Amlexanox oral membrane, and its preparing method

A technology of aminolexanol and oral film, which is applied in the field of pharmaceutical preparations for treating oral diseases, and can solve the problems of difficulty in adapting to patients with oral ulcers, inconvenient use of pastes, instability of aminolexanol, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

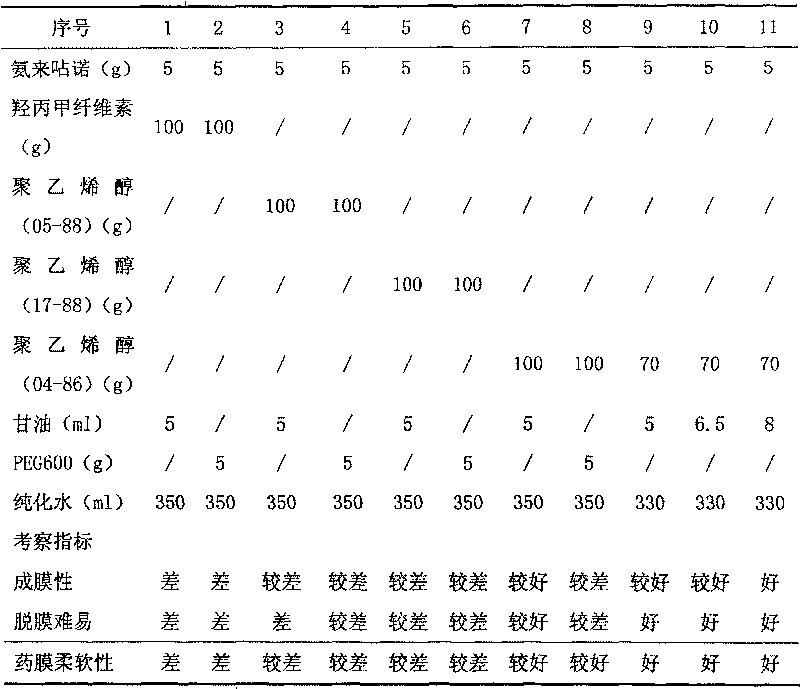

Method used

Image

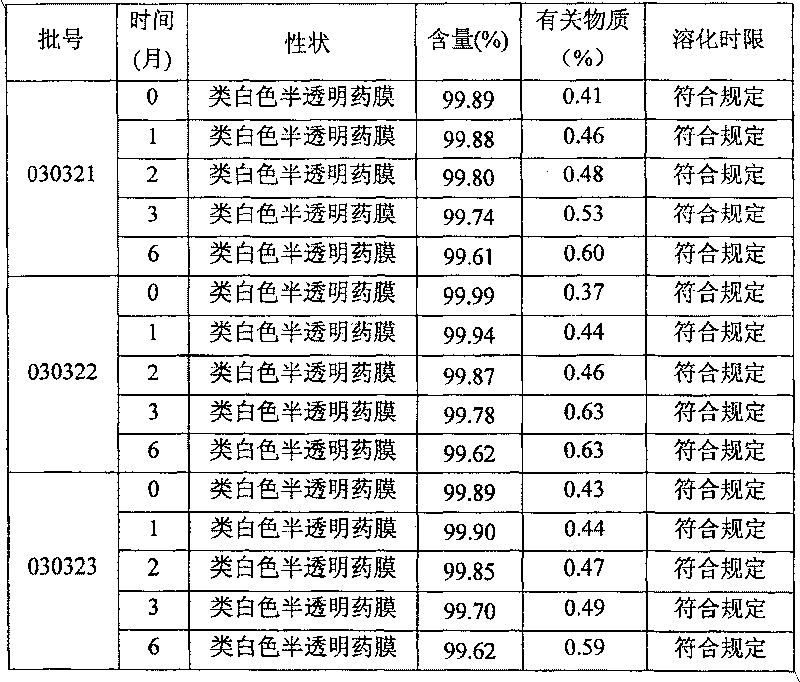

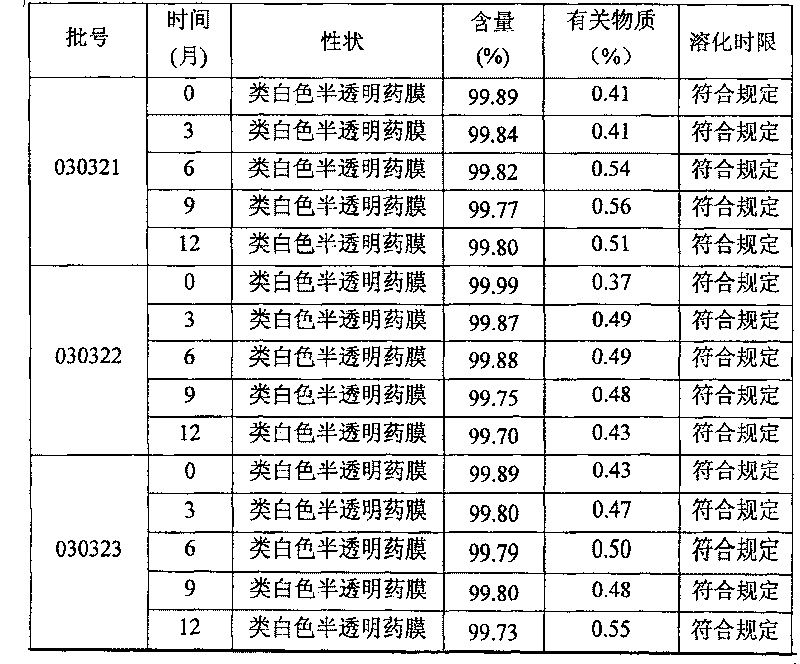

Examples

Embodiment 1

[0097] Amlexanol 5g

[0098] Polyvinyl alcohol (04-86) 70g

[0099] Glycerin 8ml

[0100] Purified water 330ml

[0101] Make 1000 sheets

[0102] Preparation Process:

[0103] 1. Amlexanox is crushed and passed through a 120-mesh sieve, and set aside;

[0104] 2. Grind the prescribed amount of amlexanox and glycerin with an appropriate amount of purified water to form a paste;

[0105] 3. Weigh the prescribed amount of polyvinyl alcohol and add purified water to swell, and heat to dissolve;

[0106] 4. Add the paste obtained in step 2 to the solution obtained in step 3, and mix well;

[0107] 5. Seal the suspension and place it in a 60°C environment for heat preservation and defoaming;

[0108] 6. Coating film;

[0109] 7. After the film is dried, the intermediate product is tested;

[0110] 8. Cut according to the content;

[0111] 9. Full inspection, packaging, storage.

Embodiment 2

[0113] Amlexanol 3g

[0114] Polyvinyl alcohol (04-86) 70g

[0115] Glycerin 8ml

[0116] Purified water 330ml

[0117] Make 1000 sheets

[0118] Preparation Process:

[0119] 1. Amlexanox is crushed and passed through a 120-mesh sieve, and set aside;

[0120] 2. Grind the prescribed amount of amlexanox and glycerin with an appropriate amount of purified water to form a paste;

[0121] 3. Weigh the prescribed amount of polyvinyl alcohol and add purified water to swell, and heat to dissolve;

[0122] 4. Add the paste obtained in step 2 to the solution obtained in step 3, and mix well;

[0123] 5. Seal the suspension and place it in a 60°C environment for heat preservation and defoaming;

[0124] 6. Coating film;

[0125] 7. After the film is dried, the intermediate product is tested;

[0126] 8. Cut according to the content;

[0127] 9. Full inspection, packaging, storage.

Embodiment 3

[0129] Amlexanol 2g

[0130] Polyvinyl alcohol (04-86) 70g

[0131] Glycerin 8ml

[0132] Purified water 330ml

[0133] Make 1000 sheets

[0134] Preparation Process:

[0135] 1. Amlexanox is crushed and passed through a 120-mesh sieve, and set aside;

[0136] 2. Grind the prescribed amount of amlexanox and glycerin with an appropriate amount of purified water to form a paste;

[0137] 3. Weigh the prescribed amount of polyvinyl alcohol and add purified water to swell, and heat to dissolve;

[0138] 4. Add the paste obtained in step 2 to the solution obtained in step 3, and mix well;

[0139] 5. Seal the suspension and place it in a 60°C environment for heat preservation and defoaming;

[0140] 6. Coating film;

[0141] 7. After the film is dried, the intermediate product is tested;

[0142] 8. Cut according to the content;

[0143] 9. Full inspection, packaging, storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com