Passenger conveying appliance

A technology for passenger conveying devices and control devices, which is applied in transportation, packaging, escalators, etc., and can solve the problems of rising costs, poor operability, and complicated maintenance and operation steps of passenger conveying devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

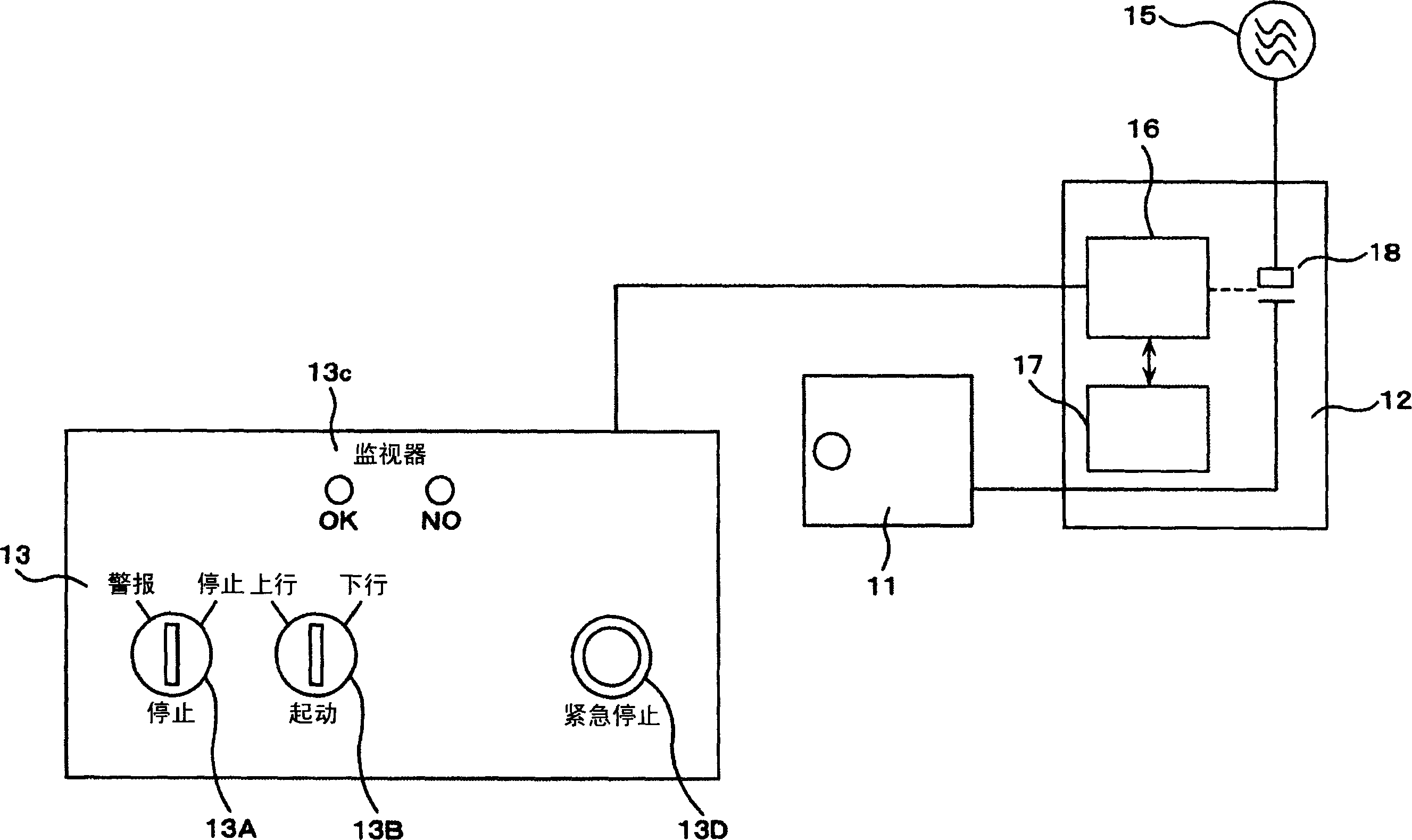

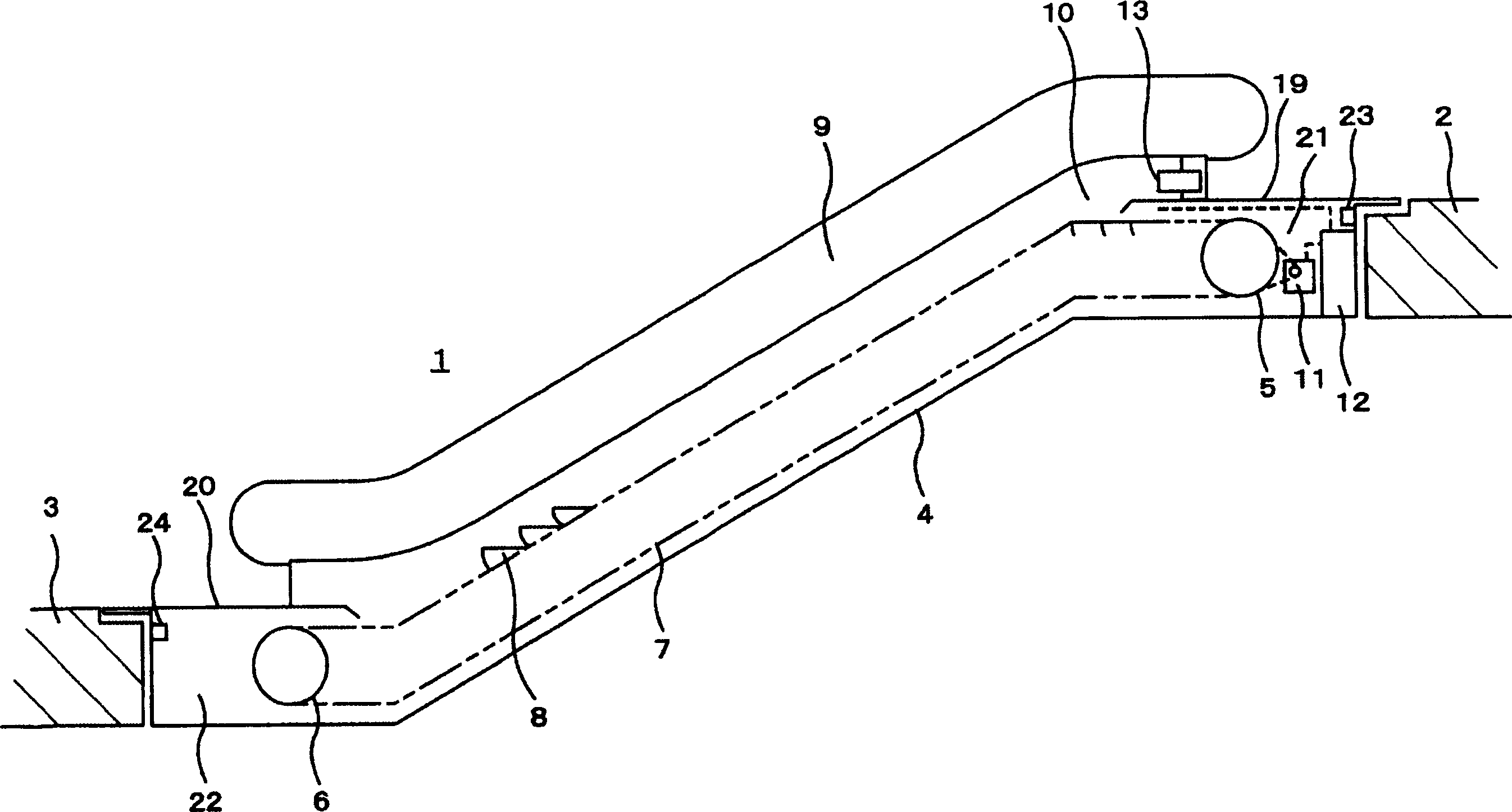

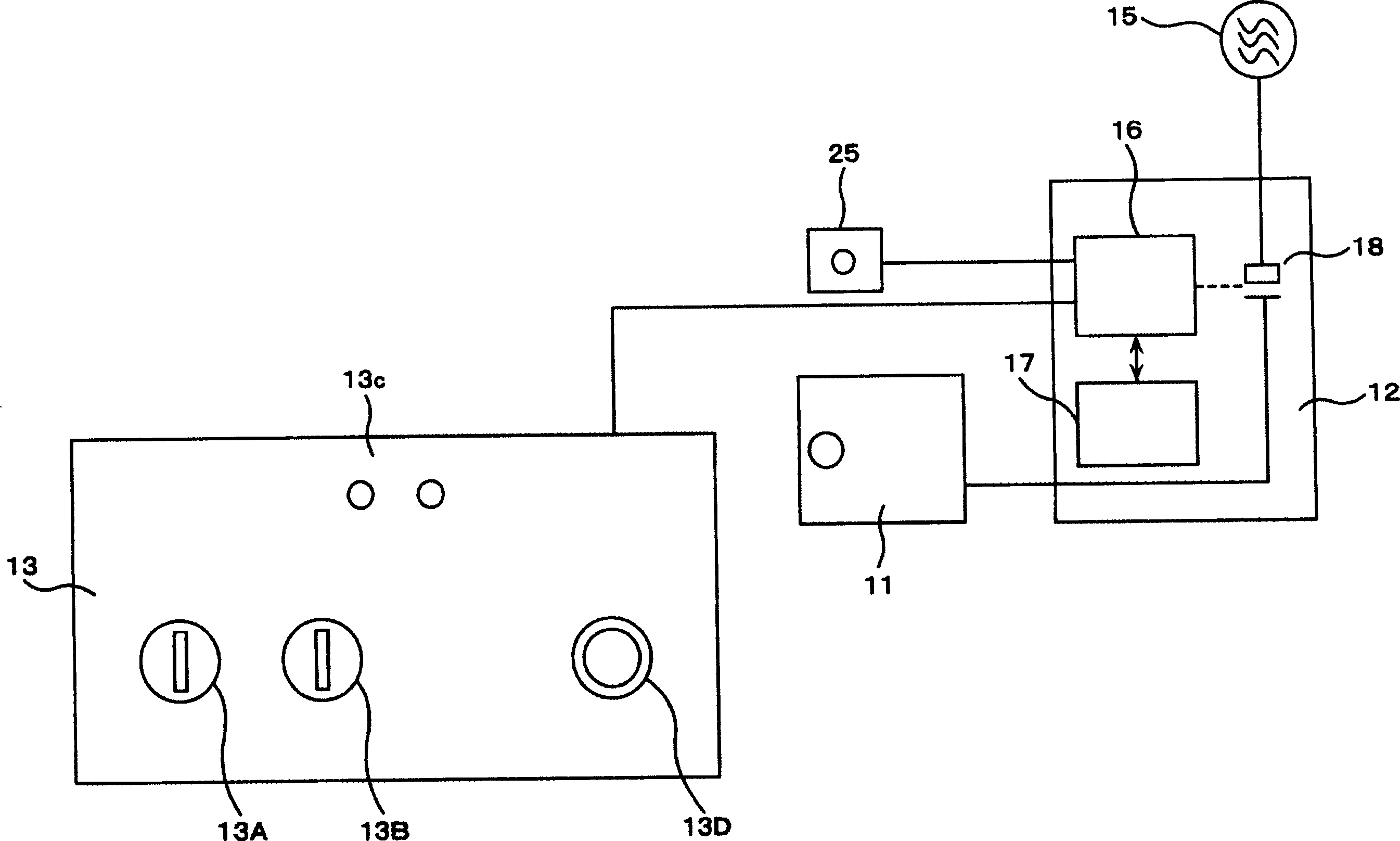

[0017] based on the following Figure 1 and Figure II The shown escalator describes the first embodiment of the passenger conveying device according to the present invention.

[0018] Figure II The whole structure of the escalator which concerns on 1st Embodiment of this invention is shown. Such as Figure II As shown, the escalator 1 is equipped with a main frame 4 straddling the upper floor 2 and the lower floor 3, a drive sprocket 5 and a driven sprocket 6 supported on both ends of the lengthwise direction of the frame 4 with shafts, and an annular coil A stepped chain 7 wound around the drive sprocket 5 and the driven sprocket 6, and a plurality of pedals 8 annularly connected to the stepped chain 7. In addition, the escalator 1 further includes railing panels 9 vertically provided on both sides along the moving direction of the pedals 8 , and guard skirts 10 that partition the pedals 8 covering the bases of the railing panels 9 and the railing panels 9 . An upper ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com