Instrument for detecting flatness of round CD master-disc glass substrate

A technology of flatness detection and glass substrate, which is applied in the field of detectors, can solve the problems of affecting production efficiency, non-detection of rough surface, inconvenient use in large-scale production, etc., and achieve the effects of improved measurement accuracy, high work efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

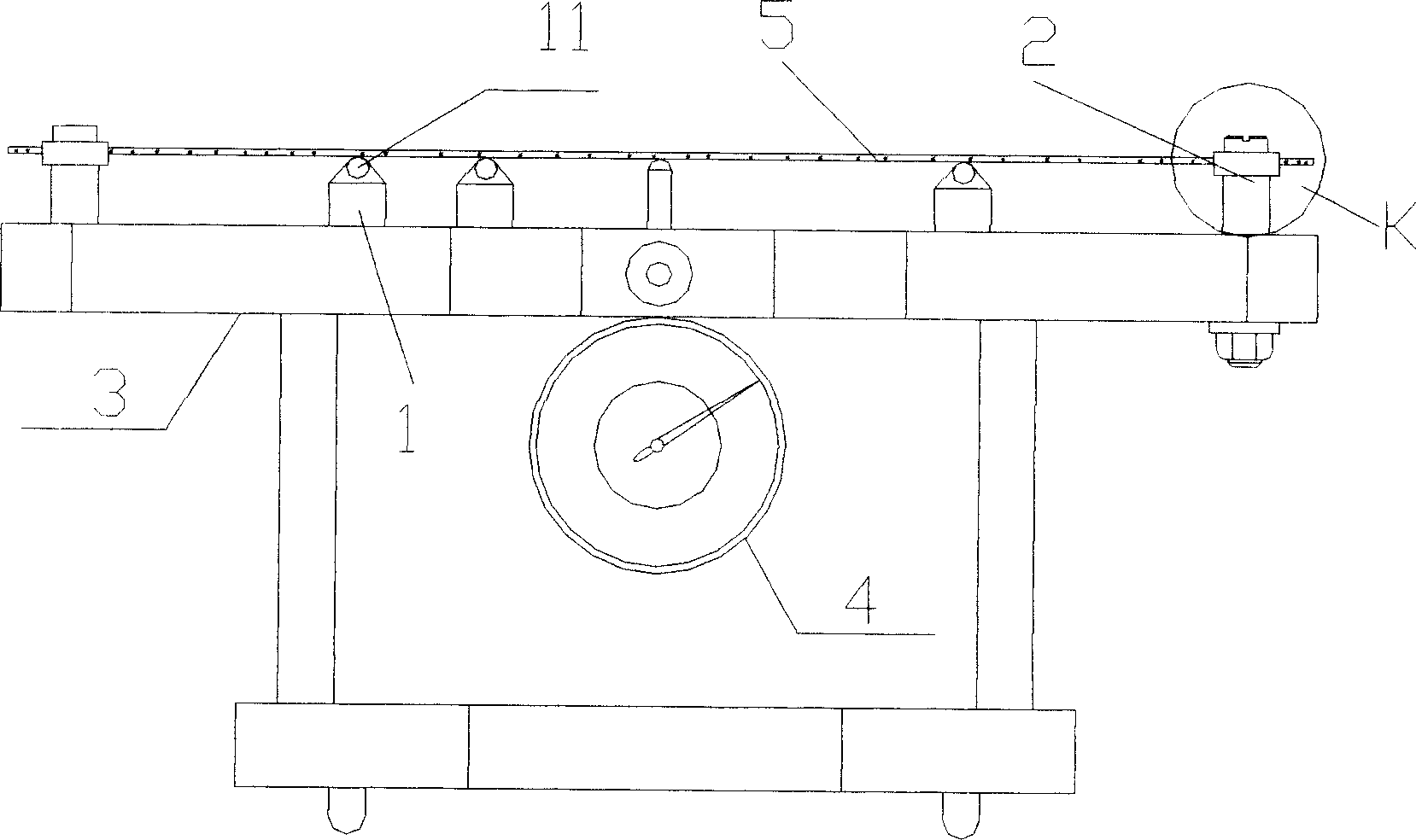

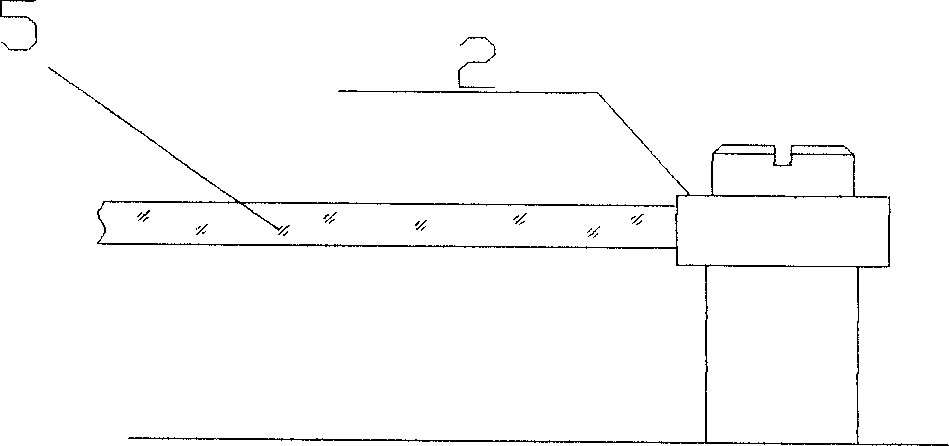

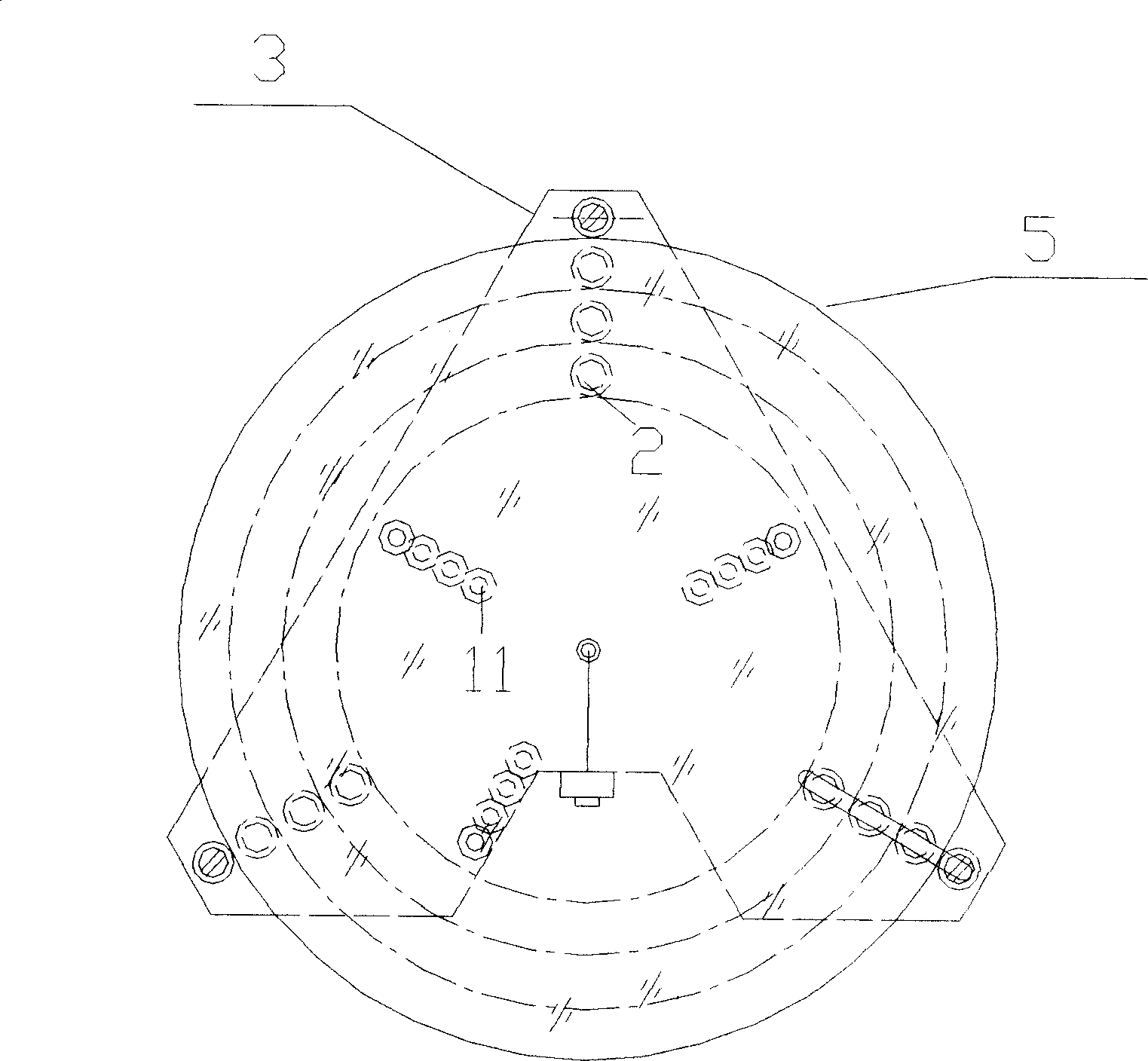

[0012] Depend on figure 1 , figure 2 , image 3 It can be seen that the present invention includes: a triangular work surface 3, three circular seats 1 are respectively arranged on the triangular work surface 3, and a small rotatable steel ball 11 is arranged on each circular seat 1; A group of small ball bearings and fixed bases 2 are evenly distributed on the edge triangular positions of the work table 3; a dial indicator 4 is placed under the central position hole of the triangular work table 3;

[0013] The said round seat 1 can be adjusted in stages, and its corresponding small ball bearing and even the fixed seat 2 can also be adjusted in stages; the said stage can be 2 or 3 or 4;

[0014] There is a triangular work surface above the base of the present invention, and the scientific principle of determining a plane is made o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap