No-voltage difference single iron core low wastage 12P rectification switch and manufacturing method

A single-core, rectifying transformer technology, applied to conversion equipment that can be converted to DC without intermediate conversion, transformer/inductor circuits, preventing/reducing unwanted electric/magnetic influences, etc.

Inactive Publication Date: 2006-10-11

卢建军

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

3.2 Y / △turn ratio selection and voltage deviation value and other data

Method used

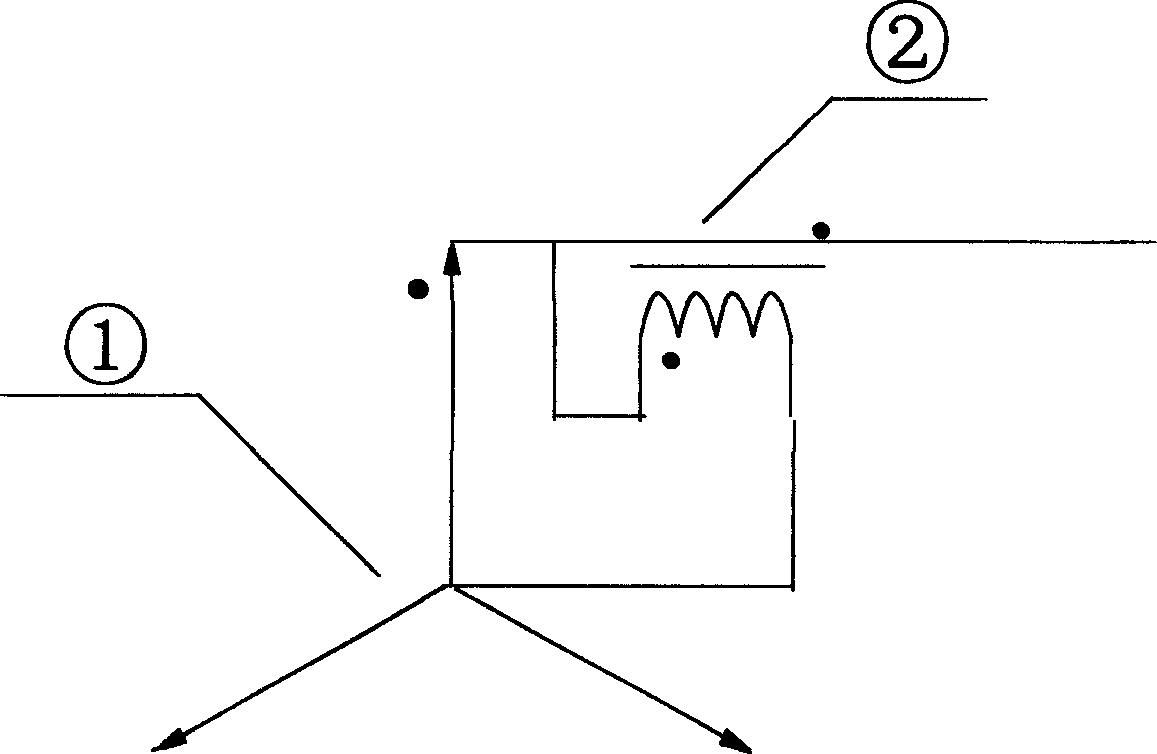

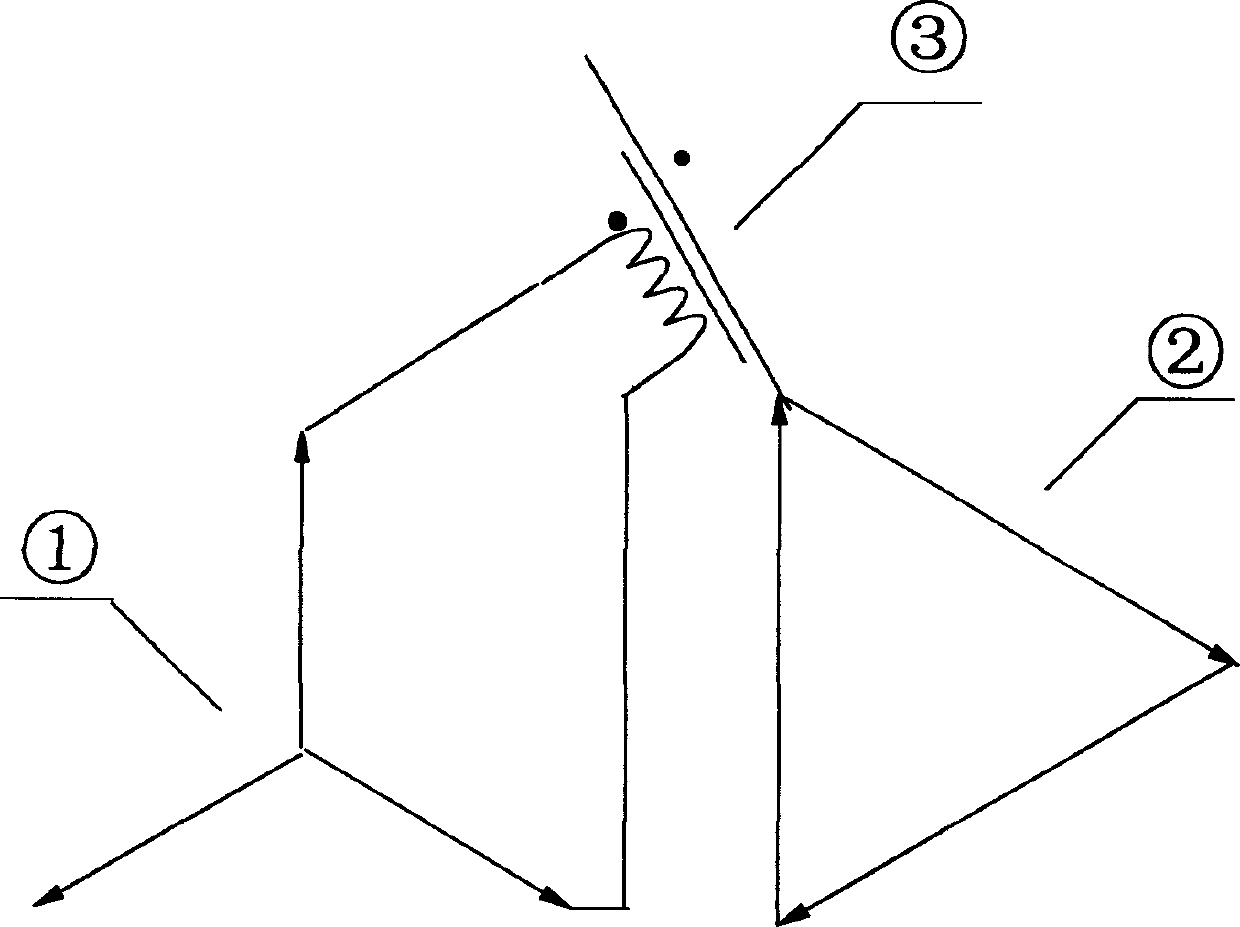

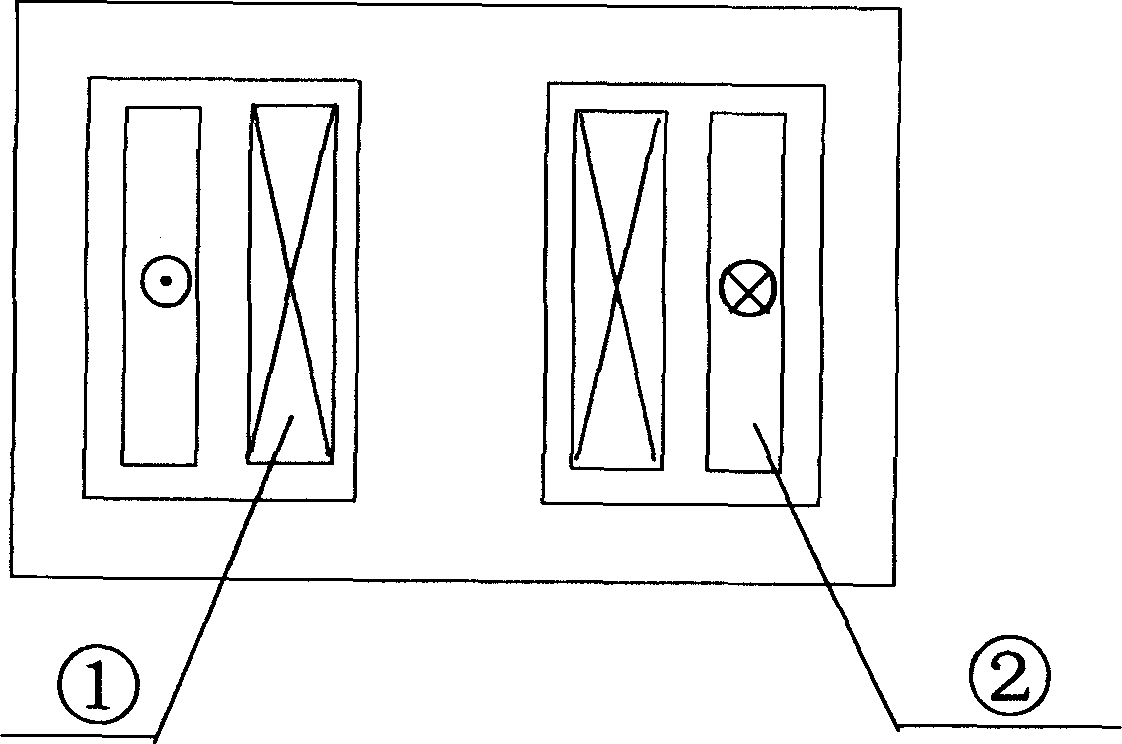

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

Unlike to prior art, in the invention, series connecting additional voltage of an auxiliary transformer to the single-iron-core 12P rectification transformer to balance Y-delta voltage and obtain high-voltage single-winding power transformer. This product overcomes the bias that it is hard to process the Y / delta winding number ratio as 1:3, and reduces loss consumption than the conjugated or dual-iron-core 12P rectification transformer.

Description

1 Technical Field The present invention relates to the technical field of high-power rectifier transformers 2 background technology 2.1 Introduction to the "China Chlor-Alkali Rectification Technology Advanced Training Course" in October 2003 2.1.1 Chlor-Alkali Association's choice of equivalent rectification phase number Since the frequency of the higher harmonic current generated by the rectifier equipment mainly depends on the number of rectified phases of the rectifier equipment (that is, the number of rectified pulses P), and the absolute value of the higher harmonic current I n It is inversely proportional to frequency. Therefore, increasing the number of equivalent rectified phases is the most effective measure to eliminate low-frequency harmonic currents with large absolute values. The rectifier circuits used in medium and large rectifier equipment are mainly three-phase bridge type and double reverse star type with balanced reactors. When using a double reverse star cir...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H02M5/10H01F27/38H01F27/42

Inventor 卢建军

Owner 卢建军

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com