Image data generation method and element installation apparatus using the same

A technology of image data and components, applied in the field of image data generation and component mounting devices using the same, can solve problems such as dissatisfaction and price increases of component mounting devices, and achieve the effect of avoiding cost increases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

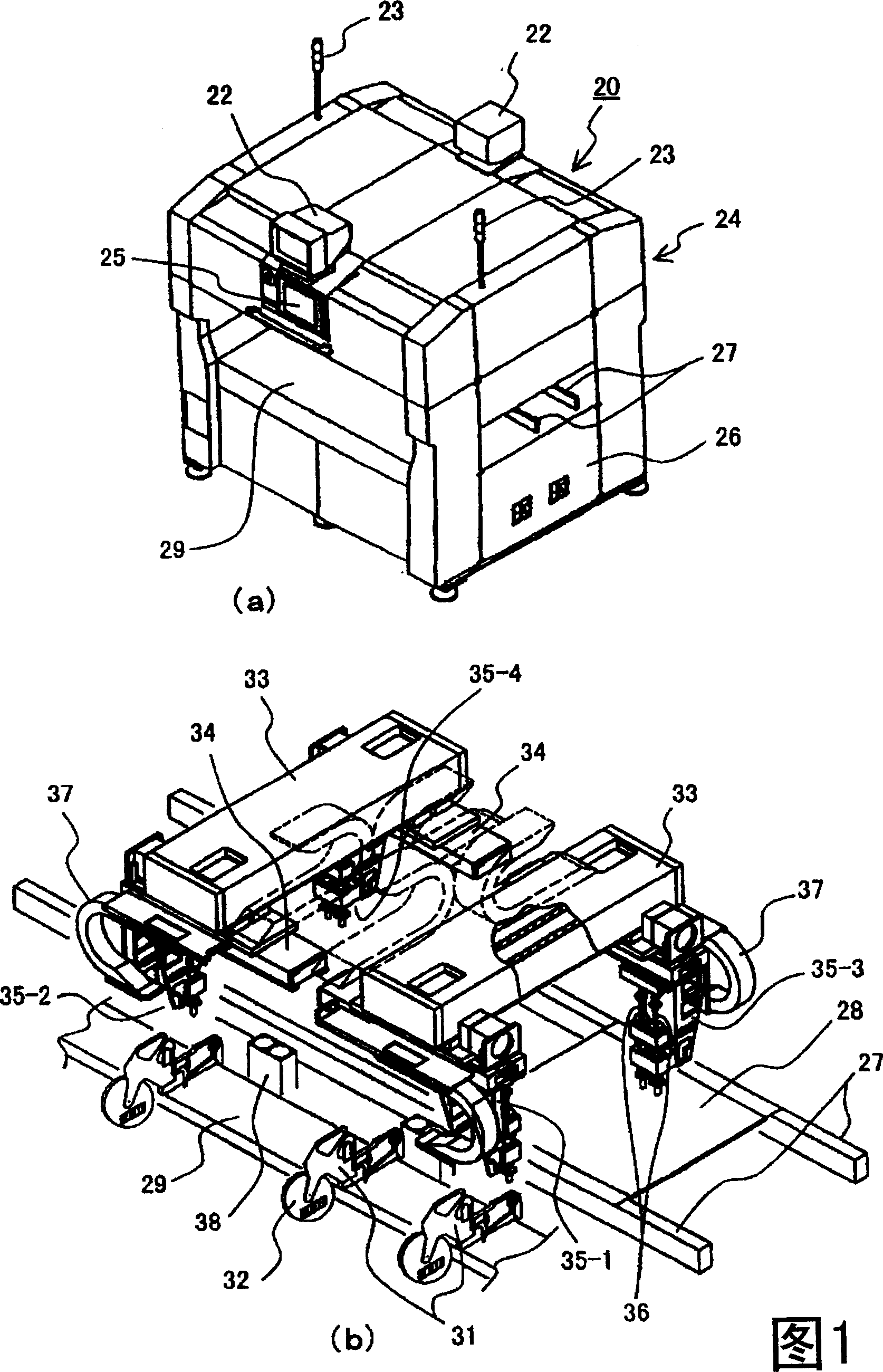

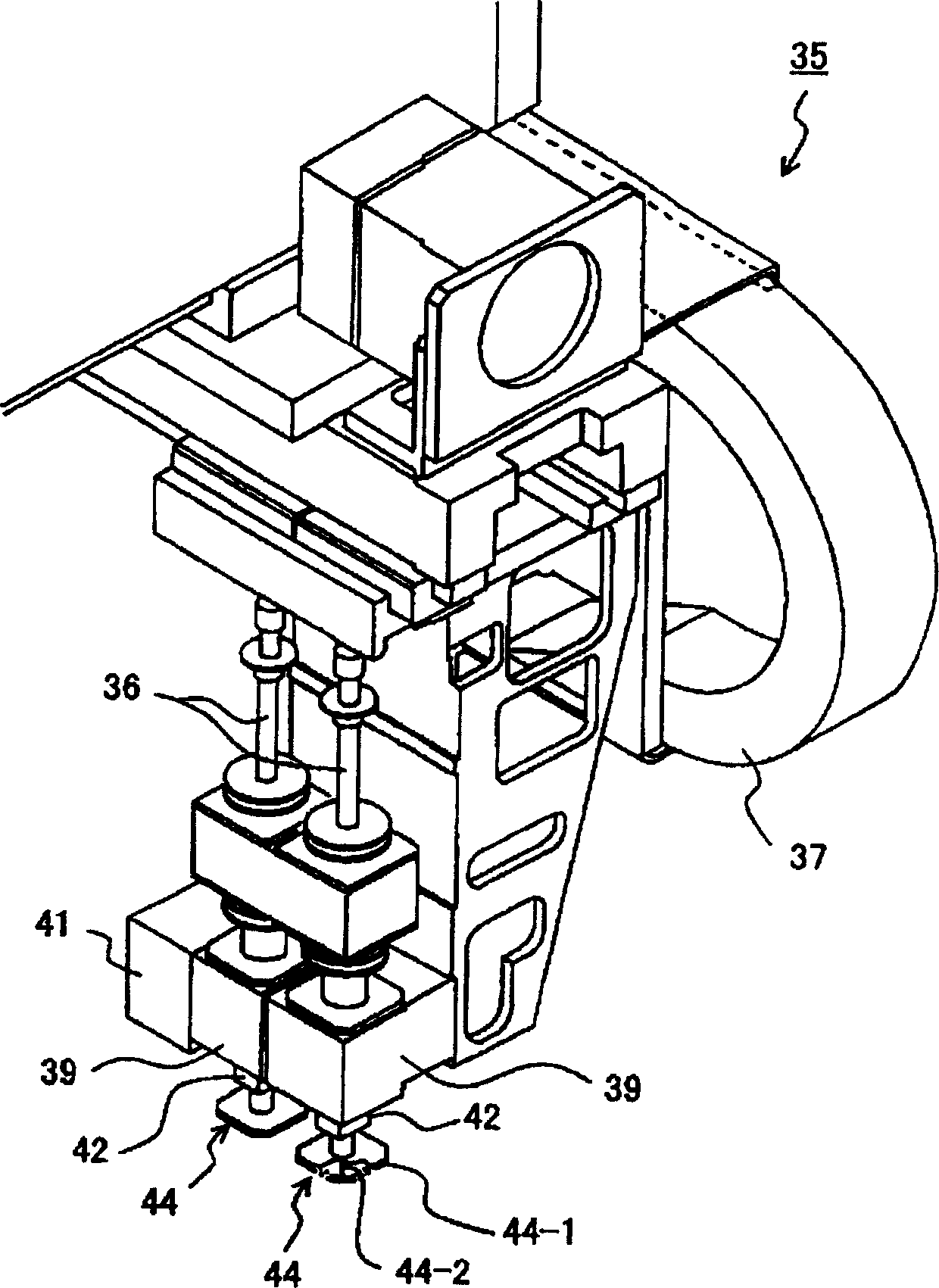

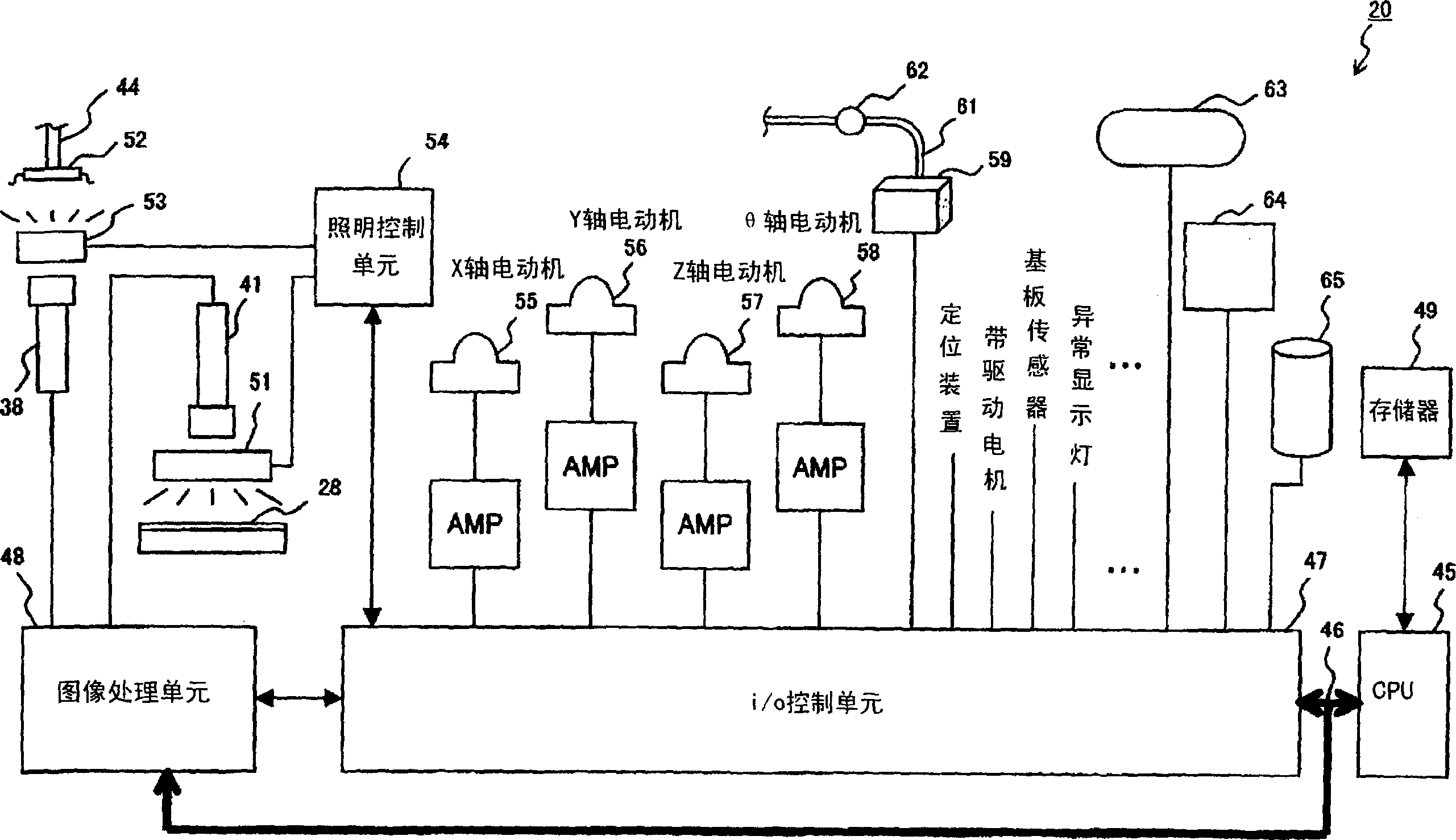

[0052] Fig. 1 (a) is a perspective view showing the appearance of an example of a component mounting device using an embodiment of the image data generation method of the present invention; Fig. 1 (b) schematically shows the internal structure after removing its upper and lower protective covers Oblique view.

[0053] As shown in Figure 1 (a), the component mounting device 20 has: a monitoring device 22, which is composed of CRT (Cathode ray tube: cathode ray tube) located at the front and rear of the top cover respectively; The left and right on the top are used to report each operating status. And, on the surface of the front part and the rear part of the upper protective cover 24, the display device 25 for operation input is arranged, and it is composed of a liquid crystal display and a touch input device, and various instructions can be input by means of operations from the outside ( The display device 25 for operation input at the rear portion in the diagonally upward di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com