Sewing machine

A sewing machine and frame technology, which is applied to sewing machine components, sewing machine thread take-up devices, sewing equipment, etc., can solve the problems of increasing the outer diameter of the frame, high cost, and inability to implement large-scale components, and achieves miniaturization, The effect of reducing the amount of protrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

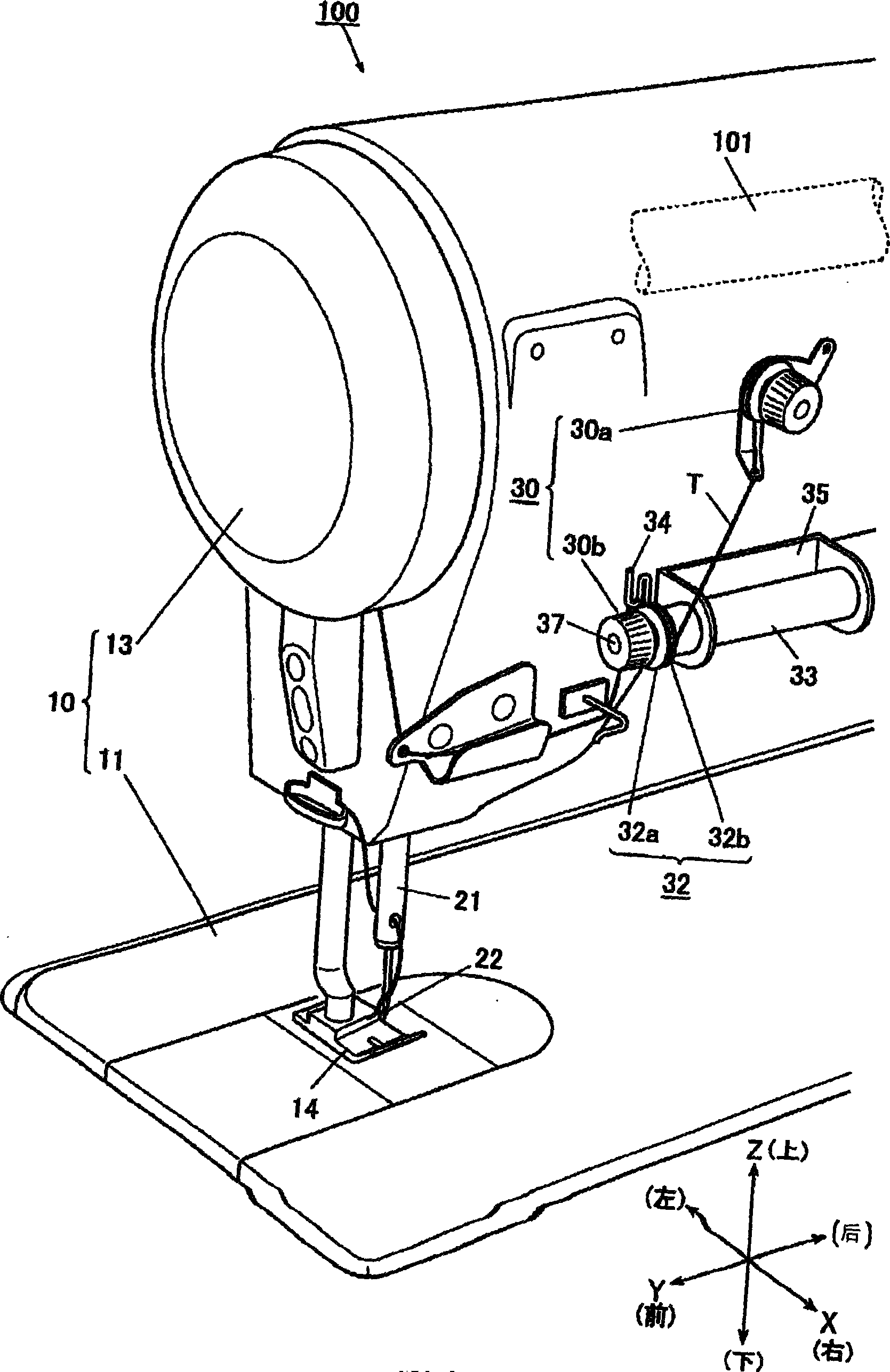

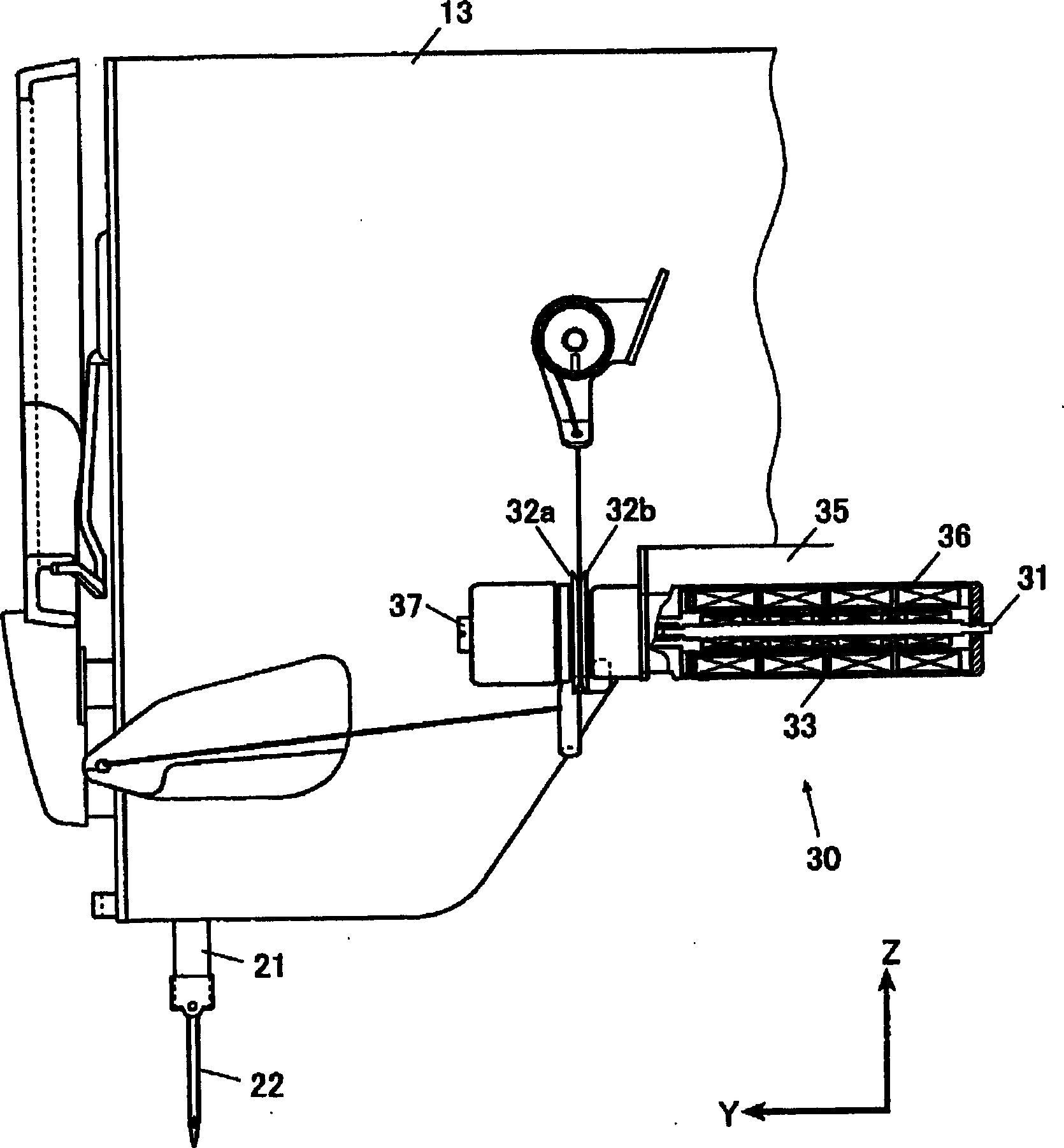

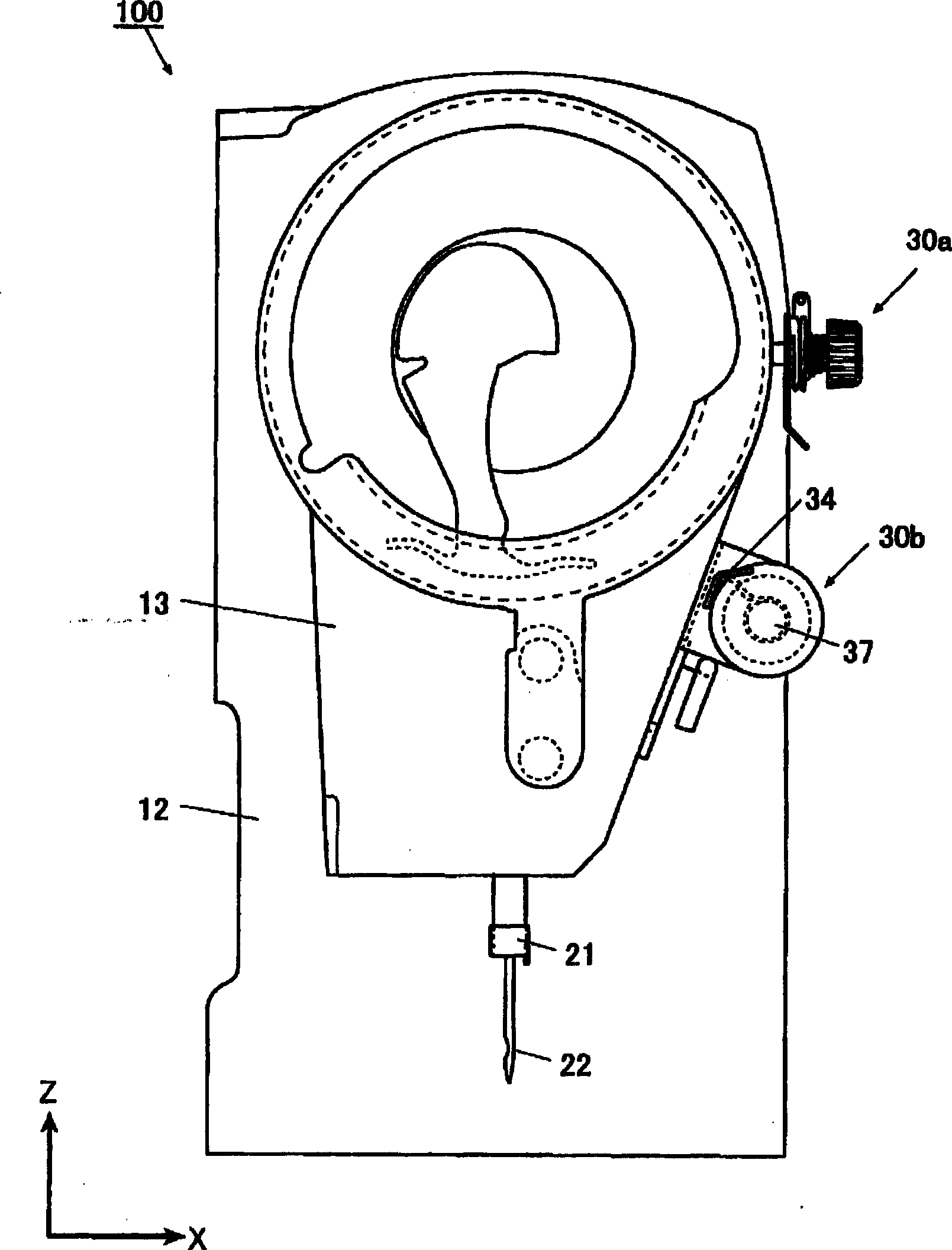

[0021] Below, based on Figure 1 ~ Figure 4 , the embodiment of the present invention will be described in detail.

[0022] In this embodiment, a lockstitch sewing machine will be described as an example of a sewing machine.

[0023] Here, the direction in which the needle 22 described later moves up and down is defined as the Z-axis direction (up-and-down direction), and the longitudinal direction of the machine head perpendicular thereto is defined as the Y-axis direction (front-rear direction). The direction perpendicular to both the Y-axis direction is defined as the X-axis direction (left-right direction).

[0024] (Overall configuration of the embodiment)

[0025] figure 1 It is a perspective view showing the configuration of main parts of the sewing machine 100 of the present embodiment.

[0026] Such as figure 1 As shown, a lockstitch sewing machine 100 (hereinafter referred to as sewing machine 100) is composed of the following main parts: a sewing machine frame ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap