type dust collector A is composed of a grid screen B and a rake C, and the grid screen B is arranged so as to block a part of the water flow channel D provided in the treatment tank, and the garbage in the water flow is captured and removed, so that The rake C is arranged so as to move up and down while meshing with the grid intervals of the grid screen B, and the rake C is used to comb and discharge the garbage (residue) caught by the grid screen B.

[0028] In addition, the grid B of this grid typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com