Improved variable condenser

A capacitor and an improved technology, applied in the field of improved variable capacitors, can solve the problems of complex structure of the pre-setting plate, interfering with electrical signals, easy sliding of the fixed plate and moving plate, etc. And the effect of beating noise and ideal electric capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

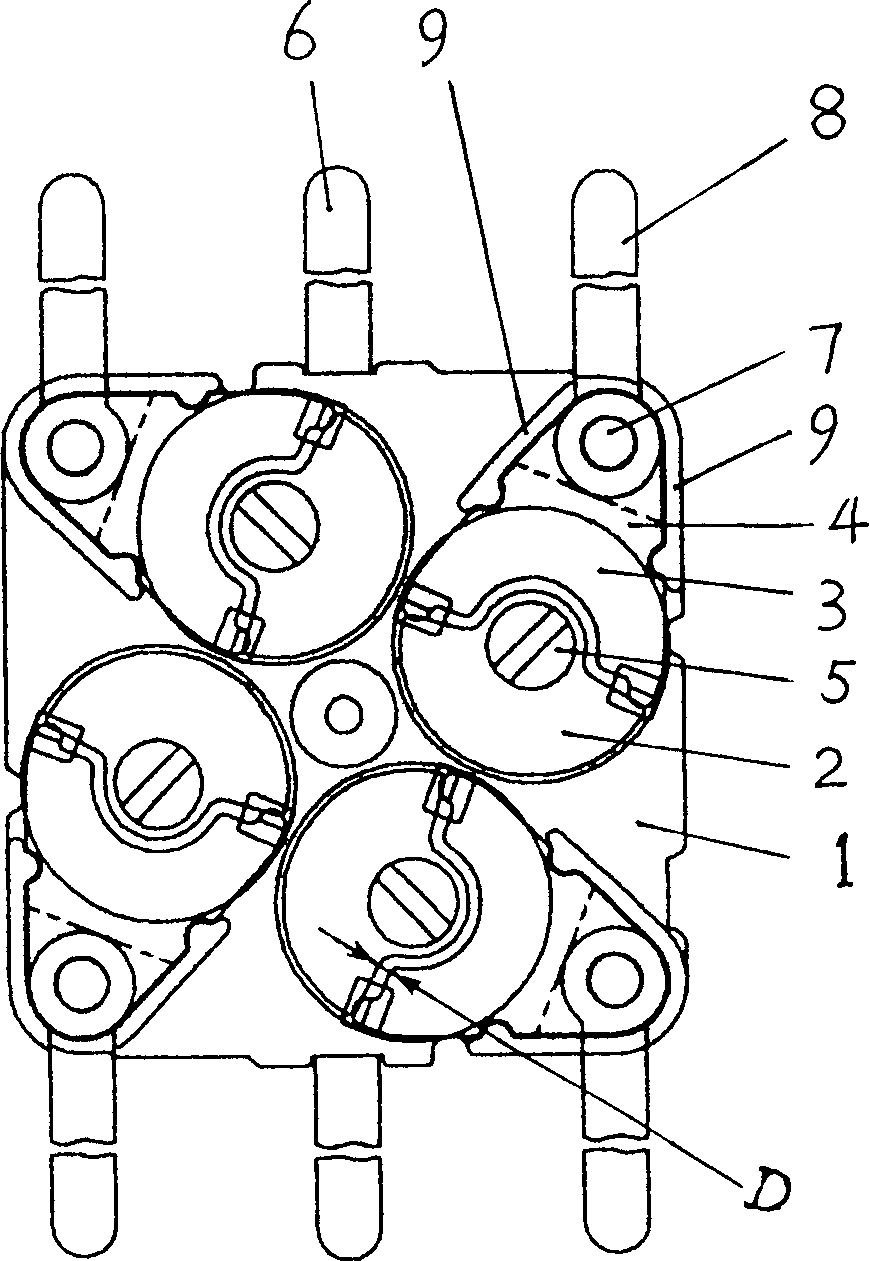

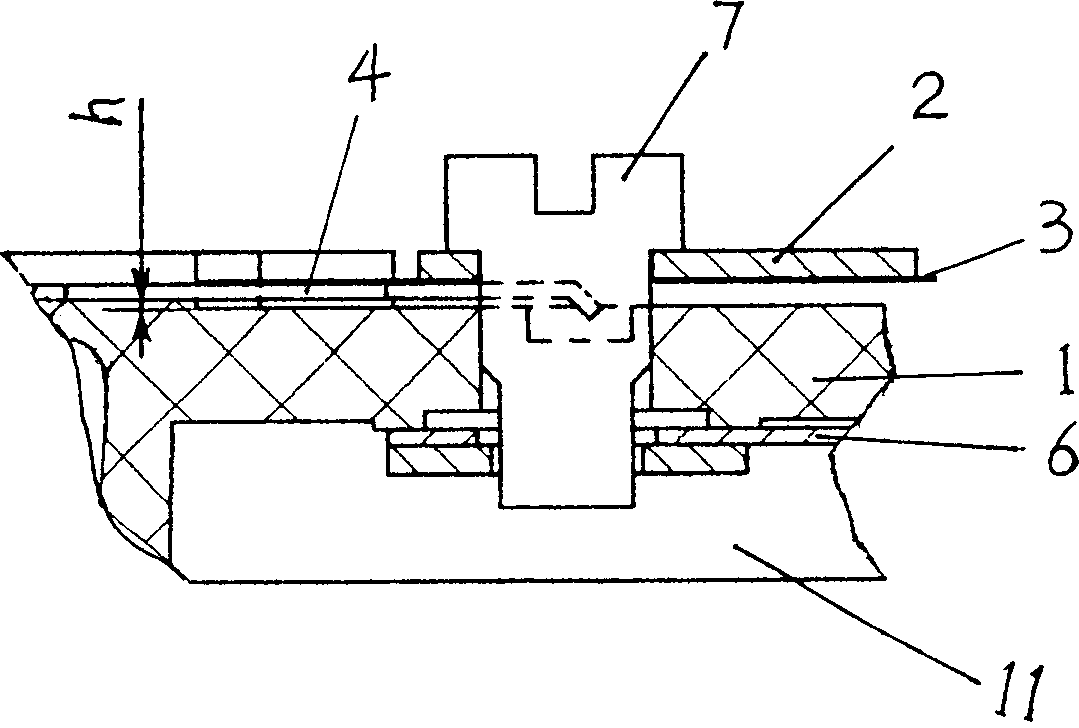

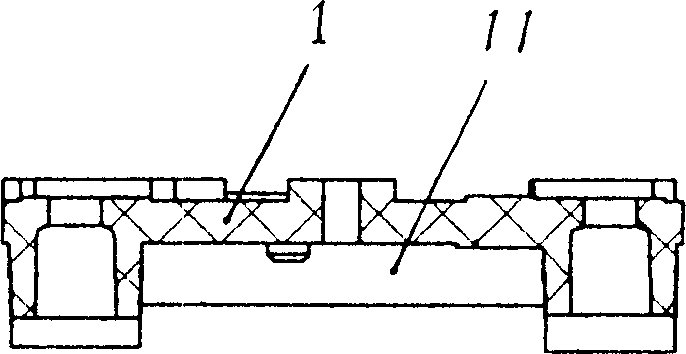

[0021] With reference to the accompanying drawings, it can be seen that the variable capacitor of the present invention is composed of a main adjustment part and a preset adjustment part. 5. For the pre-adjusted grounding lug 6, fasteners 7, and welding lug 8, refer to the attached image 3 , 4 , 5, a positioning rib 9 is designed on the cover plate 1, and a fan-shaped step 10 for installing the preset piece 4 is also designed on the cover plate, and the through hole 13 of the fan-shaped preset piece 4 is located at the center of the fan. The semicircular groove 14 of the fan-shaped presetter is located at the other end corresponding to the through hole, the two ends of the chord side of the fan-shaped presetter are designed with small bends 15, and the cover plate is designed with a pit for embedding the small bends 12. Ribs (or bars) 11 are additionally provided on the inner side of the cover plate.

[0022] The above-mentioned components of the present invention can be pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com